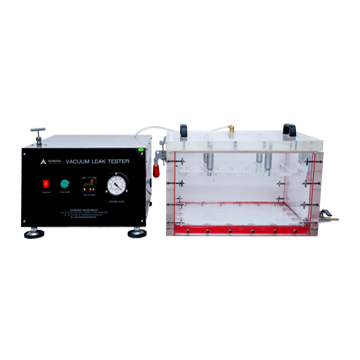

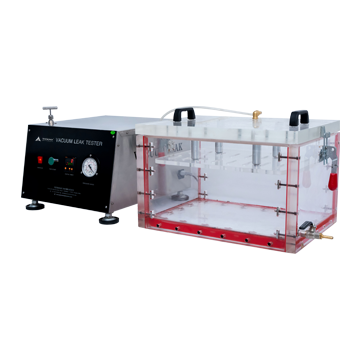

The Vacuum Leak Tester panorama is the most unique model as it has various applications. It Is also known as a bubble emission based model wherein the user can test vacuum leakage for bottles, pouches packets and other containers. This instrument is very helpful in detecting leaks.

The compressor/vacuum pump is a built in feature which helps in creating vacuum inside the chamber of the instrument. The vacuum pump is successful in creating upto 600hg of negative pressure. The chamber body is made of plexi-glass which helps in ensuring 100% insulation.

This instrument helps in detecting any sorts of leaks in a variety of products manufactured by industry specialists in the packaging domain.

The Vacuum Leak Tester offers high quality and precision. It has state-of-the-art technology to measure and detect any leakage in the specimen. The instrument is simple and easy to operate.

The Bubble Emission leak test method is designed for air filled samples. During the test if the user is able to observe air bubbles then the package is compromised/ faulty. The bubble emission indicates and can easily help the user in detecting the leaking point of the sample.Out leak integrity tester complies with the various test standards such as ASTM D3078-02, ASTM D6653, ASTM F 2338, ASTM D5094, ASTM 4991

The following samples can be successfully tested on this instrument:

1. LDPE & HDPE Bottles

2. PET Bottles

3. Air filled pouches

4. Packets & containers

Claim FREE copy of our latest Product Catalog.

Tell us where should we send your copy?

Tell Us What Product You are Interested In?