Precision in today’s manufacturing and quality control systems cannot be compromised. The reliability and safety of a product require torque testing. Whether it is a bottle cap that you need to screw on or a car part that you need to assemble, it is critical to the whole process to have the right torque value. It is also here that torque testing comes in, since manufacturers can be keen to make sure that these fasteners, closures, and other components are within the set torque range, as it helps to counter mechanical leakage and other problems.

What is Torque Testing?

Torque testing is the measurement of the rotational force applied to screw some objects tight or loose (screw, bolt, cap, lid). The magnitude of this force is usually scaled in terms of Newton-meters (Nm), inch-pounds (in-lb), or even kilograms-force centimeters (kgf-cm).

Both application torque (the force that you would apply to tighten an object) and removal (breakaway) torque (the force that you would need to apply to loosen) are determined using torque testing.

Why Torque is Important in Manufacturing

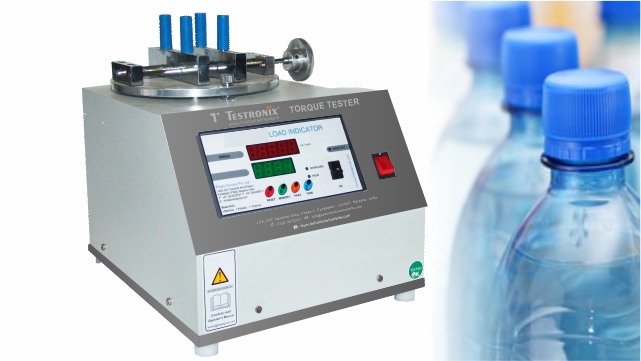

The use of torque testing in the manufacturing process is very valuable for ensuring that the components manufactured are both safe and functional. One area of application for torque testing is in the bottle industry. Torque testing for bottle caps ensures that sufficient force is applied to securely close the cap, thus providing child resistance.

However, torque testing for bottle caps must ensure that the force used in securing the cap does not cause breakage of the bottle itself (i.e., glass or PET (polyethylene terephthalate) materials).

Similarly, torque tests provide manufacturers with an indication of how their products will be experienced by consumers in the field. For instance, torque testing on bottles can determine the appropriate tightness or looseness of the cap.

When the caps are tight and consumers can hardly open them, such behavior is likely to cause frustration to the user and eventually lead to product failure. With loosely capped bottles, there is a possibility of the bottle losing its integrity through loss of pressure or contamination by the open cap.

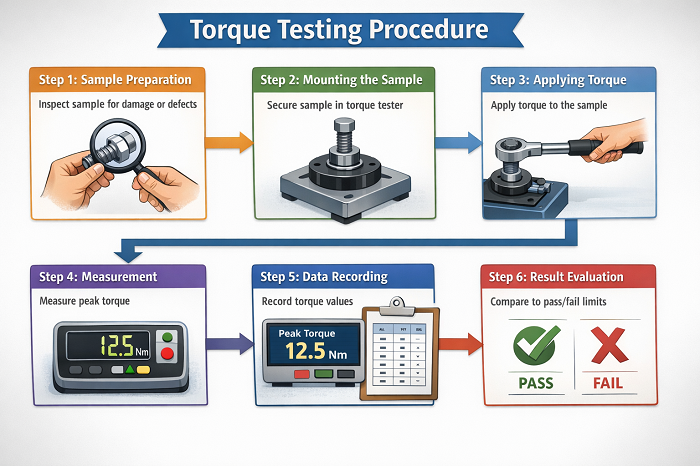

How Torque Testing Work? Step-wise Procedure

Torque testing is a procedure that involves a number of steps, including preparation of the sample, sample mounting, sample torque application, measurement, recording of the data, and evaluation of the outcomes. The following steps are outlined in detail:

Step 1: Sample Preparation

The testing specimen, whether it is a cap, a bolt, or a fastener, is chosen from the production. It is also inspected visually for surface damage, deformation, or other surface irregularities to ensure the results of the testing are accurate.

Step 2: Mounting the Sample

The test sample is carefully seated in the torque tester mounting base. This is done to ensure that it is not twisted, slippage or unbalanced force application is avoided, or incorrect torque values could result.

Step 3: Applying Torque

This torque can either be applied manually or using an automated system. Now, the rotational force is incremented until either tightening or loosening takes place at the desired testing condition.

Step 4: Measurement

When torque is applied, it measures the rotational force that is measured by a torque tester. The tester records the peak torque value exactly when the sample is tightened/loosened.

Step 5: Data Recording

The torque values measured are displayed on the digital display and recorded in the memory system. This allows quality documentation, traceability, auditing, and analysis to be performed.

Step 6: Result Evaluation

These torque values are then measured and compared to the acceptance limit standards. According to this comparison, the result is either pass or fail.

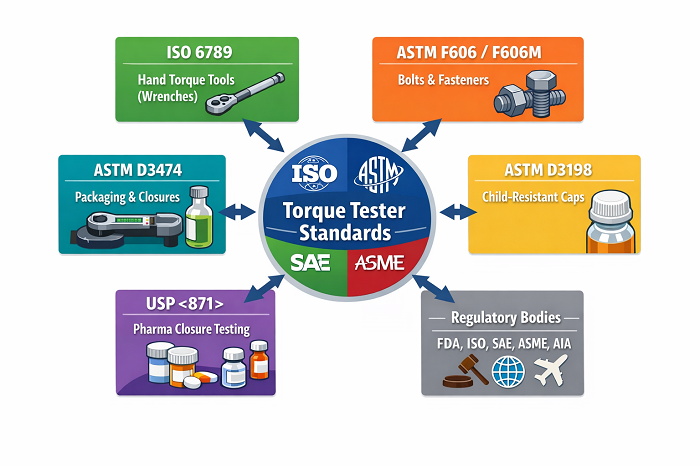

Torque Tester Standards

Torque tester standards should be tested for accuracy & consistency according to the standards outlined, such as ISO 6789 for hand tools & ASTM Standards (ASTM D3474 for packaging, ASTM F606 for bolts).

The main organizations that set torque test standards are ISO, ASTM, the Society of Automotive Engineers, and the American Society of Mechanical Engineers.

In addition, in the pharmaceutical industry, the USP <871> is often referenced.

-

ISO 6789: Defines requirements, test methods, and marking for hand torque tools (wrenches).

-

ASTM D3474: For calibration/use of torque meters in packaging (caps, closures).

-

ASTM F606/F606M: Describes mechanical properties of threaded fasteners including torque/tension.

-

ASTM D3198: Specifically for testing child-resistant closures.

-

USP <871>: Pharmaceutical standard for closure torque testing (e.g., bottle caps).

-

Regulatory Bodies: FDA, ISO, ASTM, SAE, ASME, and AIA set guidelines for different industries.

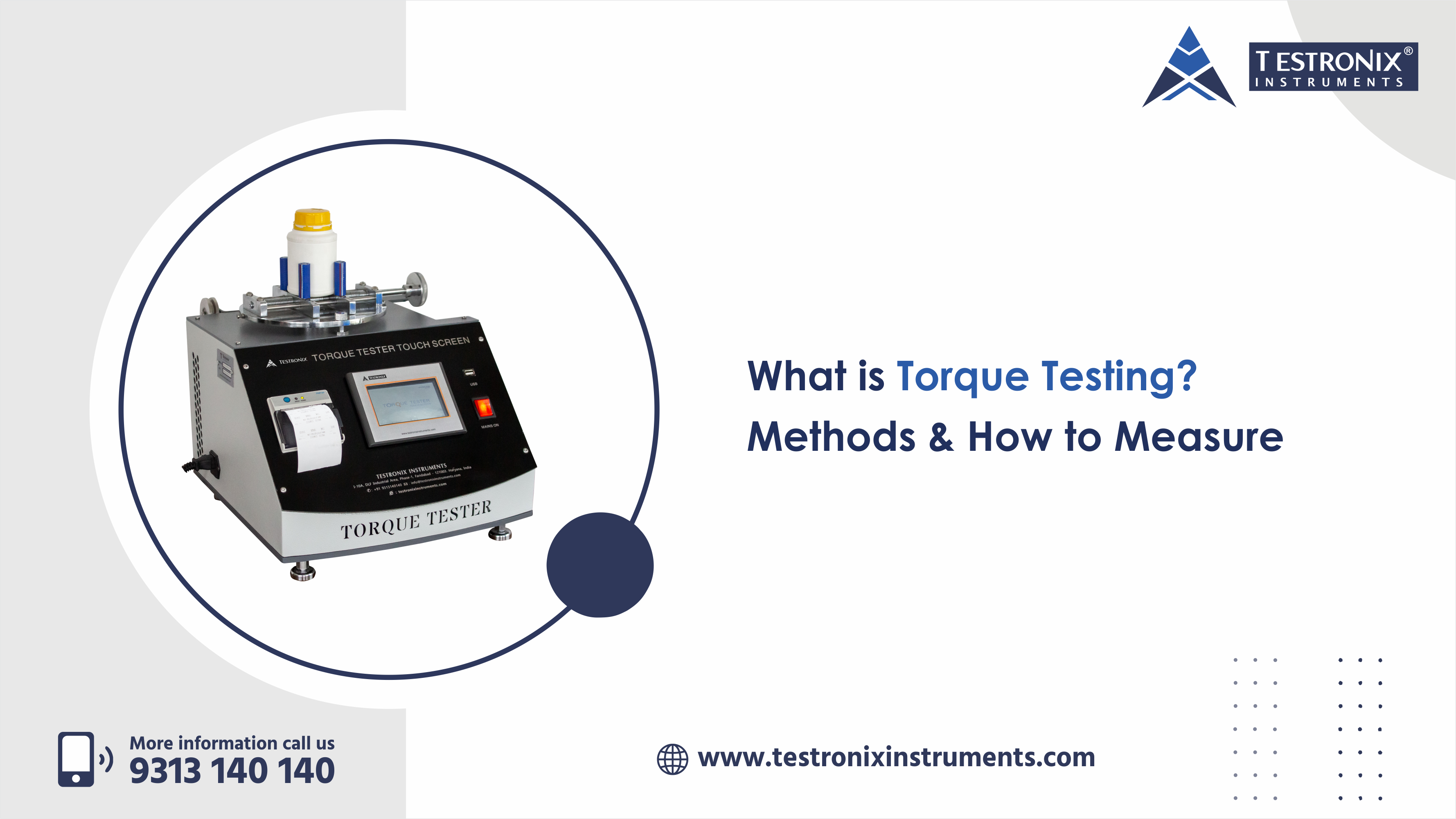

Torque Tester: Equipment to Measure Torque

The process of torque testing is defined as determining how much torque, or rotational force, will be necessary to turn an object or to check that it has been assembled correctly by meeting a predetermined torque specification.

All industrial sectors use the torque test for quality assurance, safety, and reliability of their products. Typically, these industrial sectors include manufacturing (assembling parts or machines), automotive (engine and transmission installation), aerospace (aircraft component assembly), and construction (building structure).

Testronix offers precision torque testers that measure the rotational force used in production by providing accurate values for industrial machinery. These torque test devices provide reliable measurements, store data, and are easy to operate due to their sensitive load cell sensors and digital readouts.

The Testronix Torque Tester enables companies to maintain precise and consistent torque levels, ensuring better overall product quality. It also helps manufacturers comply with ISO standards across various processes including packaging, automotive, and assembly, supporting consistency and reliability throughout production.

Conclusion

A quality control process, torque testing is a critical measure that guarantees product safety, functionality, and compliance in all industries. Torque testing provides manufacturers with a method of fixing the rotation or rotational force (also known as torque).

Torque testing helps manufacturers identify potential failures before they happen, improves stability and ensures that the quality of production remains consistent. The Testronix torque tester uses cutting-edge technology to help manufacturers get the right torque measurements. This means that fewer defective products are made, and better quality products are sent to market.