The evaluation of materials via impact testing is critical to material science and engineering. Testing materials for their ability to resist sudden or impact loads without damage is essential for creating safe and dependable products. The behavior of many materials under impact loading is frequently different than their behavior under gradual loading. It is important to perform impact tests when designing products for the automotive, aerospace, construction, and manufacturing industries.

What is Impact Testing?

In impact testing, the capacity of a material to withstand sudden, high-energy forces (shock loading) is measured by quantifying the energy absorbed by the material prior to fracturing. The test demonstrates the difference between toughness and brittleness. This measurement usually exposes the samples such as metals, plastics and composite materials, to a cycle of rapid-impact tests on testing instruments like the Charpy and Izod testers.

Manufacturers and engineers typically use Charpy Izod Impact Tester to accurately measure the energy absorption & impact resistance of a material. With this measurement, the endurance of products is determined before it is shipped to the end customers and ensures product safety.

Principle Behind Impact Testing

Impact testing works on the principle of energy conservation. This is a straightforward concept that measures the amount of energy absorbed by a specimen when subjected to a high-speed impact force.

The amount of energy absorbed shows how much toughness the material has and how resistant it is to brittle fracture.

Impact testing is performed on metallic materials, polymeric materials, composite materials, and ceramic materials to verify the ability of those materials to perform within acceptable limits when subjected to sudden stress or load application and to verify that they comply with the safety and operational requirements.

Types of Impact Testing

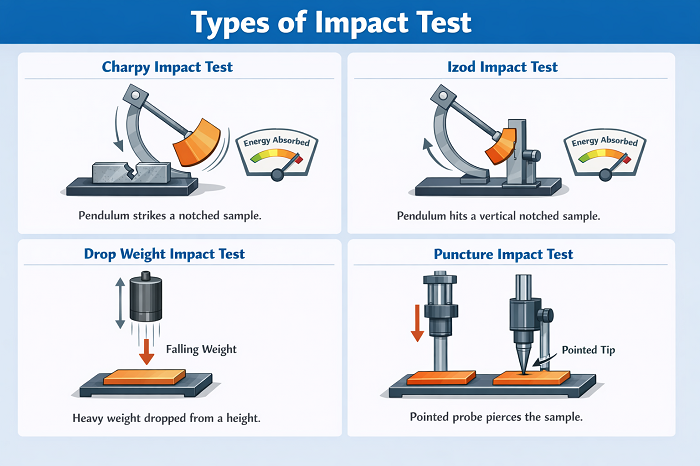

Impact testing comes in various forms depending on the type of force applied and the specimen design. Here are the most common types of impact tests explained in detail:

-

Charpy impact testing

Charpy impact testing measures the toughness of the material and its breaking. A swinging pendulum blows upon a notched sample and the energy absorbed by the sample is measured. The test can be used to indicate whether a material is ductile or brittle, and this can be used to predict the performance of the material when it is subjected to sudden impacts or when it is exposed to cold temperatures.

-

Izod impact testing

The Izod impact test measures how well a material, especially plastic, can resist sudden impact. A notched sample fixed at one end is struck by a swinging pendulum. The amount of energy consumed during the fracture of the test sample determines the toughness of the plastic and its reaction to cracking.

-

Drop weight impact testing.

A drop weight impact test checks how strong a material is when hit suddenly. A certain weight is dropped over the sample at a fixed height. The test gives the amount of impact the material can sustain before breaking, and the information is used by industries to select safe and tough materials under the impact of real-life conditions.

-

Puncture impact testing

Puncture impact testing is a test that determines the resistance of a material to being pierced by a sharp object. The sample is struck with a drop weight or pendulum with a point tool. The test demonstrates the toughness of the material and its failure, which assists in comparing plastics, packaging, and composite materials to actual handling and transport forces.

Testing Standards for Impact Testing

Impact Testing Standards are essential for performing Charpy (ISO 179, ASTM D6110) and Izod (ISO 180, ASTM D256) impact tests. Impact testing of the metals is done with the ISO standard (ISO 148-1) or the ASTM standard (ASTM E23) which specifies the required test temperature, sample preparation, and equipment conditions as part of testing the performance of the material under impact loading.

-

ISO 179-1: Non-instrumented Charpy test for plastics.

-

ASTM D6110: Charpy Impact Resistance of Notched Specimens of Plastics.

-

ISO 180: Izod impact strength for plastics.

-

ASTM D256: Izod Pendulum Impact Resistance of Plastics.

-

ASTM E23 / ISO 148-1: Governs impact testing for metals.

-

ASTM A370 / ASTM E208: Standards for impact testing steel materials.

-

ISO 13802: Standards for verifying pendulum impact testing machines.

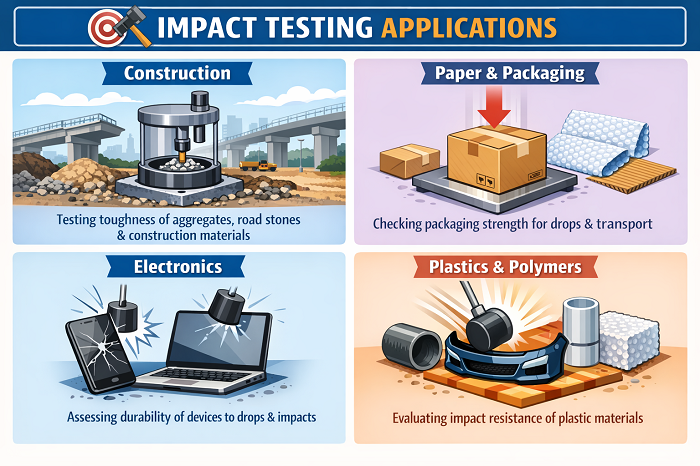

Applications of Impact Testing

Impact testing is a test method that is applied to assess materials with regard to toughness and energy absorption during an impact (or sudden force) to offer products in the automotive, aerospace, construction, and electrical/electronic industries with safety, durability, and quality. The applications will be as follows:

Automotive & Aerospace

The automotive and aeronautical sectors use impact testing to assess crash resistance and sudden impact performance in materials and components. Impact tests can be used to assess engines and other parts for resistance to impact and to inspect aircraft parts for performance in low temperatures.

Construction

Impact tests in construction help to determine the toughness of aggregates and construction materials. IS: 2386 tests help make sure that road stones and construction materials can withstand sudden loads, shocks, and vibrations, thus increasing the safety and durability of roads, bridges, and buildings.

Paper & Packaging

The impact test in packaging technology will make sure that packaging materials have the capability to protect a product during handling, storage, and transportation. Tests will show if packaging boxes, corrugated boards, and protective packaging layers can resist shock and prevent damage when they undergo drops and other possible transportation damage.

Electronics

In electronics, impact tests assess the resistance of screens, casings, and packaging to accidental drops and shocks. Impact tests enable the designs of smartphones, laptops, and other devices to become stronger and less prone to damage from everyday usage and shocks.

Plastics & Polymers

Impact testing in plastics and polymers relates to resistance to sudden loads. The technique is used on pipes, autos, foams, and elastomers to assess their capacity to withstand energy without cracking, failing, or deforming.

Conclusion

Impact testing is important in the modern-day material science field, as it may give viable data on how the material will react to a sudden or shock load. There are many types of impact testing applied by engineers, and they need to adhere to the international requirements when choosing the most appropriate method of testing.

It ensures that materials are safe, reliable, and will perform as expected under a variety of circumstances. By performing laboratory tests on different materials, including metals and polymers, their engineers gain insight into a material's expected real-world performance and therefore subsequently design their materials to help avoid material failures.