With the risk of exposure to dangerous fumes, vapors, and chemicals in contemporary laboratories being a major threat to scientists and engineers, proper ventilation is necessary to prevent damage to health, safety, and experimental purity. This is where a fume hood is important.

A fume hood is a ventilated cabinet used to restrict exposure to harmful airborne impurities by safely removing them from the user and purifying or evacuating them from the laboratory. As a first line of defense, fume hoods contribute to providing a safer working environment, minimizing contamination hazards, and meeting safety standards in any laboratory.

What is a Fume Hood?

A fume hood is a ventilated enclosure that safely removes harmful fumes, vapors, and dust during chemical experiments or processes. It is an essential device for the safety of laboratory personnel from chemical hazards by not allowing the contaminants to be released into the lab atmosphere.

Fume hoods are essential for laboratory exhaust systems and are the most common method of local ventilation. A well-maintained fume hood or lab hood offers essential protection when handling volatile and dangerous chemicals.

Regular inspection and maintenance of a fume hood or lab hood cannot be overemphasized, as it ensures maximum performance and worker safety. A properly functioning fume hood is critical to any laboratory setting to effectively handle risks.

Fume Hood Working Principle

The fume hood principle is based on negative pressure and directional airflow. By maintaining lower air pressure inside the hood compared to the surrounding environment, it ensures a consistent inward flow of air through the front opening, effectively containing and exhausting hazardous fumes.

Key Concepts that Support the Fume Hood Principle:

-

Negative Pressure: Ensures that air always flows into the hood, not out of it, thus containing harmful substances.

-

Laminar Airflow (Optional): In some fume hoods, airflow is designed to be smooth (laminar) to avoid turbulence that can lead to leakage.

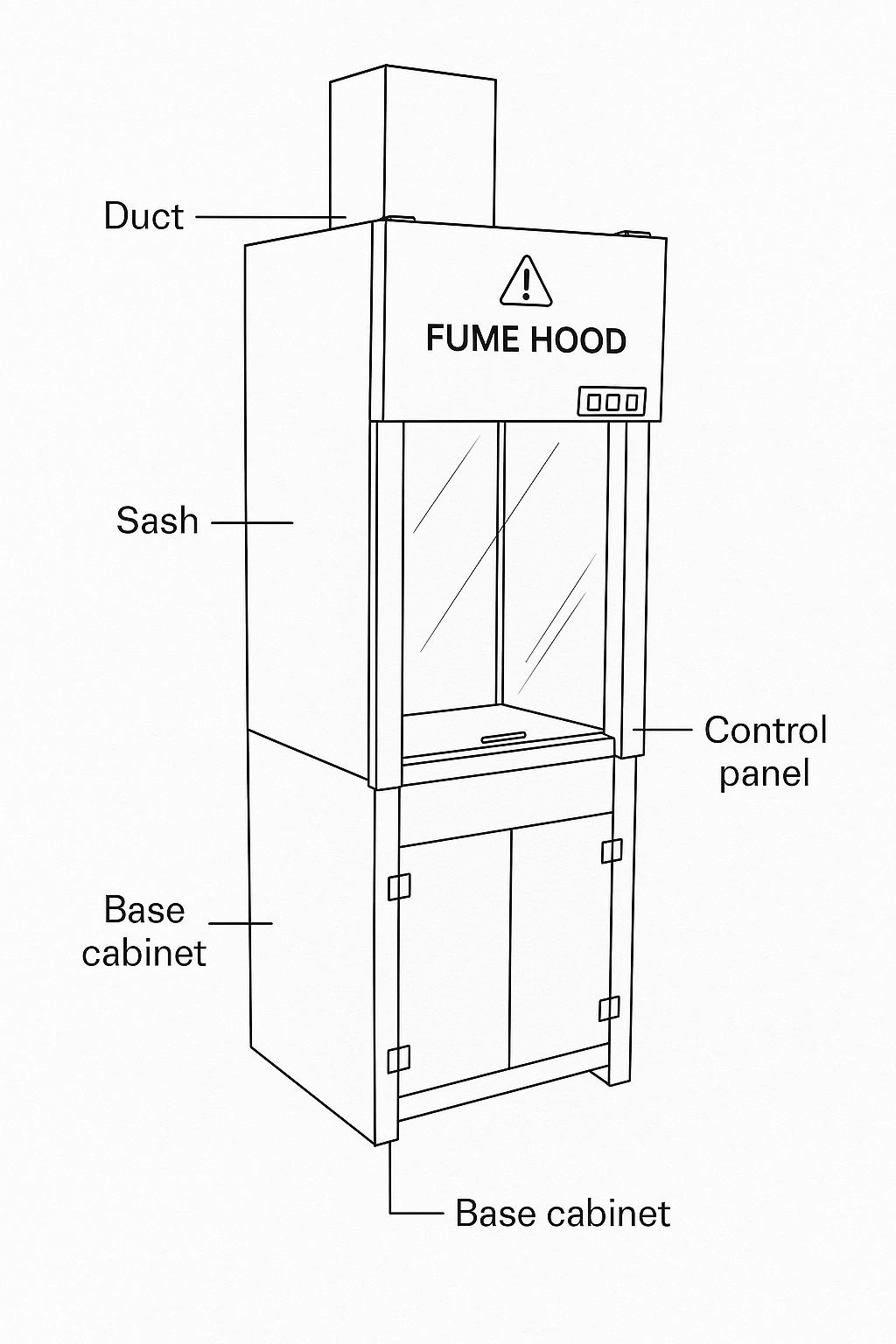

Laboratory Fume Hood Diagram

A fume hood diagram includes key components such as a ventilated enclosure, work surface, sash, and exhaust duct. These essential parts work together to effectively remove harmful fumes or gases, ensuring optimal performance and enhanced workplace safety. Here is a more comprehensive description of what comprises a fume hood and its respective roles:

-

Enclosure: The fume hood itself is a big box, usually metal or some other hard material, that contains the work area.

-

Face (Hood Opening): It is the space where the sash is, giving access to the work surface.

-

Sash: A removable, transparent piece of panel (usually glass) that modulates airflow into the hood. It serves as a protective barrier and can be raised or lowered to regulate the face velocity.

-

Work Surface: The surface on which laboratory work is performed, usually constructed of tough materials such as stainless steel.

-

Baffles: Adjustable partitions or slots along the back wall that assist in keeping an even airflow across the face of the hood, allowing effective fume capture.

-

Exhaust Duct: A closed vent pipe that transports exhausted air from the hood into the outside air or a filtering system.

-

Exhaust Fan (or Air Pump): The mechanical equipment that draws air into the hood and through the exhaust duct.

-

System Airflow Monitor and Hood Face Velocity Monitor: Devices that measure the airflow through the hood and its face velocity, to ensure proper function and safety.

-

Bypass Grill: A grill or opening through which air may bypass the sash when it is closed, to ensure constant face velocity.

How Laboratory Fume Hood Works?

A fume hood is a ventilated cabin that works by removing harmful fumes and gases by sucking them into the hood and expelling them to the exterior or via a filtration system. The process entails the generation of negative pressure within the hood, causing the dirty air to get trapped and eliminated, thus not allowing it to escape into the laboratory.

Step 1: Air Intake Through Sash Opening

The fume hood starts by pulling room air into its front via the open sash (glass window). This establishes directional airflow towards the interior of the hood.

Purpose:

To create a barrier for the user and the possible toxic material within the hood.

Controlled factors:

-

Sash height (the lower the sash, the better the containment)

-

Air velocity (usually 80–120 feet per minute)

Step 2: Creation of Negative Pressure Zone

A blower or exhaust fan generates a negative pressure within the hood, which constantly draws air in.

-

Purpose:

To keep dangerous vapors or particles from permeating into the laboratory environment. This pressure gradient traps contaminants in the fume hood.

Step 3: Airflow Direction and Baffle Operation

The air gets into the hood and passes smoothly over the work area, helped by adjustable baffles in the rear of the hood.

Purpose:

-

To avoid stagnant or "dead" air areas

-

To propel contaminants towards the exhaust effectively

-

To provide laminar (non-turbulent) flow for the best capture of fumes.

Step 4: Contaminant Capture and Removal

As the air passes through the fume hood, vapors, gases, and particles that are produced due to chemical reactions or processes are captured. The dirty air is sucked through an exhaust system of ducts and released outdoors safely.

Step 5: Continuous Control and Monitoring

A control panel or airflow monitor monitors the speed and flow rate of air. When airflow becomes sub-safe, an alarm sounds.

-

Purpose:

To make sure that the hood is working correctly and the user is always protected.

Step 6: Exhaust and Ventilation

The last step is the elimination of tainted air through the exhaust system or filtration. The fan keeps on sucking the air out, keeping a constant stream.

Purpose:

- To complete the cycle of air exchange

-

To keep toxic substances from building up

-

To ensure safety compliance (e.g., OSHA, ANSI, ASHRAE)

Types of Laboratory Fume Hoods

-

Ducted Fume Hood

A ducted fume hood exhausts contaminated air through ducts to the outdoor environment through negative pressure and continuous airflow for safe handling of hazardous substances in chemical reactions or processes in the laboratory.

-

Ductless Fume Hood

A ductless fume hood employs internal filter systems like activated carbon or HEPA filters to clean out contaminated air and return it to the laboratory, thus appropriate for occasional use with known, low-risk chemicals in flexible laboratory arrangements.

-

Walk-in Fume Hood

A walk-in fume hood is a floor-sitting enclosure used to deal with large equipment or large-scale reactions. It works on the same basis as ducted hoods but provides users with the facility to step inside or access tall experimental setups without any danger.

-

Bench-top fume Hood

A bench-top fume hood is a small hood on a laboratory bench, perfect for limited, routine experiments. It is used as a regular fume hood, either ducted or ductless, based on the ventilation system and planned chemical use.

-

Canopy Fume Hood

A canopy fume hood is installed over heat- or steam-producing equipment and exhausts warm air or light fumes by upward ventilation. It does not have frontal containment and is therefore acceptable for non-toxic or low-hazard operations such as cleaning or sterilizing glassware.

-

Auxiliary Air Fume Hood

An auxiliary air fume hood provides outside air to the hood directly to counteract the exhausted volume, which decreases HVAC load. It is safe while being energy-saving, and therefore it is applicable in high-usage laboratory environments where airflow management is an issue.

Applications: What is Fume Hood Used for

A fume hood is an essential safety instrument employed within laboratories to safeguard people, ensure clean air, and obey health and safety rules. Its uses cut across different scientific, industrial, and educational settings. The following is a descriptive illustration of the major uses:

-

Handling Hazardous Chemicals

Fume hoods are commonly used when working with volatile, flammable, or toxic chemicals, such as acids, solvents, and organic reagents. These substances can generate harmful vapors or fumes that pose a health risk. A fume hood contains these emissions and pulls them away from the breathing area, thereby minimizing the user's exposure.

-

Carrying Out Chemical Reactions

When undergoing chemical reactions, particularly those with heat, reagent mixing, or unknown results, fume hoods prevent splashes, fumes, or unexpected gas releases. Containment prevents the user and laboratory environment from exposure or explosions by accident.

-

Handling Carcinogenic or Mutagenic Compounds

Chemicals that may be carcinogenic or mutagenic must have rigorous containment procedures. Fume hoods prevent these toxic chemicals from spreading into the air, allowing laboratories to maintain compliance with workplace safety requirements and safeguard users against long-term exposure.

-

Heating and Evaporation Procedures

Fume hoods are perfect for the heating of flammable or volatile materials since heating can accelerate the emission of vapor. They are also useful during evaporation operations when solvent fumes are evolved, ensuring air quality and the safety of lab workers.

-

Transfer and Dilution of Chemicals

In the case of transfer, dilution, or mixing chemicals from one container to another, there are chances of spillage and vapour release. A fume hood provides for safe ventilation of any fumes produced during such activities, particularly with concentrated acids or bases.

-

Acid Digestion and Sample Preparation

In environmental, food, and forensic laboratories, digestion of samples with concentrated acids is routine. This produces heat and releases hazardous gases such as nitric oxide or sulfur dioxide. A fume hood is essential to safely vent these by-products.

Conclusion

A fume hood is a necessity for any environment that deals with dangerous, volatile, or unknown chemical reactions. From shielding scientists from inhaling poisonous gases to keeping a lid on explosions or providing a safe learning environment, the fume hood is a first line of defense supporting safety as well as scientific advancement.