The physical property of liquids that demonstrates how readily a liquid will flow is known as liquid viscosity. The pharmaceutical, petroleum, food processing, chemical, and paint industries are some of those that rely on the use of viscosity measurements to determine the quality and performance of their products.

For this purpose, a viscometer is used to measure the viscometric characteristic of a fluid flow in a precise and accurate way. But how do viscometers work, and what types are available for different industries? This article will offer a thorough overview of the viscometer, encompassing its complete features and the diverse uses it can serve.

What is Viscometer?

Viscometers are devices that quantify the viscosity, or internal resistance to the flow or deformation of a liquid, produced by an external force. Rheometers measure the variable viscosity of a sample by determining its viscosity near the point of failure. For a viscometer measurement, the viscosity will remain constant, and the viscometer only measures the viscosity at one particular flow condition and no other condition. A viscometer can be used to determine the "thickness" or "thinness" of a liquid by calculating its resistance to movement.

Viscometer Diagram Explained

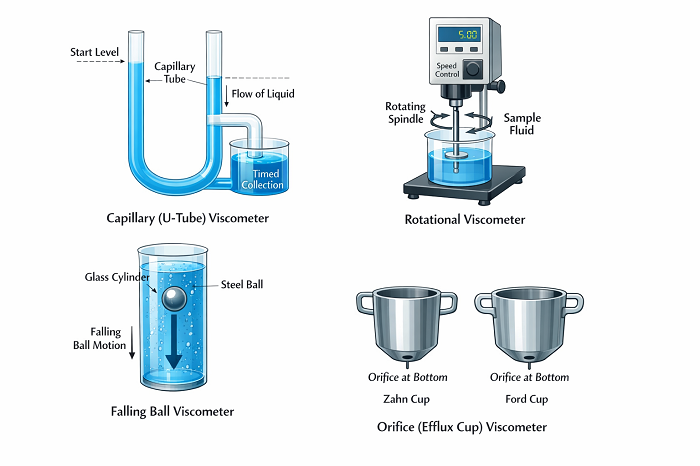

A viscometer is a scientific instrument to measure the viscosity which is the internal resistance to flow of a fluid. Different diagrams are used to explain the various mechanisms by which these devices operate.

-

Capillary (U-Tube) Viscometer Diagram: This is an example of a U-shaped glass viscometer which is commonly used to measure viscosity.

-

Rotational Viscometer Diagram: The Brookfield viscometer has a spindle that is rotated at a uniform speed and submerged in a sample.

-

Falling Ball Viscometer Diagram: A vertical or near-vertical cylinder filled with a liquid is an example of Stokes’ Law.

-

Orifice (Efflux Cup) Viscometer Diagram: Zahn and Ford are two examples of common paint industry cups and are typically represented in simplified cup designs.

What is the Working Principle of Viscometer?

A viscometer operates on the principle of assessing the reaction of a fluid to a force. It measures the resistance of a fluid to flow (viscosity) when forces are applied, which can occur through methods such as using a rotating spindle, a ball bearing weight dropping through the fluid, or applying gravity to determine the flow speed of a liquid through a capillary.

Different Types of Viscometers

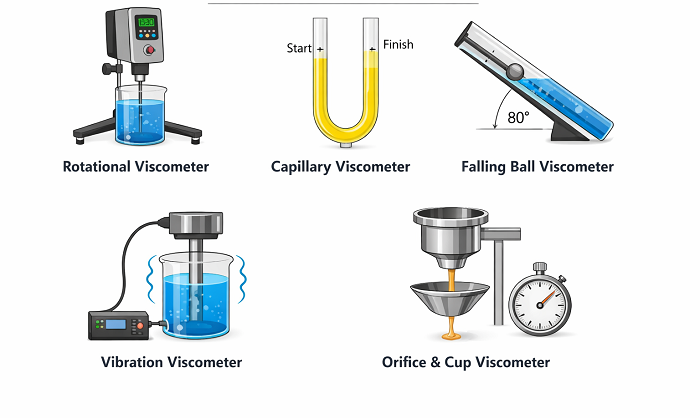

The different types of viscometers are rotational viscometers, capillary viscometers, falling ball viscometers, vibration viscometers, and orifice & cup viscometers.

-

Rotational Viscometers

By inserting a rotating spindle into the test fluid, viscosity measuring devices determine how much force is needed to maintain a constant speed. The viscosity of a fluid is indicated by the amount of internal shear resistance it possesses. Unlike methods based on gravitation, rotational viscometers provide a true value of the viscosity of a fluid based on the internal shear stress generated within the fluid.

-

Capillary Viscometers

Tube viscometers, also known as U-tube viscometers, are some of the most frequently utilized devices for measuring the viscosity of Newtonian fluids. They are glass devices that allow the user to measure the speed of a fluid flowing through a thin tube by using gravity or suction.

The viscosity of a Newtonian fluid can be determined by timing the time taken for a specified volume of fluid to pass through a small tube from the first to the second mark. The time taken is then multiplied by the viscometer calibration factor to give the viscosity value in cSt.

-

Falling Ball Viscometers

These instruments measure a fluid's viscosity by measuring the time it takes for a ball to travel through the fluid. Stokes' Law establishes the relationship between a liquid's viscosity and a ball's terminal velocity. Hoeppler’s principle states that most of these instruments are used at an angle of 80 degrees relative to the vertical axis. Additionally, these types of devices use balls of different sizes to measure viscosities ranging from 0.5 mPa·s to 70,000 mPa·s.

-

Vibration Viscometers

This equipment generates shear waves within a liquid and quantifies how swiftly the waves dissipate. The sensor consists of a steel cylinder, which can vibrate at its own "natural frequency." Once the sensor is vibrating, the amount of kinetic energy absorbed can then be related to the fluid's viscosity.

-

Orifice & Cup viscometers

This type of tool is simple, consisting of two main parts—a container with one or more holes and a catch basin. The drainage time is then used to measure viscosity. Paint and coating companies typically use these devices for quick checks of viscosity by using the timing method based on drainage times. However, their accuracy is not as high as other methods due to energy losses at the hole location and uneven pressure which can lead to measurement errors. They serve as useful parts in making sure that products are of good quality, as long as the required measurements are not critical.

How Does a Viscometer Work?

Viscometer works on the following steps, such as sample preparation, immersion of the measuring element, application of motion or force, measurement of resistance, and viscosity calculation & display. Here are the steps described in detail:

-

Sample Preparation

The liquid sample is placed in the container of the viscometer and is kept stable at a temperature that is controlled. This allows for the most accurate viscosity measurement because temperature has a direct impact on how thick (viscous) a liquid is (as it relates to the flow behavior of the liquid while being tested).

-

Immersion of Measuring Element

By introducing a measuring element such as a spindle, sphere, or narrow capillary tube into a liquid sample, the relation between the amount of resistance experienced as it moves through the fluid and the viscosity of that liquid can be measured.

-

Applied motion or force

The viscometer uses motion as part of an experiment by either rotating a spindle, dropping a ball, or letting a liquid flow downwards due to gravity. The applied motion exerts a force on the liquid, allowing it to move while also producing internal friction which corresponds to the liquid's viscosity.

-

Measurement of Resistance

Sensors gather data about the torque, speed, or duration of the movement. The amount of resistance recorded is proportional to how thick the material is. The values gathered allow a viscosity calculation to be made.

-

Viscosity calculation & display

Viscosity values are calculated based on the measured resistance by means of a mathematical formula. Each time viscosity is measured, the result will be presented in the same fashion as the other viscosity readings that were recorded. Once finished, digital viscosity values will be presented or physically displayed for analysis.

Primary Uses of Viscometer

Viscometers are quality control tools that several industries use in their own different ways to maintain product quality and performance. Here are the uses of the viscometer described in detail:

Oil and Lubrication Testing

The Oil & Gas industry uses viscometers for the measurement of drilling and well fluids and the viscosity of crude oil. The information obtained from these measurements is used to help ensure that extraction and processing occur smoothly. Viscosity is considered the most important property of lubricants because it has a greater impact on their performance than any other property.

Food and Beverage Processing

Food scientists consider the viscosity of a product to be crucial in shaping its texture, mouthfeel, and how it flows, i.e., through the filling or dispensing process. Therefore, this quality control factor plays a significant role in designing a food manufacturing process and in determining how a food product will be stirred, mixed, pumped, and packaged once it is produced.

Pharmaceutical and cosmetics formulation

The viscosity of inks, paints, and coatings can significantly influence their ability to be sprayed, level out on a surface, and adhere to that surface. The KU-3 Viscometer developed by AMETEK Brookfield is the most comprehensive instrument available today for measuring paint viscosity. The KU-3 measures paint viscosity in Krebs units, grams, and centipoise as defined by the ASTM D562 specification.

Paints, coatings, and adhesives

The viscosity of any liquid has a large impact on how well the paint or coating will level, spray, and adhere to surfaces. By using the KU-3 Viscometer made by AMETEK Brookfield, you can measure paint viscosity more accurately than any other product on the market today. This instrument provides measurements for paint viscosity in Krebs Units, grams, and centipoise based on ASTM D562 standards.

Conclusion

A viscometer is needed to measure fluid viscosity to maintain uniform quality during the different stages of production in an industry. This will enable one to better understand the working principle of a viscometer, the kind of viscometers available and the areas they can be used in your production line. This information will enable you to have a more controlled manufacturing process, maintain consistency in the quality, and improve the performance of your product.