Corrosion testing is of paramount significance in the determination of materials, coatings, and surface treatments in hostile environments. The most popular tests are copper accelerated acetic acid salt spray tests and neutral salt spray tests.

Although they are both salt spray tests, very different purposes, test conditions, and corrosion test intensities apply to them.

These differences should be known so that manufacturers, quality engineers, and researchers can select the appropriate methodology that can be used to determine durability, determine the life span of their products, and ensure that their products can meet the standards of the industry.

What is CASS Test?

A CASS test stands for Copper Accelerated Acetic Acid Salt Spray test. It is an aggressive corrosion resistance test for different coatings, particularly on aluminum alloys, nickel, and chromium. The mix of acetic acid and copper ions creates a salt spray environment that is much harsher than a typical salt spray test. The test is designed to replicate severe and aggressive environmental conditions that a product might face.

CASS test is commonly employed in investigating decorative chrome plating, anodized aluminum, and other protective surface finishes. The test is used to estimate the ability of the coating to survive long-term exposure to corrosive elements since the situation of CASS is far worse than that found in common salt spray tests. It provides insights into the product quality and coating performance.

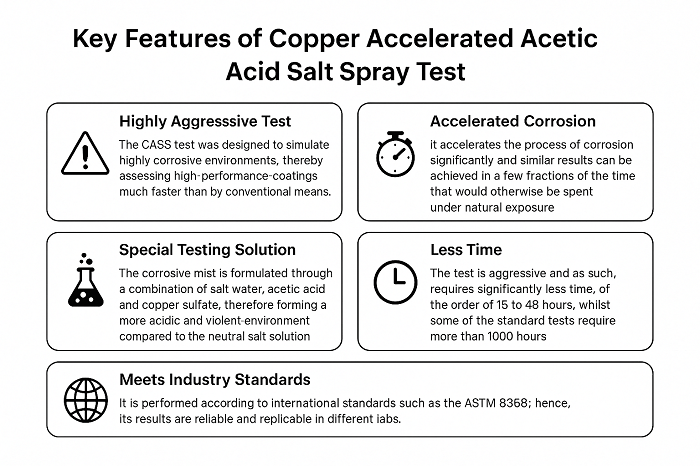

Key Features of Copper Accelerated Acetic Acid Salt Spray Test

The main features of the CASS test are that it is very aggressive, works at high temperatures, and uses a special corrosive solution to speed up the corrosion testing.

Key features:

-

Highly Aggressive Test: The CASS test was designed to simulate highly corrosive environments, thereby assessing high-performance coatings much faster than by conventional means.

-

Accelerated corrosion: It accelerates the process of corrosion significantly and similar results can be achieved in a few fractions of the time that would otherwise be spent under natural exposure.

-

Special testing solution: The corrosive mist is formulated through a combination of salt water, acetic acid and copper sulfate, therefore forming a more acidic and violent environment compared to the neutral salt solution used in the conventional salt spray tests.

-

Less time: The test is aggressive and as such, requires significantly less time, of the order of 16 to 48 hours, whilst some of the standard tests require more than 1000 hours.

-

Meets industry standards: It is performed according to international standards such as the ASTM B368; hence, its results are reliable and replicable in different labs.

What is NSS Test

The NSS test refers to neutral salt spray test which is an accelerated corrosion test method to evaluate the corrosion resistance of metallic materials and their coatings. It tests how well materials, like those with paint, electroplating, or galvanization layers, can resist corrosion. This examination is especially important in humid or marine environments. The NSS test is an internationally accepted quality control test widely used in a variety of industries, such as automotive, aerospace, and building construction.

The main objective of the NSS test is to determine the quality and resilience of the protective finishes when samples are exposed in a controlled laboratory to a corrosive environment at an accelerated rate. This accelerates the natural corrosion that would occur over much longer periods in a real-world environment and thus enables the comparison of various materials or coating processes in a rather short period of time.

Key Features of Neutral Salt Spray Test

The principal characteristics of the neutral salt spray test include a neutral pH, a fine mist using a 5% sodium chloride solution, and standardization to provide a repeatable method of corrosion resistance evaluation.

Key Features:

-

Neutral pH: The testing solution has a neutral pH, ranging from 6.5 to 7.2.

-

Salt mist: A fine mist of sodium chloride solution is continuously sprayed into a sealed chamber.

-

Standardized and reproducible: The NSS test is a simple, widely standardized methodology that yields results that are generally consistent and reproducible.

-

Material and coating evaluation: It is well adapted for the corrosion performance evaluation of metals, their alloys, and different coatings, such as zinc, nickel, and paint.

-

Quality control: Applied for quality control in the comparative analysis of corrosion resistance of products.

CASS Test vs NSS Test: The Difference

|

Parameter |

CASS |

NSS |

|

Purpose |

Evaluates highly corrosion-resistant and decorative coatings |

Tests typical corrosion resistance of metals and coatings |

|

Solution Used |

Salt solution + copper chloride + acetic acid |

Neutral 5% sodium chloride (NaCl) solution |

|

pH level |

Acidic (approx. 3.1–3.3) |

Neutral (approx. 6.5–7.2) |

|

Typical Applications |

Decorative chrome plating, anodized aluminum, and high-performance coatings |

Paint coatings, zinc plating, metals, and general protective layers |

|

Test Duration |

Shorter, because corrosion progresses rapidly |

Longer, as corrosion progresses at a normal rate |

|

Industry Standards |

Often follows ASTM B368 |

Follows ASTM B117 |

Applications of CASS Test and NSS Test

Applications of CASS (Copper Accelerated Acetic Acid Salt Spray) Test

-

Quality Control

The CASS test can be used by the manufacturers in quality control to spot the weaknesses in the materials, coating, or layers of plating used in the process; this may result in premature corrosion. They detect product defects at the early stages of the product life cycle to ensure that only high-performance products that are durable end up in the market, and this would reduce failures and subsequent warranty claims.

-

Acceptance of Specification

Corrosion resistance standards, which are required by clients, industries, or certifications, are tested through the copper accelerated acetic acid salt spray Test (CASS). The test confirms coatings and materials for their specification compliance before approval, allowing manufacturers to maintain consistency in their regulatory or customer-driven quality expectations.

-

Mock Service Reviews

This test simulates aggressive, salt-laden environments for the prediction of real-world performance in a shorter time period. This accelerated corrosion exposure assists industries in understanding how products will behave in harsh conditions and aids in effective decision-making related to material selection, coating improvements, and product reliability.

-

Research and Development

Copper accelerated acetic acid salt spray testing is employed in R&D teams to assess the performance of prototypes, benchmark coating technologies, and create advanced corrosion-resistant materials. It provides rapid insights on new formulation performances or surface treatments in extreme conditions and helps innovators make products ready for commercialization.

-

Product Testing

CASS is applied to judging the longevity of such materials in highly adverse circumstances, from automotive trims and hardware fittings to decorative metals. This assists in making sure that their surface finishes are not damaged, are attractive to the eye, and perform as required during their required service life.

Applications of Neutral Salt Spray Test

The NSS test consists of various applications, such as quality assurance, material and coating evaluation, failure analysis, and environmental simulation. Here are the key applications described in detail:

-

Quality Assurance

NSS testing mainly finds its application in routine quality assurance, confirming that metals, coatings, and plated components will resist corrosion under neutral salt spray conditions. These tests enable manufacturers to get consistent performance in their products and detect their defects early; therefore, the production of poor-quality items is minimized, and companies can stay within industry specifications before large-scale production.

-

Material and Coating Evaluation

It is used in various industries to test the durability of paints, zinc coatings, electroplated layers, and protective finishes. It compares various systems by exposing material to a specific quantity of salt spray and aids in assessing which coating systems will provide improved corrosion resistance for particular applications.

-

Failure Analysis

NSS testing can identify the root cause of products that fail when they shouldn't, simulating the process of corrosion in a controlled way. This lets an engineer study failure modes and locations, which enables them to pinpoint weaknesses, enabling improved surface treatments and preventing recurrence in future lots.

-

Environmental Simulation

The NSS test simulates naturally occurring salt, humidity, and moisture from either coastal or industrial complexes. These are simulated controlled environments that show ease in predicting long-term performance so as to be certain that components will still sustain the demands of the extreme environmental conditions throughout the life of the component, both structurally and aesthetically.

Advantages and Disadvantages of CASS & NSS Test

The Copper-Accelerated Acetic Acid Salt Spray (CASS) test is one of the most aggressive accelerated corrosion testing methods; it provides fast results in quality control and R&D for certain coatings. However, the real-world correlation is limited in all environments and for every material variant.

Copper Accelerated Acetic Acid Salt Spray (CASS Test)

Advantages:

-

Effective for High-Performance Coatings

It is designed and very effective in assessing the durability of high-performance and decorative coatings such as nickel-chromium and copper-nickel-chromium plating on materials like steel, zinc alloys, and aluminum alloys.

-

Quality Control and Process Improvement

This test is widely used in industries where quality control requires the identification of early signs of weakness or regression in production processes. The speed at which results are obtained enables rapid validation and improvement of coating technologies and electroplating processes.

-

Simulation of Severe Environments

The aggressiveness of the CASS test simulates very severe conditions that exist in real life, mostly the corrosive effects that occur during use in very harsh service conditions, like exterior parts in automobiles, marine applications, and aerospace.

-

Standardised and Reliable

The CASS test is a standardized test technique, which is characterized by international standards such as ASTM B368 and ISO 9227. This kind of standardization makes the results repeatable and comparable in the various laboratories and industries.

Disadvantages:

The disadvantages of CASS include limited real-world correlation, material limitations, operational challenges, and narrow scope.

-

Real-world exposure correlation is limited

Being an ultra-accelerated test, the CASS test cannot simulate all complex real-life environmental conditions, such as temperature fluctuations, UV radiation, and a variety of pollutants. The actual service life correlation has to be established for particular applications.

-

Material Limitations

The test is primarily suited for specific materials like aluminum alloys and chromium/nickel platings. For some general organic coatings, it is too aggressive, and for other metallic coatings, it may not be suitable unless a correlation has been demonstrated.

-

Operational Challenges

The temperature of the test is high, causing significant evaporation, which results in difficulties for the test equipment to meet both the required fog collection rate and the mass loss requirement simultaneously.

-

Narrow Scope

This specificity narrows the focus to salt- and acid-accelerated mechanisms of corrosion, neglecting other degradation factors like general atmospheric exposure.

Neutral Salt Spray Test (NSS)

Advantages:

Here are the advantages of neutral salt spray explained in detail:

-

Predictive analysis

It helps in the identification of areas of weakness in coatings, thus allowing early improvements in product development and helping to minimize costly field failures and customer complaints.

-

Supports product longevity

The neutral salt spray test helps in the selection of materials that will have a longer life and less maintenance, owing to the insight it provides on corrosion resistance.

-

Simulates real-world conditions

Although it is an accelerated test, the test is designed to simulate exposure to salt spray and humidity and therefore is a good indicator for products used in coastal and/or humid environments.

-

Identifies weaknesses

It is important to identify possible points of failure within a coating or surface treatment that can be corrected long before a product enters the marketplace.

Disadvantages:

Here are the disadvantages of neutral salt spray:

-

Unrealistic simulation

The test conditions are very unrealistic. They do not properly show the changing conditions of natural exposure. This includes variations in humidity, temperature, UV light, and other pollutants. For example, sulfur dioxide is one of these pollutants.

-

Poor correlation for some materials

It is not a reliable predictor of real long-term performance for all materials, such as for certain stainless steels, since the accelerated conditions may alter their corrosion behavior and mechanism.

-

Ranking capability only

Overall, the findings can only be used to rate or compare the corrosion resistance of different samples tested in a controlled environment. They cannot predict the actual service life of a product in a specific real-life situation.

-

Parameter variability

These test results depend on various factors, such as the sample placement angle and uniformity of salt fog deposition. Repeatability demands strict adherence to standards.

How to Choose the Right Corrosion Test for Your Materials

When selecting an appropriate corrosion test, it is crucial to take into account the type of material, the application, the industry, and the features to be assessed, such as neutral salt spray tests and copper-accelerated acetic acid salt spray tests. These tests fall into three main categories: field performance, service history, and accelerated corrosion tests. This includes neutral salt spray tests and copper accelerated acetic acid salt spray tests. Additionally, ascertain whether the objective is to optimize cost-performance or if there are specific compliance standards that must be fulfilled.