Packaging integrity is very crucial in the pharmaceutical packaging business because it guarantees the safety, sterility, and long shelf life of the products. The containers, such as vials or blisters, may have microscopic leakages that allow contamination, destruction of potency, or regulatory non-conformity. A leak test apparatus is an extremely widespread quality control tool to prevent such issues by spotting leaks in the sealed pharmaceutical package before transporting the goods to the patients.

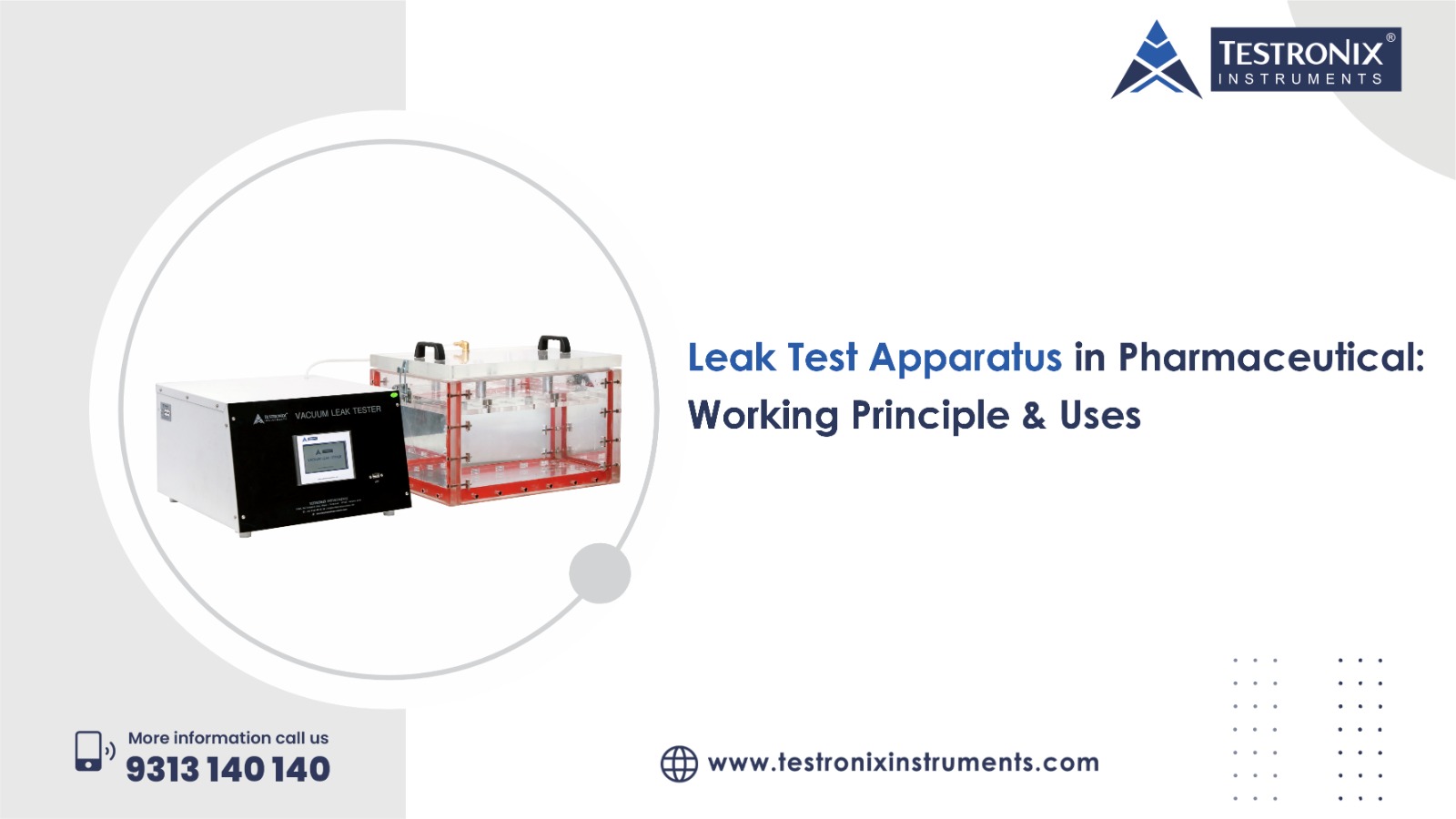

What is Leak Test Apparatus in Pharmaceutical Industry

A leak test apparatus in the pharmaceutical industry is a precise, microprocessor-managed apparatus that is utilized to check leakage in the wrapping of blister packs, strips, sachets, vials, and ampoules. The leak test is a vacuum under controlled conditions, and it is usually found in a clear acrylic desiccator with the aim of protecting the products against the effects of water and air, as well as microbes.

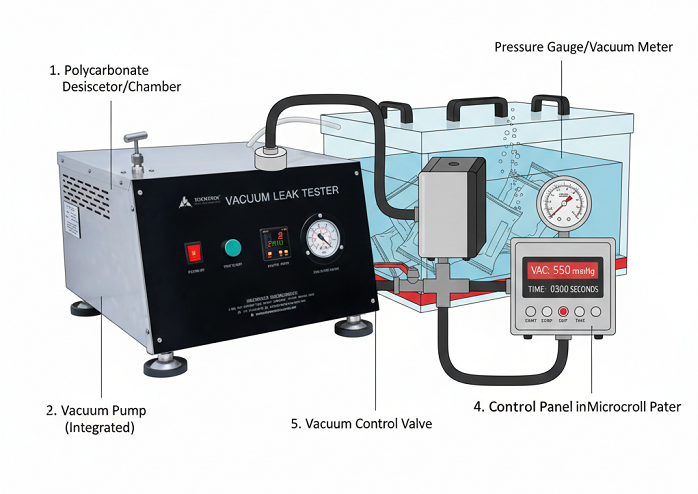

Leak test apparatus diagram and parts explanation

A Leak Test Apparatus consists of a transparent polycarbonate desiccator, a vacuum pump, a pressure gauge, and a control panel to create a negative pressure, forcing air out of defective seals, particularly inside a water bath.

Here are the components of the leak test apparatus explained:

-

Polycarbonate Desiccator/Chamber: This is a clear and fully closed container (jar) that holds the product and, optionally, water. Therefore, it enables the visualization of the bubbles in the liquid.

-

Vacuum Pump: This is a small, built-in device that generates a great vacuum within the desiccation chamber, thereby generating a difference in pressure.

-

Pressure Gauge/Vacuum Meter: This indicates the prevailing vacuum amount (usually in mm Hg or in kPa) at any point in time during testing to establish progress.

-

Control Panel/Microcontroller: Soft-touch buttons and LED display where test options are entered (e.g., vacuum level 200-600 mm Hg and time up to 9999 seconds).

-

Vacuum Control Valve: Offers an opportunity to detach the desiccator and the vacuum pump to be able to keep or release a previously predetermined time of holding a vacuum.

-

Timer: Used to guarantee that a vacuum will be maintained over a set amount of time.

Leak test apparatus working principle

The working principle of the leak test apparatus is based on the pressure differential, using either vacuum or pressure decay. Therefore, the unintentionally leaked gas/air is assessed as it moves through the seal. It does this by creating a differential in the pressure (vacuum on the outside or pressure on the inside). The device can detect and locate any leaks in the unit by measuring either the fluctuation in pressure or by detecting the presence of bubbles from the water, or even through the more sophisticated use of mass spectrometry.

How leak test apparatus works: step-wise guide

The leak test device works through several processes which include the preparation of the chamber, sample placement, chamber sealing, vacuum creation, leak observation, pressure release, data analysis, and recording of the data.

Prepare the Chamber

The chamber must be cleaned, dried, and decontaminated (e.g., of moisture, dirt, or dust) before vacuum testing can be done. Contamination will have adverse effects on the development of the vacuum and generate erroneous test results and damage to the samples under test, which are leaked.

Placing the Sample

The package or product needs to be placed carefully in the chamber. Depending on the method of testing, samples may need to be submerged in water for bubble detection or placed on a dry tray so they can be observed for expansion while under a reduced pressure environment.

Sealing the Chamber

Securely close the chamber's lid to create a completely airtight environment within the chamber. Creating a completely airtight environment within the chamber is critical to establishing a consistent vacuum. If there is any ambient air that comes into contact with the chamber as a result of poor sealing, this will adversely affect the performance of the vacuum and produce erroneous results when conducting a vacuum leak test.

Apply Vacuum

Using the controller, establish the desired vacuum pressure and turn the vacuum pump on. By removing the air from inside the chamber in a gradual fashion, the pressure difference created by the establishment of the vacuum can help identify leaks created in improperly sealed or defective packages.

Observe for Leaks

Watch the sample closely when observing the pressure decrease. During wet tests, air escaping from the sample will also be visible as bubbles in the water. During dry tests, loss of seal integrity will be indicated by visible swelling or deformation of the package.

Release Pressure

After the holding period has been completed, slowly release the vacuum from the sample using the control valve. This gradual release of pressure reduces the stress placed on the package and helps to prevent damage to the testing equipment as well as the sample.

Analyzing Results

Investigate the integrity of the tested packaging. Check for any signs of leakage (such as either dye or water entering), separation of the seal, or any deformation of the package. From your observations, you will be able to determine if the sample passes or fails to meet integrity requirements.

Document Data

Document test parameters (vacuum pressure and duration, observations, and pass or fail) during the testing process. Proper documentation is important for quality assurance purposes and regulatory compliance. It aids in the identification of recurring defects within packages when conducting audits.

Leak test apparatus uses in Pharmaceutical Industry

The leak test apparatus in the pharmaceutical industry ensures packaging integrity, sterility, and safety for products like blisters, strips, bottles, and vials.

Here are the uses explained in detail:

-

Blister Pack & Strip Integrity

Leak testing is applied to check the integrity of blister packs and strips of tablets/capsules. The tests will determine broken seals/pinholes/weak joints in blister packs/strips that might allow moisture/oxygen/contaminants into the products, rendering them less stable.

-

Vials & Ampoule Sealing

The Vial test contains a special test to check for the hermetic seal on the vials, ampoules, and aseptic bags of parenteral solutions. The proper seal prevents the entrance of bacteria and other microorganisms into the vial system and keeps the products sterile throughout the entire storage-and-handling process.

-

Bottle and Container Testing

The leak testing machine detects any possible leaks from a bottle made of plastic or glass, along with any dry syrup containers that may be inside it. This helps guarantee that all closures (lids), caps, or seals are functioning correctly and do not allow for any ships to be lost and/or contaminated during transport.

-

Sachet and Pouch Testing

Leak testing can help detect small holes and cracks in sachets and pouches that may not be apparent to the naked eye. These types of tests are particularly useful for packaging powders, liquids, and semi-solid materials when subjected to stress caused by their environment.

-

Quality Control and Compliance

Leak testing will allow manufacturers to verify that they have constructed their packaging to comply with international standards like USP <1146> and ASTM standards. The leak testing evidence gives a written account of the integrity of a package, which is critical in the audit process and regulatory approval.

Related: Quality Control vs Quality Assurance: Know the Difference

-

Packaging Process Optimization

Leak testing identifies and investigates the cause of repeated seal failures, ultimately leading to greater optimization of the packaging process. The leak test can pinpoint problems with sealing temperature, pressure roller, machine alignment, etc., which can lead to taking corrective steps to improve production efficiency and decrease product rejections.

Conclusion

The pharmaceutical industry depends on the leak test equipment to control quality. The leak test devices assist in the assurance of the safety, absence of contamination, and compliance of packages with all the existing regulatory norms, and, thus, product sterility. The pharmaceutical professionals have to know the contents of the leak testing equipment, the diagram of the equipment, how it works, and its applications in order to help them control the quality of the products produced. The correct usage of a leak test tool enables companies to preserve the quality of their goods, and it also protects the health of their consumers.