Reviewed by Anurag Mishra (Sr. Technical Consultant)

It is extremely crucial for manufacturers of various products to guarantee the long life of their products to attract customers with a sense of assurance. Manufacturers undergo extreme testing measures to claim such guarantees. It is an extremely important process to undergo tests before claiming such guarantees as these materials are exposed to the environment which makes the material used in the final product prone to rusting & corrosion.

To avoid such rusting & corrosion on material or to avoid degraded quality material in the production process of final goods, manufacturers undertake environmental chamber tests to evaluate the quality of material against various hazards caused due to exposure to the environment.

The finest lab testing instrument manufacturer, Testronix has come up with an outstanding lab testing equipment known as the salt spray test chamber. The instrument has truly revolutionized the conduction of salt spray tests over variable materials to determine the changes in their properties or to assess the ability of these materials to withstand rusting.

The instrument has an extremely futuristic working mechanism that allows the manufacturer & the operator to attain maximum accuracy when it comes to simulating real-life corrosion-friendly environments.

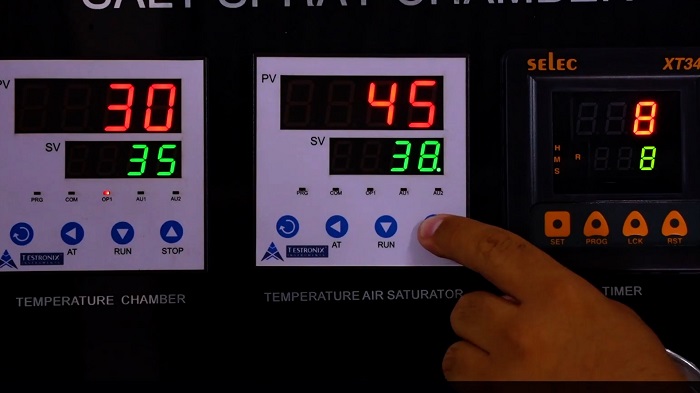

The salt spray test is conducted with absolute facile due to the futuristic working module of the instrument. The instrument is equipped with an enhanced control panel that is connected to the electrical chamber for easy functioning & hassle-free operation.

The salt spray test begins with the placement of the sample inside the inner chamber.

The inner chamber is equipped with three sample positioning plates which are 1) the V-group, 2) the specimen card plate & 3) the hanging sample assembly.

After the placement of the specimen, the operator must close the canopy which ensures maximum insulation inside the inner chamber and disallows the external environment to hamper the inner environment and thus the salt spray test results.

The salt spray tester has a reservoir tank that is also called the water carrier of the instrument is filled with demineralized water. The DM water is mixed with salt to make it a proper solution in a ratio of 95:5 respectively.

The solution from the reservoir tank is supplied to the inner chamber through pipes and thus inlet ports.

Another important aspect of the corrosion tester is the air pressure chamber which is designed to elevate the temperatures of ambient air and moisturize the air with the help of DM water. The air pressure is transferred & exerted into the inner chamber with the help of extremely futuristic equipment called the igus & the atomizer.

The elevated air pressure mixes with the salt solution from the reservoir tank are powered into the inner chamber through igus & atomizer in the form of a concentrated fog. The fog is equally spread all across the inner chamber with the help of the fog dispenser with special carvings.

The operator can adjust the timings of the test with the help of the preset timer associated with the control panel of the salt spray tester. Once the testing time is achieved, the instrument activates the air purge which settles down the fog inside the inner chamber and the operator can simply open the canopy with the control panel and take the specimen out for assessment.

This is how the corrosion tester performs the test with absolute facile & minimal hassle to the operator as the instrument offers feather touch buttons, a simplistic control panel & a microprocessor-based digital display of the preset timer.

All the salt spray tests are possible to be conducted with such ease due to the inculcation of advanced characteristics within the instrument.

The instrument is enriched with features that support cutting-edge technology to aid manufacturers in achieving maximum accuracy and thus ensure the perfect material utilization in the production process of the final product.

The foremost feature is the build of the instrument itself. The FRP materials used as a layer in the walls of the inner chamber contribute loads to its maximum insulation capabilities allowing the manufacturer to achieve high levels of accuracy. The other two layers consist of glass wool & mild steel capture the heat & prevent it to escape as well as provide durability to the instrument respectively.

The assembly of silicon bag heaters in the walls of the inner chamber is an outstanding feature imbibed by the manufacturers of Testronix. The integration of these heaters inside the walls allow the instrument to spread uniform heating inside the chamber without any external fan.

The instrument has a reservoir tank that carries DM water for the conduction of the test. The reservoir tank is offered with a layer sponge filter & water level low indicator that allows the operator to conduct testing with a perfectly mixed solution that is away from impurities and determines the water level to streamline the salt spray test.

The salt spray test chamber is also equipped with various other safety features like the automatic cut-off after achieving the adjusted time, air saturator temperature overshoot alarm, inner chamber temperature overshoot alarm, over/under voltage alarm, etc. helps the operator to conduct the test free from any jeopardies or hazards that can be caused.

The instrument has an extremely simplistic working module along with customizable options of variability in the sizes of the inner chamber as well as the reservoir tank as per the necessity of the specimen being tested.

There are a lot of other features that you can get your hands on right away by booking the instrument from the finest Lab testing Instrument manufacturer – Testronix.

Do not force any delay in buying the most revolutionary lab testing instrument. To order the instrument, you can reach out to our website or call our executive at +91 9313140140. We will highly regard your feedback on the servicing & buying experience at info@testronixinstruments.com.