What is Colorimeter?

A colorimeter assesses and quantifies the spectrums of light emitted by an object. It is intended to measure the color change between a production sample and a known standard. Colorimeter uses filters to isolate a specific wavelength of light that the colored species absorbs. Then the photodetector measures the light that has passed through the specimen to measure the concentration of the species using the Beer-Lambert Law.

Also read: What is a Colorimeter?

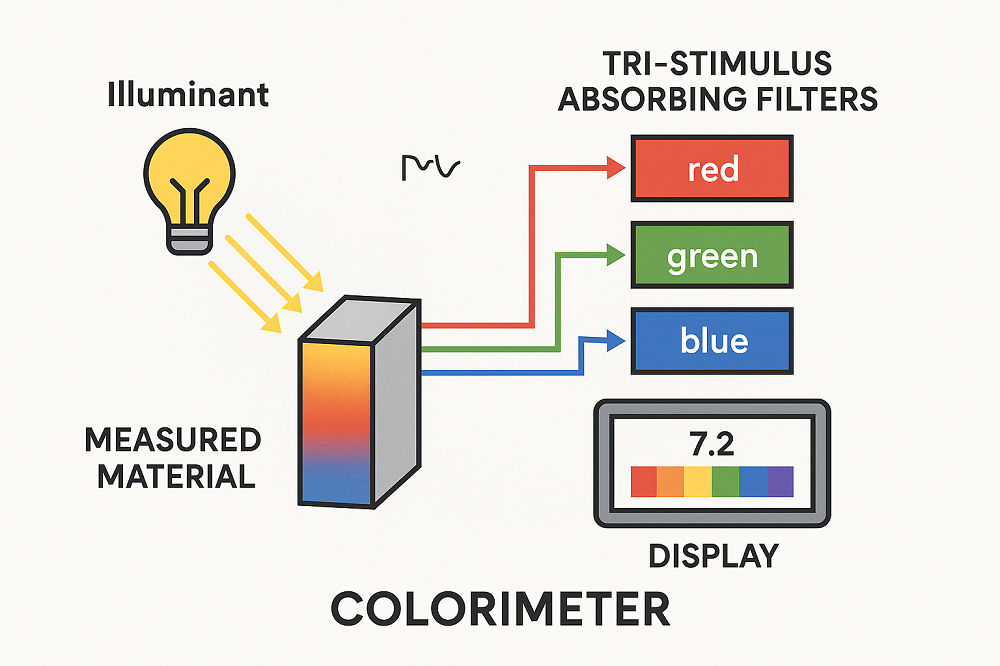

The major parts of a colorimeter include:

-

Illuminant - A particular light source illuminating the material being measured.

-

Tri-stimulus absorbing filters - Red, green, and blue (RGB) filters that measure the light emitted by the substance in tri-stimulus values, which simulate the response of the human eye to color.

-

Display - Presents the data to the user as a standard color scale and color variations.

How Does a Colorimeter Work?

A colorimeter uses a filtered beam of light that travels through a sample solution. The light is absorbed by the colored solute and the colorimeter measures the relative intensity of the light transmitted through the solution. A colorimeter functions using the Beer-Lambert law which states that the absorbance of light transmitted through a solution will vary directly with the concentration of the solute and the distance the light has travelled.

What is a Spectrophotometer

A spectrophotometer is an instrument that quantitatively measures the intensity of light absorbed by a substance at specific wavelengths.. The measurement is important in several industries such as pharmaceuticals, environmental monitoring, and quality control for the quantification of concentration, color verification, and compound identification.

How Does a Spectrophotometer Work?

A spectrophotometer functions by passing a beam of light through a sample to measure the light intensity of the sample. They are employed in the measurement process for color and are utilized during production to check for color precision.

An essential spectrophotometry system consists of a light source, digital readout, monochromator, wavelength chamber to convey a selected wavelength, collimator to direct a straight beam of light, photoelectric detector, and cuvette to hold a sample.

Colorimeter vs Spectrophotometer: What is the Difference

A colorimeter is an instrument that measures absorbance of light (at specific wavelengths) by using filters to identify the concentration. While a spectrophotometer is a more advanced measuring instrument that measures absorption or light transmission and returns data in a wider range of wavelengths. It is more informative and provides more color data and the ability to analyze complex color combinations and see metamerism.

Colorimeter Vs Spectrophotometer Difference

|

Feature |

Colorimeter |

Spectrophotometer |

|

Wavelength Range |

Restricted to around visible light (400-700 nm) |

Covers regions of UV, Visible, and IR (e.g., 190-1100 nm) |

|

Wavelength Selection |

Uses optical filters to choose narrow bands of visible light |

Separates and measures each specified wavelength using a prism or a grating (monochromator) |

|

Complexity & Cost |

Quite simple, budget-friendly, and easy to operate |

More difficult, expensive, and needed unique expertise |

|

Accuracy |

Perfect for daily, basic analysis |

High-accuracy, detailed measurements |

|

Versatility |

Not as versatile, mainly used just to compare the sample back to a standard |

Quite a versatile, enabling more complex color analysis and product development |

10 Differences Between Colorimeter and Spectrophotometer

The following are 10 key differences between a spectrophotometer and a colorimeter:

1. In spectrophotometers variable wavelengths over a potentially broad range of wavelengths are selected with a diffraction grating, whereas colorimeters will use broad-band, fixed wavelength color filters.

2. Spectrophotometers show full spectral data while colourimeters are based on a simple colour summary of perception.

3. Spectrophotometers are more accurate and precise because of their high spectral analysis capabilities, while colorimeters are less precise.

4. Spectrophotometers are also more versatile compared to colorimeters because they can analyze a greater range of samples and measurements (powders, solids, liquids).

5. Colorimeters are fairly cheap while spectrophotometers come at a premium due to their superior technology.

6. Colorimeters are less complex and easier to use with less technical about, while spectrophotometers are more complex and tend to need a professional to operate.

7. Colorimeters will require a larger sample volume for measurement than spectrophotometers.

8. Colorimeters are applied for simple color measurement and pass/fail quality control, while spectrophotometers are applied for sophisticated purposes such as color formulation, intricate spectral analysis and metamerism screening.

9. Hydrogen or deuterium lamps are commonly used in spectrophotometers for general UV/Vis operation, while a less complicated tungsten lamp is used by colorimeters for the visible region.

10. Colorimeters tend to be lighter and more portable for field use, although portable spectrophotometers exist for particular uses.

Colorimeter vs Spectrophotometer: Which is Better

The terms colorimeter and spectrophotometer are not better or worse than the other. It is more dependent upon the application, budget, and precision that is desired.

Colorimeters are less expensive, portable, and easier to work with for basic color matching and checking for consistency.

Spectrophotometers are more expensive, complex, and more specific, but more accurate. They also provide spectral information, plus the ability to measure difficult colors and detect metamerism. Spectrophotometers are superior in research and development purposes and in established color formulation systems where higher precision and accuracy are required.

Purchase Colorimeter and Spectrophotometer from Testronix Instruments

Testronix Instruments provides Colorimeters and Spectrophotometers that can fulfill your exact color measurement requirements as they are made of high-quality. Whether you want to perform a dependable Colorimeter to take precise color difference readings, or a versatile Spectrophotometer which provides spectral data, Testronix has credible and easy to use instruments that will deliver you reliable outcomes. A wonderful tool for industries such as pharmaceuticals, manufacturing, and quality control to ensure every product, you assure its accurate color every time. You can build a better testing process with a Tetrionix Instrument along with trust technology.