Climate test chambers are necessary lab equipment for automotive, electronics, aerospace, and pharmaceutical companies. They provide simulated environments like temperature, humidity, and pressure to test product durability and reliability. Selection of the chamber can be tricky as it relies on your unique testing requirements, product specifications, and cost factors.

In this article, you will get a step-by-step guide on the types of chambers out there and receive useful tips on how to make the best choice of a climate chamber. From understanding basic models to exploring advanced features like rapid cycling or combined stress testing, this guide will help you choose a chamber that fits both your technical needs and budget.

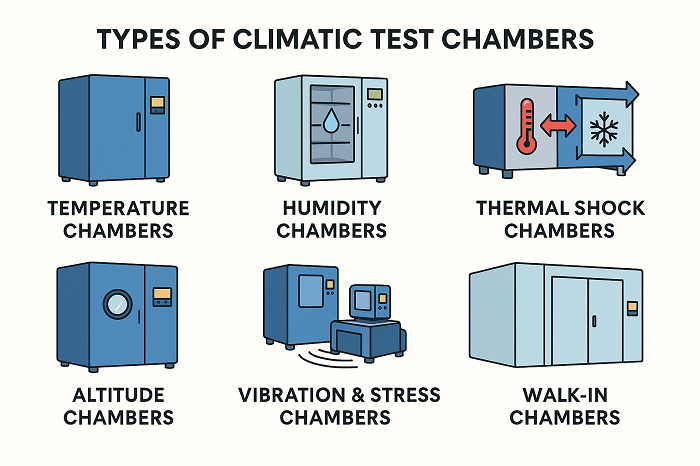

Types of Climatic Test Chambers

Climate test chambers come in various configurations to simulate different environmental conditions. They are tailored for specific testing needs such as temperature, humidity, or combined stress testing. The selection of the right type of climatic chamber is based on your industry, product design, and performance requirements.

Temperature Chambers

Temperature chambers are used to mimic harsh cold and hot environments. They assist in analyzing how products fare when exposed to different temperature ranges, with the aim of determining durability in the actual environment. Temperature chambers are applied across automotive, electronics, and aerospace industries where parts need to survive harsh weather conditions, making them a go-to option for thermal stability testing.

Humidity Chambers

Humidity chambers regulate moisture levels by controlling relative humidity and temperature. They are essential for testing materials sensitive to corrosion, warping, or microbial growth under moist environments. Industries like pharmaceuticals, textiles, and packaging use them to ensure long-term reliability and product performance when exposed to tropical or damp climatic conditions.

Thermal Shock Chambers

Thermal shock chambers mimic sudden temperature shifts through rapid switching between hot and cold conditions. They are employed to subject materials to expansion, contraction, and structural stability under extreme changes. This category is essential in aerospace, electronics, and defense, where products are required to withstand rapid thermal changes without compromising performance or safety.

Altitude Chambers

Altitude chambers simulate high-altitude conditions through pressure, temperature, and occasionally humidity modification. They are applied mainly in aerospace, military, and automotive industries to subject aircraft components, satellite components, and navigation devices to testing. Chambers ensure the effectiveness of products at varied altitudes where air density and pressure greatly affect functionality and safety.

Vibration and Stress Chambers

Vibration and stress chambers mix mechanical vibration with climatic conditions like temperature or humidity. They are meant to simulate actual conditions under which products experience both physical as well as environmental stress. Found in automotive, defense, and electronic industries, these chambers guarantee components can withstand transportation conditions, operational wear, and extreme environmental factors at the same time.

Walk-in Chambers

Walk-in chambers are large-scale test chambers employed for testing large products or batches of parts under controlled conditions. They provide flexibility to mimic temperature, humidity, and pressure conditions in a large setup. Aerospace, automotive, and consumer goods industries depend on walk-in chambers for large sample testing, prototype creation, and international quality standards compliance.

Environmental Test Chambers

Environmental test chambers are specialized enclosures that control conditions such as temperature, humidity, pressure, and even vibration to mimic different environmental stresses on a product. They enable manufacturers and researchers to determine a product's durability, functionality, and performance under actual conditions, allowing for potential failure identification, reliability enhancement, and compliance with regulations prior to market availability.

How to Choose the Right Climate Test Chamber

To select the suitable climate test chamber, you need to specify your test requirements, such as temperature and humidity ranges required, and the size and weight of test samples. Additionally, compare chamber specifications such as uniformity, temperature exchange rate, and data logging, where the quality of the build is high.

Here are 7 guidelines for choosing the right climate test chamber:

-

Define Testing Requirements

Clearly define the precise environmental conditions your products will be required to endure, e.g., temperature (min. and max.) and humidity conditions, and determine any applicable industry standards (e.g., ISO, ASTM, MIL-STD).

-

Consider Sample Size

The test specimen dimensions, shape, and weight are essential. Identify whether your product is a "live load," generating heat, as this will affect the chamber's power and performance required.

-

Assess Temperature and Humidity Performance

Select a chamber that will readily attain your target temperature and humidity levels. Recognize the distinction between single-stage chambers (e.g., 180°C to -40°C) and double-stage or cascade chambers for extremely low temperatures (e.g., -70°C).

-

Inspect Uniformity

Guarantee that the chamber ensures even temperature and humidity across the entire space, with adequate airflow. Observe the temperature exchange rate (speed of temperature change, e.g., in °C/min), as this is important for quick testing.

-

Check Programmability and Data Logging

Select chambers equipped with programmable controllers to facilitate complex test cycles and enable data logging. These features are essential for accurate record-keeping and thorough analysis, ensuring reliable results and informed decision-making during experiments or testing procedures.

-

Evaluate Quality and Maintenance

Ensure that the chamber is high quality, requires good maintenance, and has good support.

Invest in chambers from trustworthy manufacturers with a good reputation for quality and performance. Look for easily accessible components that make cleaning and maintenance easy, and verify that the manufacturer has good customer support and easily available spares.

-

Consider Operational Factors

Consider the footprint of the chamber and its integration into your plant, especially for larger sizes. Also, evaluate potential operational expenses, such as energy usage, and determine if special accessories or remote condensers are needed.

A climate test chamber is a long-term asset directly related to product quality and compliance. Knowing the categories of chambers and thoroughly comparing performance, size, standards, and expenses helps you choose the best chamber for your requirements. Choosing the right chamber guarantees consistent testing, improved product performance, and long-term return on investment for your organization.

When considering high-quality climate test chambers, Testronix Instruments stand out as a leading choice. With our advanced technology, precision performance, and reliability, we provide robust solutions that meet the rigorous demands of testing and product development.