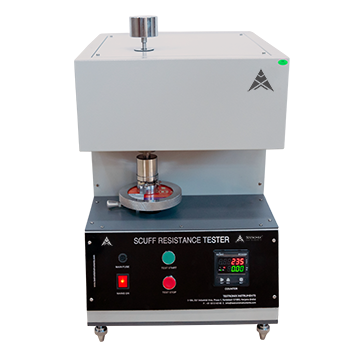

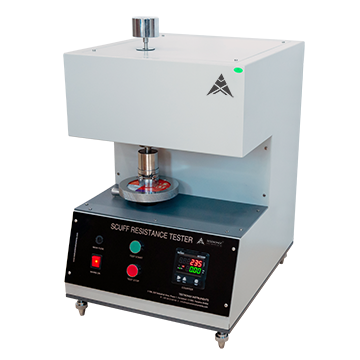

The Scuff Tester 21CFR is a very accurate instrument to evaluate the rub resistance between two stickers or any general printed material. The term scuff implies the rubbing of two materials against each other.

The Testronix scuff tester rubs two printed materials against each other face to face in the same plane at constant speed and rubbing pressure.

Testronix Instruments is leading manufacturer and supplier of Scuff Tester 21CFR in India. To get the best price, request a quote or call us now!

This instrument can also be used to prevent color transfer from one printed material to another or any coated surfaces during rubbing.

With the Testronix Scuff Tester 21CFR the manufactures can rest assured as we provide them with the best quality at affordable prices.

Testronix scuff resistance tester 21 CFR follows industry standards i.e ASTM F2497-05

The Scuff Tester 21CFR helps make sure printed labels, packaging surfaces and coated materials stay clear, readable, and durable. It is done by checking how well they hold up against rubbing or friction during handling and transport. It supports smooth quality control by showing how resistant a surface is to wear which helps prevent smudging, fading or damage that could affect product identification or appearance. Using this tool makes work easier because it provides consistent results that help teams spot problems early, reduce rework, and maintain compliance with regulatory expectations.

It also helps improve production processes by identifying weak areas in inks, coatings and finishes which help manufacturers to make modifications before items reach customers. With simple operation and dependable performance, the scuff tester supports both routine testing and detailed evaluations, making packaging more reliable, improving brand presentation and giving confidence that products will look the same from factory to shelf.

Applications

Testing label durability on pharmaceutical packaging.

Checking ink resistance on printed cartons and boxes.

Evaluating coating strength on cosmetic and personal-care packaging.

Assessing the wear resistance of food and beverage labels.

Verifying print quality for regulatory compliance.

Comparing different inks or coatings during product development.

Ensuring packaging stays readable after shipping and handling.

Motorized Weight arrangement on sample

Highly accurate test results

Provision of Set number of counts through Digital Preset Counter

Firm hold of test specimen

Motorized Geared system for scuff movement

Blow free design?

Display Digital (LED)

Sample Preparation templates 3 samples

Material Mild Steel powder coated

Highly accurate and precise results under uniform load and rubbing clamp movement

Accurate rpm of upper rotating discs

Highly accurate and precise results under uniform load and rubbing clamp movement

Accurate rpm of rotating discs using synchronous motor

User-friendly electronic controls and ergonomically designed feature

Designed as per standards ASTM F2497-05, BS 3110:1959?

Applications:

To check the scuff resistance/Rub resitance of:

Printed paper, carton package & board.

Labels, Laminates and flexible films?

Composite & Multilayer flexible pouches and packaging?

FMCG packaging and Aluminium Foils?

Inks on printed films and leather materials

Glossy/ Printed surfaces?papers.

Part Compliance to 21CFR Part 11?

1. Access Control & User Management

Role-based user accounts (Operator, Supervisor, Administrator).

Unique user ID and password required for login.

Automatic logout after inactivity.

Password policies configurable as per organizational SOPs.

2. Audit Trail (Non-erasable, Computer-Generated)

Every action (test start, test stop, parameter editing, report generation, data export, login/logout) is automatically logged.

Audit trail includes:

User name

Action performed

Old value vs new value

Date and time

Audit trail cannot be modified or deleted.

3. Electronic Signatures

Supports multi-level electronic signatures as per Part 11 Subpart C:

Test Performed By

Reviewed By

Approved By

Each signature includes:

Printed name

Date & time executed

Meaning of signature (Approval / Review / Creation)

4. Data Integrity & Security

Encrypted data storage.

Protection against unauthorized data modification.

Automatic backup and database protection available.

Test results cannot be overwritten; new entries are created for every run.

Software ensures ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, Accurate).

5. Report Generation & Export Controls

Reports can be generated in PDF, Excel, or secure proprietary formats.

Export rights are controlled by admin privilege.

Each report contains unique identification and time stamps.

Counter 4- digit Digital Preset type

Least Count of counter 1

Rotational Speed 60 rpm ± 2 rpm

Lower Motor capacity ¼ HP

Upper Motor capacity 10 kg/cm² torque motor

Diameter of Upper Clamp 48 ± 2 mm

Diameter of Lower Clamp 120 ± 2 mm

Power 220V, 50Hz, single phase

Dimensions 420x550x680 mm

Claim FREE copy of our latest Product Catalog.

Tell us where should we send your copy?

Tell Us What Product You are Interested In?