Learning about the behavior of polymer materials during the application of bending forces will aid in the long-term durability, functional performance, and safe use of these materials in their intended applications. The method outlined in the ASTM D790 standard allows for the determination of flexural properties of rigid and semi-rigid plastics and is widely accepted by manufacturers, design engineers, and quality assurance personnel. The performance of a plastic component under bending stress can be directly predicted by subjecting it to stress in real-life conditions to assess its performance.

What is ASTM D790 for Flexural Properties

The ASTM D790 testing standard provides a test to evaluate the flexural properties (bending) of reinforced and unreinforced plastics, high-modulus composites, and electrical insulation products. The testing format is a three-point (and sometimes four-point) setup where the test sample is supported by two points. While weight is applied directly on top of the sample at the center until failure occurs or the maximum strain which should not exceed 5%, is reached.

The need for this test method arises due to the fact that many types of engineering products are subjected to bending forces in addition to normal tensile or compressive loads. Therefore, both flexural strength and stiffness (sometimes referred to as "flexural modulus") are key design parameters for all products.

An example of this would be the plastic used in a car's dashboard, a beam on a building doing structural work, or an item of sports equipment, which all must resist a defined amount of bending before they can deform or fail under normal operation.

The results from ASTM D790 will aid engineers and designers in selecting the correct and most suitable materials for these types of applications, assist in maintaining quality control during production, and provide an opportunity to compare the performance of different materials and products.

What Does ASTM D790 Measure

The ASTM D790 test measures the flexural properties of rigid and semi-rigid plastics as well as electrical insulating materials. The results measured include flexural modulus (stiffness) and flexural strength when loaded in a bending mode. The standard test method is a three-point & four-point bend test to define how well a material can withstand loads.

Engineers and designers use this test for the selection of the materials for parts designed to take bending loads. Typical applications include Aerospace, Pharmaceutical, automotive, electronics, and construction.

What size specimen is ASTM D790?

The ASTM D790 standard outlines that the sample must be of a rectangular nature and may either be extruded, molded, or cut using plates/sheets of material. The ASTM D790 sample size is determined by the thickness of the base material and stipulated as per the D790 standard as the height of the specimen. The D790 standard specifies that, in the case of materials with a thickness greater than 3.2 mm, the width of the sheet material must be the same as its height and length.

The sheet material employed in the manufacture of the specimen must be no less than 3.2 mm thick and 1.6 mm thick; the width of the specimen will be 12.7 mm, and the length will be the product of the thickness and 16 of the length. Thus, THICKNESS x (16) will be the sum of the length. The smaller sheet material of less than 1.6 mm thickness will be 50.8 mm by 12.7 mm and 25.4 mm in dimension and support length, respectively.

ASTM D790 Flexural Test Method: Stepwise Procedure

The ASTM D790 flexural test is a test that incorporates the preparation of rectangular specimens, a universal testing machine equipped with a three-point bending test, measurement of the dimensions used, and a continuous load up to break or 5 percent strain, force, and deflection.

Here are the steps explained in detail:

-

Preparation of Rectangular Plastic Specimens

Standardized rectangular specimens of plastic are prepared by cutting or molding to 'normal' dimensions. The plastic specimens are conditioned at normal humidity and temperature levels before testing so that they have the same properties. It may eliminate any residual internal stress and obtain consistent and reproducible test results regarding their flexural performance.

-

Setting Up a Universal Testing Machine with a Three-Point Bending Fixture

A testing machine equipped with a three-point bending fixture, consisting of two supports and a center load nose, is used to install specimens. Alignment is carefully conducted in order to avoid twisting or slipping of the specimen that could affect the degree of accuracy.

-

Measuring Specimen Dimensions

Calipers or micrometers are utilized to accurately measure the thickness, length, and width of each specimen as it is cut. Calibrated measurements are critical in order to allow for accurate calculation of flexural strength, modulus and strain. Hence, it is used to establish compliance with the specifications set forth by ASTM D790 with respect to the specimen span-to-depth ratio and all other parameters used in the testing process.

-

Applied a Continuous Load with a Specified Rate

A test sample is loaded at its center with a steadily increasing amount of weight until it reaches its ultimate bending strength (when it breaks). There is a permanent deformation of 5% of the original specimen height to measure its mechanical response under bending stresses.

-

Measuring Force and Deflection to Calculate Flexural Strength and Modulus

During testing, the machine applies a force to the test sample and measures the deflection produced by that force. These two measurements are used in combination to determine the material's flexural strength, modulus, and strain. This allows for an understanding of the material's stiffness and resistance to bending as well as an estimate of how the material will perform structurally.

-

Adjusting Key Parameters like Span-to-Depth Ratio and Strain Rate

To standardize the adjustment of the strain rate based on specimen thickness, a support span is equal to sixteen times the specimen thickness (1/16). Specimens of varying thicknesses will have both the same loading and surface area, which means that the flexural test results will be consistent, repeatable, and reliable for all specimens when the parameters are controlled.

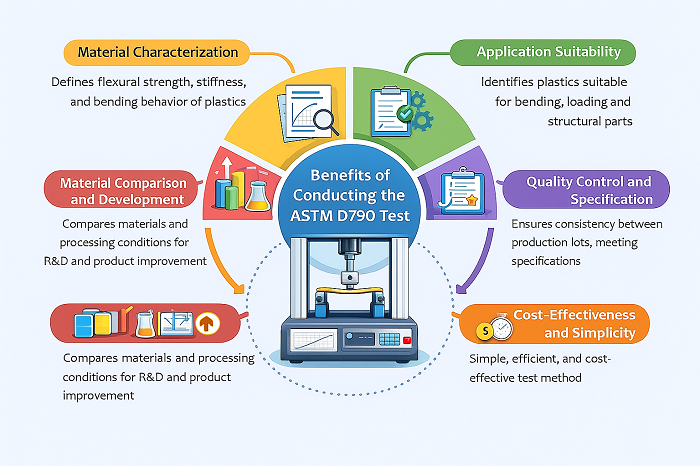

Benefits of Conducting the ASTM D790 Test

ASTM D790 consists of several benefits, such as material characterization, application suitability, quality control and specification, material comparison and development, cost-effectiveness, and simplicity.

Here are the benefits explained in detail:

Material Characterization

ASTM D790 defines specific information about a polymer's flexural strength, flexural stiffness, and behavior under bending loads. This information allows engineers to predict the mechanical stress the plastic will experience in day-to-day applications and thus the expected performance, durability, and point of failure of the plastic components. It forms a core part of mechanical property characterization.

Application Suitability

The flexural properties signify that a plastic can be used in applications that require bending, loading, or structural rigidity. Manufacturers can use this test to identify the most appropriate material(s) for their specific product needs by using them within their intended service life so that they do not break, bend, or deform under the load that is expected for long-term service life for panels, enclosures, housings, brackets, and structural parts.

Quality Control and Specification

The ASTM D790 test validates that the material meets the customer specification or the requirements of the applicable regulations. The test checks that there is consistency between produced lots through stiffness and flexural strength comparisons. This is used by manufacturers for the assurance of material reliability, maintenance of product quality, and rapid identification of possible defects or processing issues before either production or shipment.

Material Comparison and Development

The test will allow comparing the plastics of various formulations, fillers, reinforcements, or the processing conditions directly. The test assists in research and development since it demonstrates the impact of the changes that may influence the performance of bending. This assists the engineer to optimize the polymer blend, increase the grades of materials, and produce a variety of products that are stronger, stiffer, or more durable, which are applicable in certain applications.

Cost-Effectiveness and Simplicity

ASTM D790 is a simple, efficient test with minimal sample preparation and utilizing commonly available equipment. This simplicity helps reduce testing time and cost while delivering highly useful mechanical data. Since the test method is standardized, the test results are reliable, reproducible, and widely accepted across industries; therefore, decisions and material selections can be made more smoothly.

Conclusion

Flexural strength, flexural modulus, and flexural strain are some of the useful data adopted by manufacturers in assessing the properties of plastic materials. They apply mainly in the packaging, consumer goods, automotive, and engineering plastic markets. The analysis of such properties enables the manufacturers to make the right choice of materials, conduct quality control, improve the designs, and meet industry demands.

A UTM testing machine is the most effective way to assess a product's quality and ensure compliance with the ASTM D790 standard. Investing in a reliable tensile testing setup and selecting the right universal testing machine manufacturer is a smart move toward achieving long-term success.