What is Impact Test Machine?

An Impact Test Machine is a specialized device used to evaluate a material's ability to withstand sudden, high-energy impacts. It measures the toughness and durability of materials when subjected to dynamic stress, providing critical data that helps determine their suitability for various applications. These devices are essential in product development, quality control, and safety guarantees in different industries such as aerospace, automotive, construction, and metallurgy.

Impact testing operates on a falling weight or pendulum principle, measuring absorbed energy to assess toughness and failure behavior. India has a wide range of manufacturers and prices, from simple manual testers to advanced automated systems. The actual choice depends on the required energy range, level of automation, and targeted testing standards.

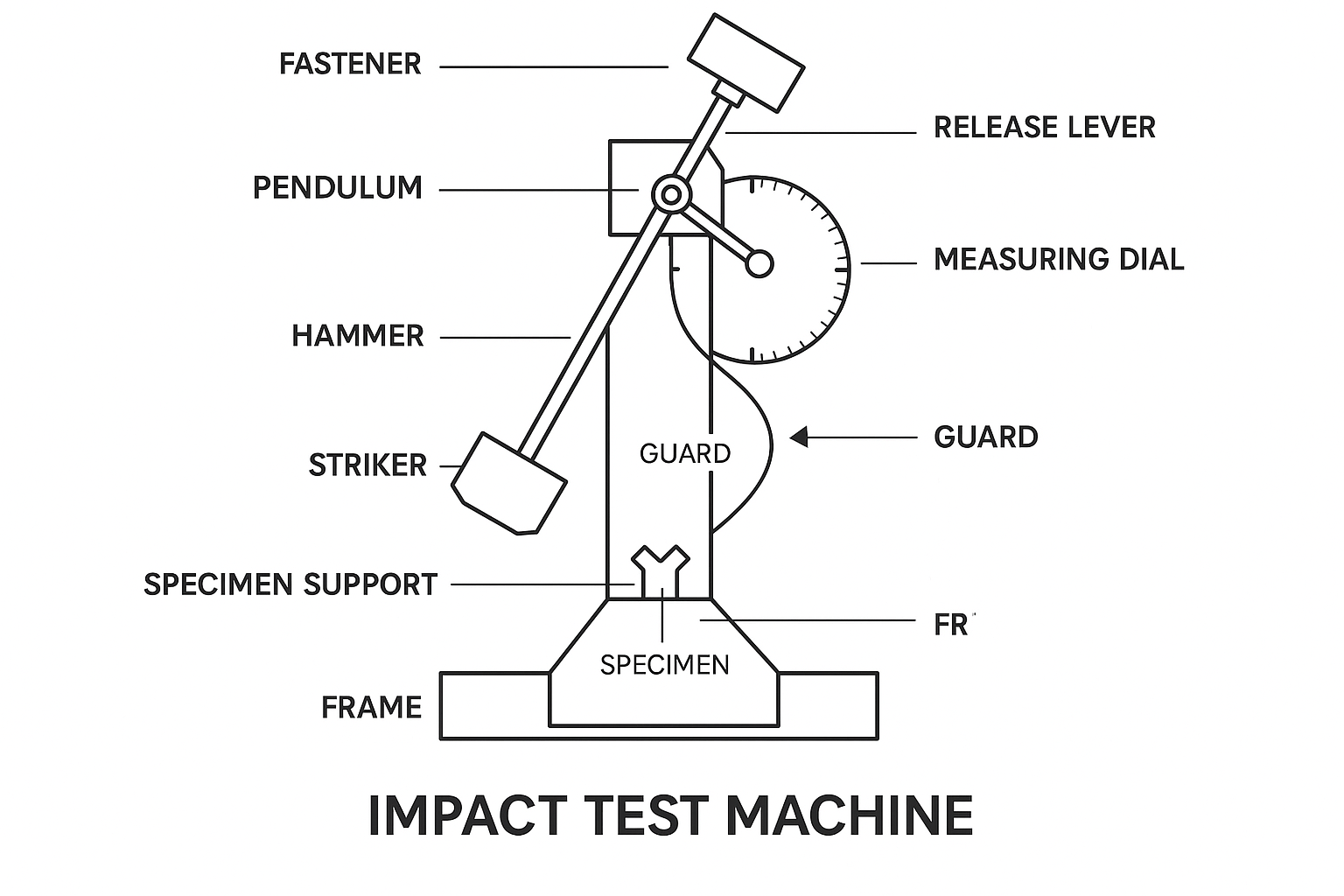

Impact Test Machine Diagram

An impact test machine diagram consists of a sturdy frame, a pendulum with an impact hammer, a support mechanism for the test specimen, and a dial for measurement. Additional components consist of a fastener for the pendulum, a lever to move it, a partially guarded swinging range with a guard, and a striker that strikes the specimen.

Important elements of an impact testing machine diagram are as follows:

-

Frame: A strong foundation for the machine, to ensure stability.

-

Pendulum: The moving component, a hammer and a lever arm.

-

Hammer: Weight at the end of the pendulum that impacts the specimen.

-

Striker: One component of the hammer that actually comes into direct contact with the test specimen.

-

Specimen Support: A holder that keeps the test specimen positioned in advance of impact.

-

Fastener: A device that restrains the pendulum to keep it in a raised position.

-

Release Lever: A lever to operate the latch release and start the test.

-

Measuring Dial: A concentric measuring dial showing the energy absorbed by the specimen following the impact.

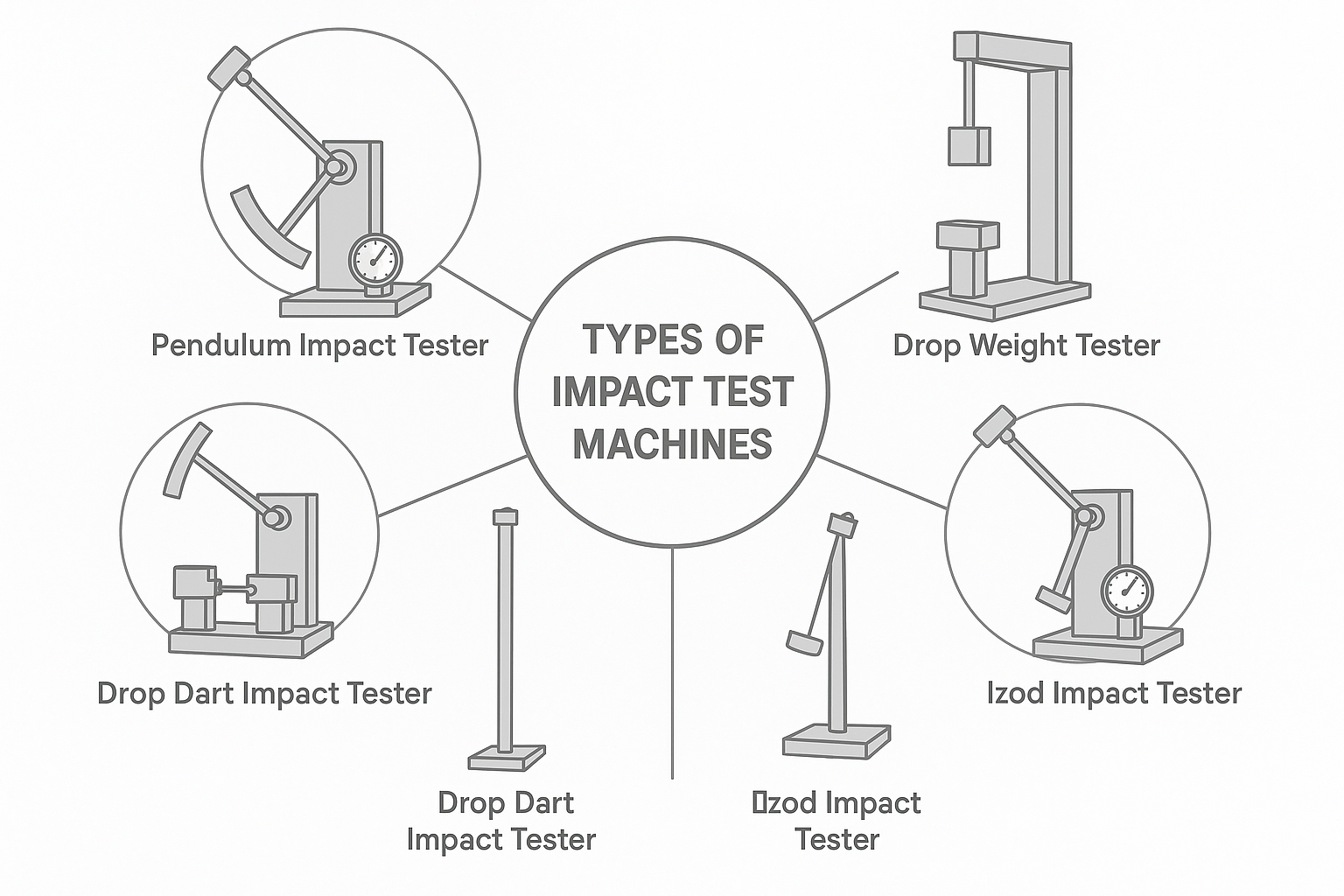

Types of Impact Test Machines

Pendulum Impact Testers

Pendulum impact testers employ a swinging pendulum to test a notched specimen and determine the energy absorbed in a fracture. They are found to be useful with metals and plastics, offering rapid and repeatable values of toughness. The dial gauge or digital system of the machine indicates the energy absorbed in joules.

Drop Weight Testers

Drop weight impact testers drop an unknown weight from a fixed distance onto a specimen to study its fracture characteristics. They are best suited to determine ductile-to-brittle transition temperature, fracture initiation and crack extension properties, particularly in pipeline steel, weldments, and materials subjected to sudden dynamic loading.

Charpy Impact Tester

The Charpy impact tester positions a notched specimen horizontally in the middle between two anvils and hits it using a swinging pendulum. It takes energy to shatter the specimen as a measure of the material's toughness. It is extensively used in metals to examine temperature influence and ductile-to-brittle transition behavior.

Drop Dart Impact Tester

Drop dart impact testers are typically applied to plastic films, sheets, and packaging materials. A hemispherical dart is dropped from a specific height until the sample breaks. This test measures impact resistance, puncture strength, and thin materials' energy absorption ability, which are utilized in flexible packaging applications.

Izod Impact Tester

The Izod impact tester supports the notched specimen as a cantilever beam in the vertical direction. The pendulum hits the upper end, resulting in a fracture. Impact toughness is measured as absorbed energy. It is commonly utilized for plastics, composites, and polymers to assess their resistance to sudden impact forces.

How Impact Test Machine Works

An Impact Test Machine works on the principle of energy conservation. It quantifies the difference between the potential energy of a weight or pendulum before and after fracturing the specimen. This energy difference is the energy absorbed by the material on fracture, which denotes its toughness and capacity to endure sudden impact loads.

Specimen Preparation

A standard test specimen (notched or non-notched) is prepared as per test requirements (Charpy, Izod, or otherwise). The notch serves to concentrate the fracture.

Positioning the Specimen

The specimen is mounted in the machine – horizontally for Charpy or vertically for Izod – and securely clamped between anvils/supports.

Pendulum / Weight Raising

The pendulum hammer or drop weight is raised to a predetermined height, accumulating potential energy.

Drop the Weight

Release the hammer or pendulum, allowing it to strike the test specimen at high speed. The impact breaks or deforms the sample, simulating real-world shock or drop conditions to measure material toughness.

Take a Measure of the Absorbed Energy

The change in the height of the pendulum before and after shattering the specimen (or dial/digital gauge reading) indicates the energy absorbed during fracture.

Analyze Results

The value of energy absorbed is noted (in Joules) and employed to determine material toughness, ductile-brittle characteristics, or to compare the materials under equal circumstances.

Impact Testing Machine Uses

Impact testing machines are a key component in material toughness and resistance to impulsive forces in industries. They assist engineers and manufacturers in knowing how materials respond to dynamic loads so that they select appropriate materials for safe, high-performance, and durable products. The following are the key applications:

-

Material Selection and Quality Control

Impact testing guarantees that only materials with the needed toughness are chosen to be produced. It keeps manufacturers in line with consistent quality by checking each batch against standards in the industry. Testing routinely eliminates the use of brittle or faulty materials, limiting failure possibilities and providing reliability in applications where there is a chance of sudden shock.

-

Material Optimization

Through various compositions or treatment trials, impact testing assists engineers in maximizing materials for enhanced toughness and performance. Mechanical properties can be assessed to obtain desired properties through heat treatment, alloying, or processing techniques. This results in efficient, high-performance products designed for specific uses where impact strength is important for safety and functionality.

-

Structural Integrity

Impact testing assists in establishing whether structural elements are able to withstand abrupt loading conditions without disastrous failure. This is critical for building materials, pipes, and machinery components subjected to dynamic stresses. Valid test results guarantee that structural integrity is achieved, eliminating chances of accidents, breakdowns, or repair expenditures owing to brittle fracture.

-

Aircraft Components

Aerospace components are subjected to harsh conditions, such as collision due to debris, turbulence, and landing force. Testing of aircraft materials against impact ensures compliance with stringent safety regulations, preservation of structural integrity at high velocity, and avoidance of brittle fracture at low temperatures. This ensures the safety of passengers, operational integrity, and compliance with international aviation standards.

-

Durability and Safety

Impact testing assesses how well a material can absorb energy without failing, which is directly related to product safety and longevity. To industries such as automotive, rail, and heavy equipment, it guarantees parts do not fail unexpectedly in crashes or impacts, protecting human life and minimizing expensive downtime or liability resulting from accidents.

-

New Material Evaluation

While designing new materials like composites, alloys, or polymers, impact testing becomes critical to researching their ability to absorb energy. It is used to compare performance with traditional materials, optimize composition, and test suitability for actual applications. This is what drives the development of products at a faster pace and innovates the manufacturing, aerospace, defense, and automotive industries.

-

Ensuring Toughness and Reliability

Impact testing confirms a product or material will function predictably under conditions of sudden impact throughout its life. This is particularly vital in safety-related industries such as construction, energy, and transport. Assurance from reliable results maintains confidence in the material's toughness, lowering the risk of unforeseen failure, accident, or costly warranty claims.

Top Impact Test Machine Manufacturer in India

Testronix is recognized as one of the top manufacturers of impact test machines in India. The company offers reliable and easy-to-use equipment designed to test the impact strength of materials such as plastics, films, and packaging products. Testronix machines help manufacturers ensure their products can withstand real-world handling and transportation. With a strong focus on accuracy, durability, and after-sales support, Testronix has become a trusted partner for quality testing across various industries.