The pharmaceutical market is among the most heavily regulated industries globally, where precision, reliability, and compliance become priorities. To guarantee quality and safety, the pharmaceutical industry counts on sophisticated testing devices that are used to validate finished products, raw materials, and packaging. Entering 2026, the need for accurate, long-lasting, and compliant testing solutions grows.

Why Do You Need Pharmaceutical Testing Instruments

Pharmaceutical testing instruments are essential for ensuring medicine/drug safety, efficacy, and high quality while meeting stringent regulatory standards and protecting both product integrity and patient health. Equipment allows for accurate analysis of drug content, impurity detection, verification of dosage forms, and testing of stability.

Pharmaceutical test equipment guarantees:

-

Product safety and adherence to global standards.

-

Robustness of packaging during handling, storage, and shipment.

-

Reliable quality checks for consistency in production.

-

Trust of customers by established product reliability.

List of Pharmaceutical Testing Instruments

Drop Tester

A drop tester tests the durability of pharmaceutical packaging so that medicines are safe to be handled, shipped, and stored. It replicates free-fall drops from varying directions and heights to check the strength of cartons, blister packs, and bottles. This avoids breakage, spillage, and product loss during transportation.

Key Specifications of Drop Tester:

-

Drop height Min. 750 mm, Max 1800mm

-

Up to 60kg maximum weight of the box to be tested

-

950*650 mm base dimensions

-

Motorized automatic flap movement through remote

-

Motorized dropping platform lift structure

Muffle Furnace

A muffle furnace is a necessary piece of equipment in pharmaceutical lab testing for ashing, decomposition of material, and heat treatment procedures. It offers even high-temperature heating to analyze organic and inorganic substances. Used extensively for gravimetric testing and quality control, it enables accurate testing of raw materials and finished drug products under controlled conditions.

Also reed: What Is Muffle Furnace?

Key specifications of Muffle Furnace:

-

Inner Chamber Size- • 4 x 4 x 9 Inch, 5 x 5 x 10 Inch, 6 x 6 x 12 Inch

-

Display a 7 Segment LED display

-

Temperature Range Ambient to 900ºC, 1200 C & 1400 C

-

Least Count/Resolution 1ºC

-

Power 20A,220VAC

Tensile Strength Tester

The tensile strength tester quantifies the mechanical strength of drug packaging materials like blister foils, laminates, and films. It measures the ultimate tensile force a material can endure without failing, which guarantees packaging reliability and protects the patient. It further assists manufacturers in adhering to regulatory requirements for quality packaging.

Key specifications of Tensile Strength Tester:

-

Accuracy – ±0.5% of Load Cell Capacity

-

Travel distance of the grips – 25mm – 700mm.

-

Motor – 1/5 HP, 1440 rpm, 1-phase power supply.

-

Grip to grip separation: Min 25mm and max 700mm

Box Compression Tester

Box Compression Tester tests the compressive strength of drug shipment boxes. It verifies whether boxes are able to support stacking pressure, storage, and transportation without folding. The test protects drugs from crushing injury, contamination, or spillage while preserving product integrity during the entire chain of supply.

Key Specifications of Box Compression Tester:

-

Extremely precise test results under consistent compression Force

-

TARE and Peak Hold Facility Present

-

Robust base plate with sturdy structure

-

POWER-220V, Single / Three phase, 50 Hz

-

LED digital display

Top Load Tester

The Top Load Tester finds the vertical load-bearing capacity of plastic pharmaceutical bottles, jars, and containers. It replicates stacking pressure during storage and transport, preventing deformation or leakage of containers. This is made to ensure dosage correctness and patient safety by preserving packaging integrity.

Key Specifications of Top Load Tester:

-

Max. Load Range: 100Kgf

-

Accuracy: ± 0.5% full scale (with master load)

-

Least Count/Resolution: 10gm

-

Power: 220V, Single phase, 50 Hz

-

Display: Digital & Graphical

Standards for Pharmaceutical Testing Instruments

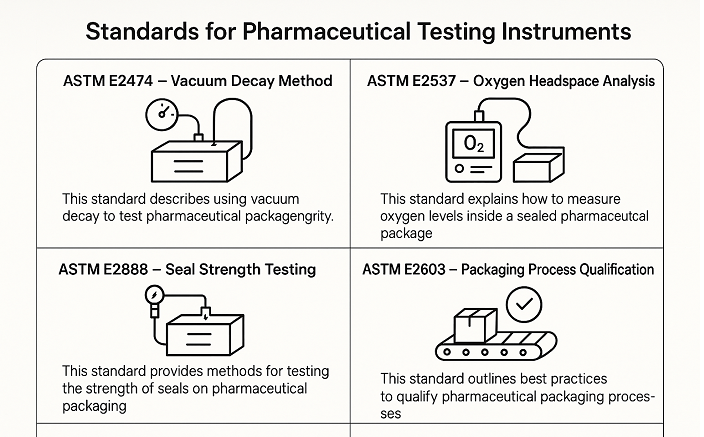

Here are some standards of pharmaceutical testing instruments described:

ASTM E2474 – Vacuum Decay Method

This standard describes using vacuum decay to test pharmaceutical package integrity. It detects leaks by creating a vacuum and checking for pressure changes, ensuring the packaging is airtight and protects the product from contamination or spoilage.

ASTM E2537 – Oxygen Headspace Analysis

This standard explains how to measure oxygen levels inside a sealed pharmaceutical package. High oxygen content can degrade medicines. The test ensures the packaging effectively blocks oxygen, maintaining drug stability and extending shelf life.

ASTM E2888 – Seal Strength Testing

This standard provides methods for testing the strength of seals on pharmaceutical packaging. It ensures the seals are strong enough to prevent leaks or contamination during handling, storage, and transport, helping maintain drug safety and quality.

ASTM E2503 – Packaging Process Qualification

This standard outlines best practices to qualify pharmaceutical packaging processes. It ensures packaging operations are consistent, effective, and meet quality standards, so that every package reliably protects the medicine throughout its intended shelf life.

ASTM F1980 – Accelerated Aging of Packaging

This standard describes how to use heat and time to simulate the aging of pharmaceutical packaging. It helps predict shelf life and ensures packaging materials remain effective over time in protecting drugs under real storage conditions.

Pharmaceutical testing equipment continues to play a pivotal role in guaranteeing drug safety, packaging integrity, and conformance to high global standards. Equipment such as drop testers, muffle furnaces, tensile strength testers, box compression testers, and top load testers not only protects medicine quality but also improves efficiency in production and shipping. Complying with ASTM standards, the pharmaceutical industry remains committed to patient safety and product excellence.

Testronix Instruments supports this commitment by offering reliable and precise pharmaceutical testing equipment designed to meet ASTM standards. With an experience of over a decade in the manufacturing of testing instruments, we focus on quality and innovation. Testronix helps manufacturers ensure packaging integrity and product safety throughout the supply chain.