Strength and durability of materials are a critical part of quality control in industries, and this is where a Compression Testing Machine (CTM) becomes essential. It plays a central role in determining the compressive strength, deformation characteristics, and structural stability of materials such as concrete, metals, plastics, and composites.

A CTM machine is widely used across industries, including construction, automotive, aerospace, and manufacturing, to ensure product safety, quality, and compliance with international testing standards. This guide provides an overview of the full form of CTM, explores the different types of CTM machines, and highlights its most common and essential uses in industrial and research applications.

What is a Compression Testing Machine?

A compression testing machine is used to measure the compressive strength of materials and to evaluate their behavior under compressive loads. CTM machines are designed to determine the force a material can bear before deforming or failing, providing essential metrics like compressive strength, elasticity, and load-bearing capacity.

The CTM machine is widely used in construction, manufacturing, and materials research, ensuring product reliability and compliance with industry standards. It records the strength, deformation, and response of the material when crushed under loads.

For example, in construction, a compression test is used to assess whether concrete can meet load-bearing requirements. This is done by crushing the sample and measuring the maximum load it can withstand before failure.

What is CTM Full Form

CTM stands for Compression Testing Machine. It is a mechanical testing device used to apply a controlled compressive force to determine strength, deformation characteristics, and failure point of a material. CTM machines are widely used in construction, manufacturing, and materials research industries.

Compression Testing Working Principle

The compression testing machine principle works on applying a gradually increasing compressive load to a specimen placed between two platens. It measures the material’s resistance to deformation or failure to determine properties like compressive strength, yield point, and elasticity.

The load and the displacement are measured by the machine, using the following properties –

-

Compressive strength

-

Elastic limit

-

Yield point

-

Modulus of elasticity

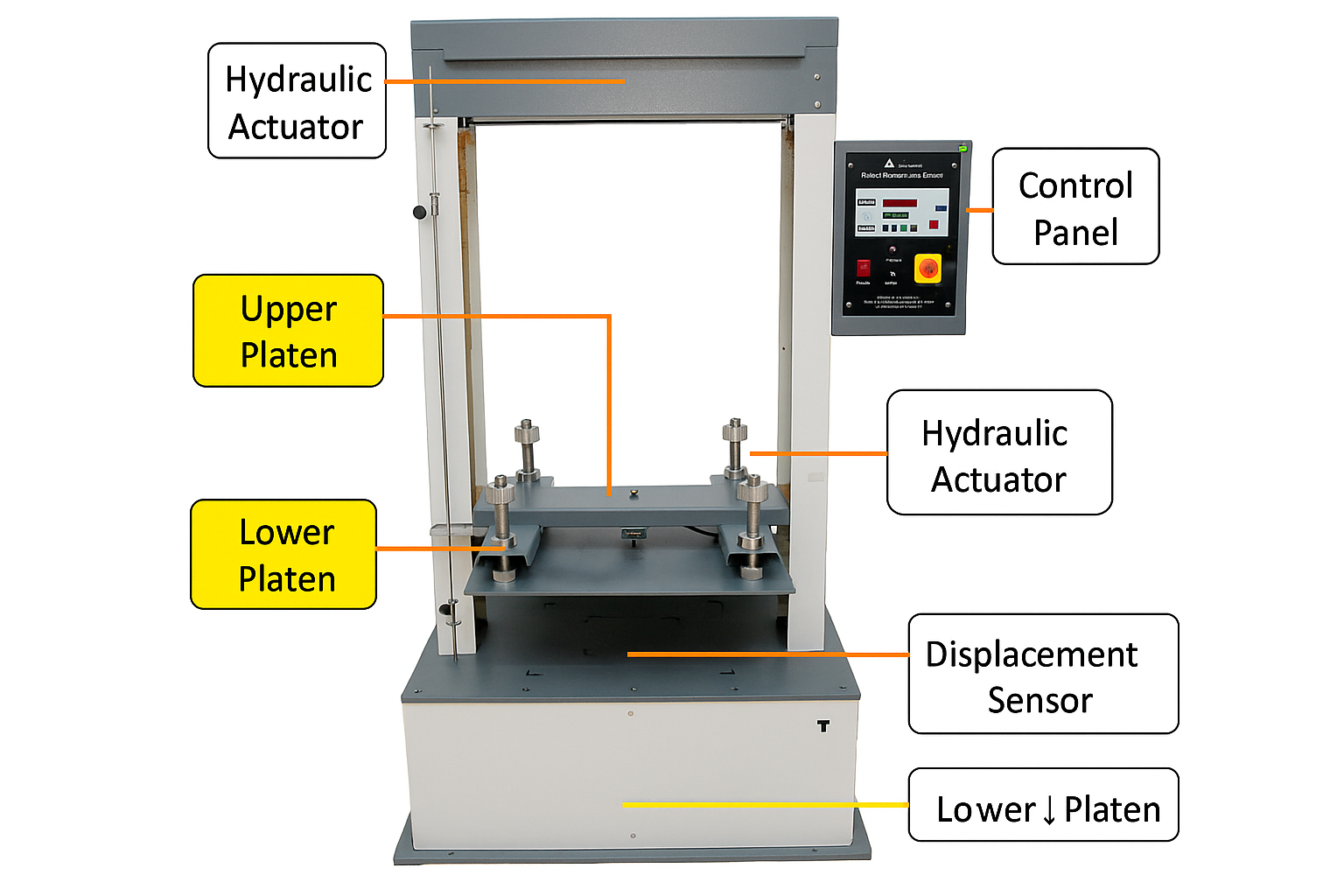

Compression Testing Machine Diagram and Components

A compression testing machine diagram shows essential components such as the upper and lower platens, crosshead, hydraulic actuator, load cell, and displacement sensor. The main parts of a compression test machine are detailed below:

Load Frame

-

Purpose: Offers structural support for the entire machine components.

-

Construction: Constructed using high-strength steel or cast iron to be able to resist heavy loads without deforming.

-

Design: Can be printed in single-column or dual-column depending on the load capacity and test type.

Upper and Lower Platens

-

Upper Platen: Fixed on the moving crosshead or hydraulic ram. Exerts compressive force on the top surface of the test specimen.

-

Lower Platen: A stationary base upon which the test specimen rests while being compressed.

-

Material: Hardened steel for resistance and to provide equal load distribution.

-

Optional Feature: The Platens of some machines slightly rotate in order to self-align and provide uniform contact.

Crosshead (Movable or Fixed)

-

Function: Moves upward or downward to vary the platens' distance and provide pressure.

-

Adjustment: May be adjusted manually, hydraulically, or through a servo motor based on the type of machine.

Hydraulic or Electromechanical Actuator

-

Hydraulic Actuator: Typical for high-capacity machines, employs pressurized oil to develop compressive force.

-

Electromechanical System: Employs motors and lead screws for controlled force application, particularly in laboratory environments.

Load Cell

-

Function: Monitors the actual force imposed on the specimen.

-

Location: Placed inside or below the compression system.

-

Output: Transmits real-time force to the digital monitor or control software.

Displacement/Deformation Sensor (LVDT)

-

Function: Quantifies the amount of shortening of the specimen during the test.

-

Significance: Facilitates the creation of stress-strain plots and assists in the determination of modulus of elasticity.

Control Panel / User Interface

The following are the control panels used in the compression test machine:

-

Manual Controls: Used in simple machines, which can have knobs and analog dials.

-

Digital Controls: Advanced machines provide touch screen terminals, automatic settings, and data logging.

-

Display: Displays load, deformation, test time, and calculations of results.

Data Acquisition System

-

Software Interface: Contemporary machines are connected to a computer, upon which testing software captures data and prints out reports.

-

Functions: Plotting of graphs, automatic computation (e.g., compressive strength), and storing test history.

Types of Compression Test Machine

There exist two primary categories of compression testing machines, i.e., hydraulic and servo-electric. A hydraulic compression testing machine is the traditional and most widely used compression testing machine. They work by utilizing hydraulic fluid to develop the force needed to test in compression.

Hydraulic compression testing machine

A hydraulic compression testing machine is the older and more widely used one. Hydraulic fluid is utilized to produce the force necessary for compressive testing in them. The hydraulic fluid is forced through a pump, which in turn drives the machine's piston to exert force on the specimen. These machines are able to produce extremely high forces and are appropriate for heavy-duty test applications.

Servo-electric compression testing machines

Servo-electric compression testing machines are newer and more sophisticated machines. They utilize electric motors to create the force required for testing, and their force application is more accurate and precise compared to hydraulic machines. Servo-electric machines are more energy-efficient compared to hydraulic machines, hence more sustainable.

What is a Compression Testing Machine Used for?

A Compression Testing Machine (CTM) is used to determine the compressive strength of a material. The CTM is constructed to produce a compressive load on the sample until it breaks. The machine has a piston that reciprocates within a cylinder and applies the load to the sample.

Construction and Civil Engineering

In construction and civil engineering, compression testing machines assess the strength of concrete blocks, bricks, and mortar to ensure structural safety. They are also adapted for soil testing to measure compressibility and strength, providing vital data for foundation stability and load-bearing capacity.

Metallurgy and Manufacturing

In metallurgy and manufacturing, compression testing machines evaluate metals like steel, aluminum, and copper for resistance to buckling or crushing, critical for automotive, aerospace, and machinery parts. They also verify that forged components can withstand operational stresses, ensuring safety and durability in demanding applications.

Plastic and Rubber Industry

In the plastic and rubber industry, compression testing is used to study how thermoplastics, thermosets, and rubber respond to compressive stress. It also aids in validating product designs for items like seals, gaskets, and cushioning foams, ensuring performance and durability.

Packaging Industry

In the packaging industry, compression testing evaluates the strength of corrugated boxes and packaging materials to ensure they withstand stacking and shipping forces. It also assesses the load-bearing capacity of containers, determining the maximum weight they can support before collapsing.

Research and Development

In research and development, compression testing machines are used to study material deformation, failure mechanisms, and stress-strain behavior. Engineers also rely on these tests to validate new materials and prototypes, driving innovation and product improvement.

Compliance and Quality Control

In compliance and quality control, compression testing machines verify that materials meet industry standards like ASTM, ISO, BIS, or EN. Manufacturers also perform routine batch testing to ensure production quality and consistency before delivery.

How to Perform a Compression Test?

A compression test involves applying a controlled compressive load to a material or part until it fails or deforms. This test measures key mechanical properties, including compressive strength, yield strength, and deformation behavior.

Step 1: Prepare the Test Specimen

-

Shape and Size: Condition the specimen following applicable standards (e.g., ASTM, ISO). Typical shapes are cubes, cylinders, or rectangular blocks.

-

Surface Finish: Provide flat and parallel surfaces on top and bottom of sample for even load distribution.

-

Material Type: Apply proper specimen material—e.g., concrete, metal, plastic, rubber—based on the purpose of testing.

Example: For concrete, typical specimens are 150 mm cubes or 150mm diameter × 300mm high cylinders.

Step 2: Set the Compression Testing Machine

-

Machine Check: Check that the machine is in proper working condition.

-

Load Cell Calibration: Load cell calibration to ensure valid force measurement.

-

Zero Adjustment: Zero all indicators and digital displays prior to the test.

Step 3: Set the Specimen Properly

-

Alignment: Set the specimen onto the lower platen of the compression testing machine. Ensure it is centered so that the specimen is not subjected to eccentric loading.

-

Contact: Level the upper platen so that it only lightly touches the top of the test piece without loading it yet.

Step 4: Establish Test Parameters

-

Load Rate: Select a proper rate of loading according to standards (e.g., 0.25 MPa/s for concrete).

-

Maximum Load: Define the maximum force or displacement, based on the type of test (e.g., until failure or certain deformation).

-

Data Recording: Allow the data acquisition system or digital interface to capture force and displacement measurements during the test.

Step 5: Begin the Test

-

Begin Loading: Begin loading the compressive load progressively and evenly through the machine.

-

Monitor Readings: Monitor the load and deformation on the digital display or computer software in real-time.

Step 6: Monitor Material Behavior

-

Elastic Deformation: The material at first will deform but revert to its initial shape upon removal of the load.

-

Yielding and Failure: Eventually, the specimen will permanently deform or fail.

-

Load Drop: Sudden loss of load signifies material failure or crushing.

Step 7: Stop the Test

-

Automatic or Manual Stop: The machine can automatically stop on failure, or you can stop it manually when the specimen has obviously failed.

-

Unload and Remove: Let the force off slowly, and then remove the crushed or deformed sample safely.

Step 8: Analyze the Results

-

Compressive Strength Calculation:

Compressive Strength (MPa) = Maximum Load (N) / Cross-sectional Area (mm)?

-

Stress-Strain Curve: If the machine is digital, analyze the complete stress-strain curve to obtain the yield point, elastic modulus, and deformation behavior.

-

Comparison with Standards: Check whether the test results satisfy the desired quality or design specifications.

Conclusion

A compression test machine is a crucial piece of material testing equipment that enables industries to assess whether their materials meet specified strength levels when subjected to compression. Understanding the various types, components, and operational procedures of the machine is essential for accurate testing and quality inspection.

Whether testing concrete, metals, or polymers, the correct utilization of a compression test machine guarantees safety, compliance, and performance in actual application.

Also Read:

What is Laminar Air Flow?

What is Moisture Meter?

What is PH Meter?

What is Ash Value?

What is Compressive Strength?

What is ESCR?

What is a Water Bath?

What is Melt Flow Rate?