Corrosion testing is a highly popular technique used in establishing the resistance of the metals, coating and surface treatments to corrosion. Salt spray (or salt fog) testing has three very popular references: ASTM B117, ISO 9227, and JIS Z 2371. Despite the fact that all three have several similarities, they have certain technical distinctions, regional uses and specific needs.

What are Accelerated Corrosion Tests?

The salt spray or accelerated corrosion test is generally conducted in a chamber that holds a specific amount of water solution with a consistent amount and type of salt containing the materials, coatings, or devices. It is done under test for a defined period outlined in the standard.

As an aggressive shared test, the salt spray test allows you to evaluate the behavior of materials that are likely to be subject to corrosion in their normal operating conditions or while they are in use.

What is ASTM B117 Salt Spray Test?

ASTM B117 is a standardized method used to perform the salt spray (fog) test, a widely used accelerated corrosion test for metals and coated metals. This ASTM Standard is popularly used for the purpose of testing the corrosion resistance of coated or uncoated metal substrates in a salt-mist test environment at high temperatures.

ASTM B117 Procedure

ASTM B117 consists of several procedural steps, which are described below:

-

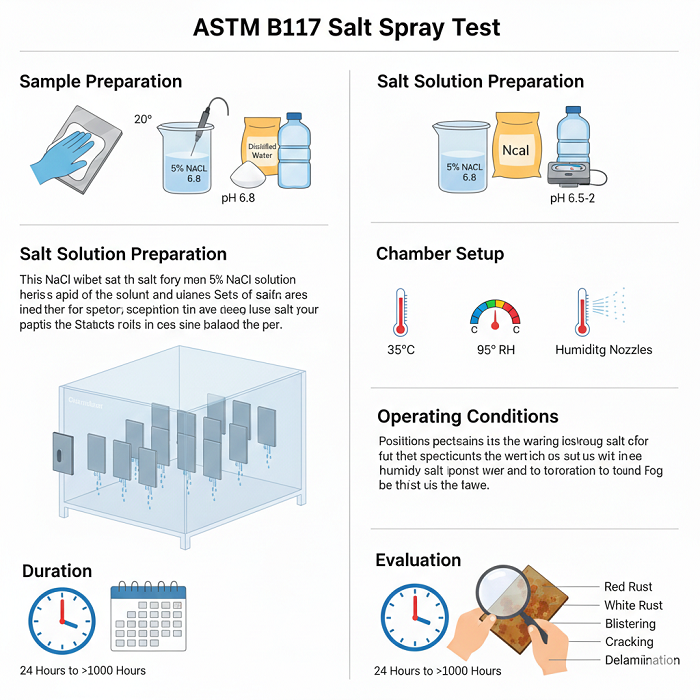

Sample Preparation

Test specimens were prepared by cleaning them of any grease, oil, dust, or other contaminating substances that may interfere with corrosion test results. Coated panels are conditioned for the anticipated service conditions. Properly conditioned samples provide uniform exposure for accurate comparison of corrosion-resistant performance.

-

Salt Solution Preparation

For preparing a salt solution, a 5% sodium chloride solution was prepared using distilled water as the solvent to eliminate impurities in the working solution. The pH of the prepared working solution was adjusted to fall within the range of 6.5 - 7.2, thus maintaining neutrality. Proper concentration and pH control produce consistent fogging conditions and provide consistent testing conditions for comparative corrosion testing.

-

Chamber Setup

Specimens are positioned in the test chamber at an angle of 15° - 30° from vertical. This orientation aids in preventing the accumulation of direct water droplets onto the specimens while still providing a uniform fog exposure. The specimens must be positioned such that they do not contact one another to allow for uniform air circulation and corrosion conditions during the testing period.

-

Operating Conditions

The chamber's temperature is kept at 35°C under the ASTM B117 operating conditions to provide consistent corrosion behavior. A fine, continuous, wet salt spray is produced using atomizing nozzles, and relative humidity is maintained at approximately 95% ± 2% RH to provide uniform salt deposition and to increase the rate of corrosion.

-

Duration

The ASTM Test Method B117 does not define how long something should be tested. It states it is going to be as long as required per the product's specifications or requirements provided by customers. Most products are typically taken between 24 hours and more than 1,000 hours before they are approved by the customers.

-

Evaluation

As soon as testing has been completed, the specimens are lightly washed with deionized water to remove any remaining salt on their surface (without disturbing any corrosion on the specimen). The surface of the specimen is visually examined by searching for red rust, white rust, blistering, cracking, and delamination of the coating that may exist.

What is ISO 9227 Salt Spray Test?

ISO 9227 is an international standard for conducting neutral salt spray (NSS), acetic acid salt spray (AASS), and copper-accelerated acetic acid salt spray (CASS) tests. It helps in evaluating the corrosion resistance of metallic materials and protective coatings.

This standard also describes the procedure to use while conducting neutral salt spray, acetic acid salt spray, or copper-acetic acid salt spray tests (to find defects, pinholes, or damage).

ISO 9227 Procedure

ISO 9227 consists of several procedural steps, which are described below:

-

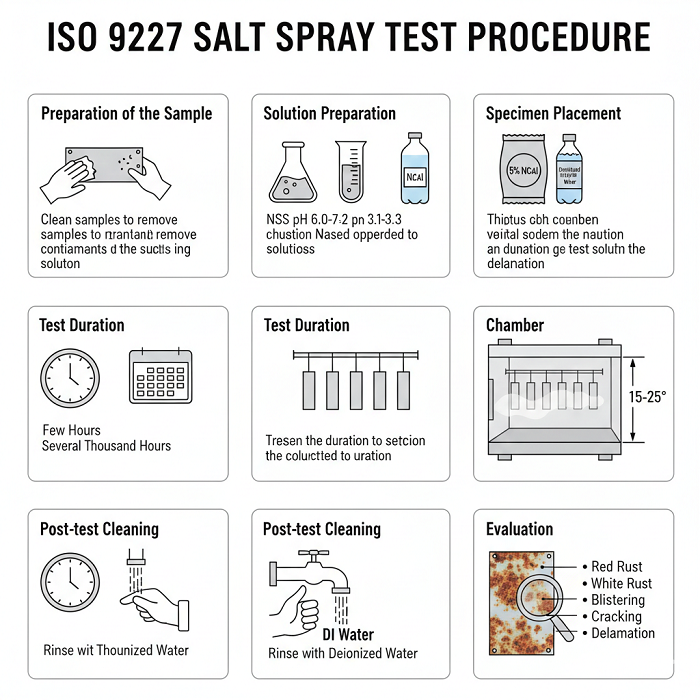

Preparation of the Sample

Samples to be tested must be properly cleaned to eliminate grease, dirt, oil, and other contaminants that may affect the corrosion behavior of each sample. Different standards determine the type of sample and how many samples to prepare. Proper preparation allows for an accurate comparison and reliable assessment of the performance of the coating or material.

-

Solution Preparation

According to ISO 9227:5, ±1%, a high-purity sodium chloride solution (NSS) should be prepared with distilled or deionized water. The pH should be maintained between 6.0 and 7.2 for NSS (normal saline solution). If the pH is below 7.0 for NSS and above 6.8, then the solution has an elevated chloride ion concentration (NSS). The aqueous acidic solutions of NSS also contain copper(II) chloride by adding cupric sulfate to an acidified solution to create the aqueous solution of ammonium acetate (AASS).

-

Specimen Placement

Test specimens can be tested at an angle of 15 to 25 degrees off vertical, with the sample position typically oriented towards the top of the chamber. Sample position assists in maximizing and distributing uniform spray contact without forming solution puddles, thus allowing a consistent level of corrosion exposure to all test samples.

-

Test Duration

The length of time that any given piece of equipment is exposed to a corrosive environment is a function of both the type of item being tested and the test specifications. Hence, for some items, tests could take anywhere from a few hours to as long as several thousand hours, whereas other items would not have fixed specifications for testing duration.

-

Post-test Cleaning

Specimens need to be quickly rinsed with deionized water to remove any remaining salt deposits after being subjected to the test. This should be done carefully so that corrosion products on the specimen are not moved. After rinsing, the specimens are allowed to dry under controlled conditions so as to ensure that they can be inspected accurately after the test.

-

Evaluation

Observing for signs of corrosion (such as rust growth, blisters, cracks, or coating delamination) is completed visually after the specimens have dried completely. Each product must also have outlined in its respective specification what constitutes that product's acceptable state of corrosion for the purpose of evaluating the result of the corrosion test.

What is JIS Z2371 Salt Spray Test?

JIS Z 2371 is a Japanese industrial standard that specifies the method for conducting neutral salt spray (NSS) tests to evaluate the corrosion resistance of metals and coatings. It defines the methods for accelerated corrosion resistance on various metals and on surface coatings applied to those metals (called plated or painted) using a saltwater fog chamber.

The purpose of using these salt or saltwater fog chambers is to simulate real-world corrosive environments to be used with the materials that are used primarily in automotive applications and manufacturing, and more importantly, to evaluate the long-term durability of those materials.

JIS Z2371 Procedure

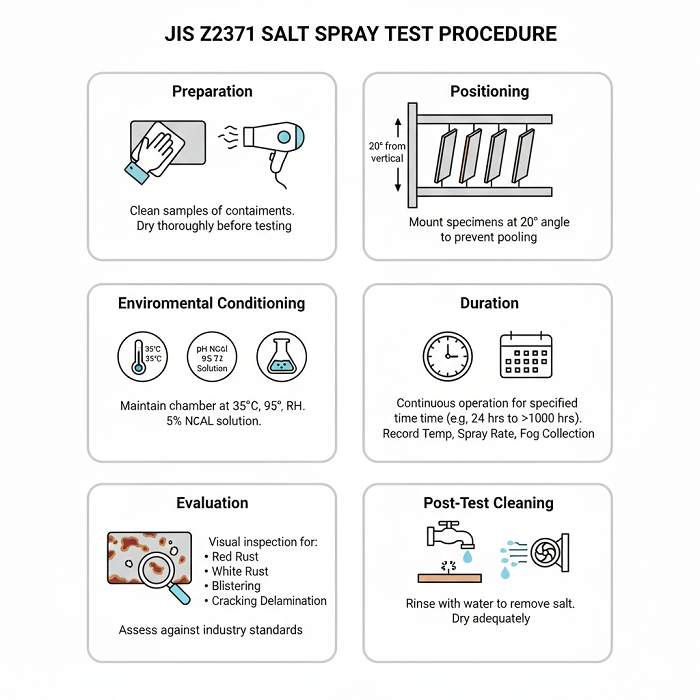

JIS Z2371 consists of several procedural steps, which are described below:

-

Preparation

All test samples must first be cleaned thoroughly of all contaminants, such as oils and grease, and also dried adequately before being placed in the chamber for testing. Samples must be placed carefully inside the chamber so that they are not directly exposed to the spray nozzles and so no solution droplets are allowed to drip between the samples.

-

Positioning

All test samples must be mounted so that the angle of each sample is approximately 20 degrees from the vertical. The samples must be angled to prevent an excessive accumulation of solution on the surfaces and maintain consistent corrosion activity of all exposed surfaces during testing.

-

Environmental Conditioning

The test is conducted using a 5% sodium chloride solution made from distilled or deionized water. The pH of the solution is maintained between 6.5 and 7.2, and the temperature in the chamber is maintained at 35 degrees C, while the total rate of spray is regulated between 1 and 2 mL per 80 cm² per hr.

-

Duration

The test is going to be run as a continuous operation for the specified time to be determined to satisfy the specifications for the product. Throughout the exposure to the chamber, the temperature, the amount of spray, and the amount of fog collected are recorded to ensure that all environmental conditions are stable and to enable the results of the corrosion tests to be reproduced.

-

Evaluation

After the test specimens have been exposed to salt fog, they are washed with water to remove any remaining salt deposits and then adequately dried. All of the exposed surfaces are evaluated for corrosion products (rust or oxide buildup) and coating failure using the acceptance criteria specified in the appropriate industry standards for the product.

Which is the Right Standard for Accelerated Corrosion Testing?

Choosing the right standard totally depends on one’s target market and the specific material for the person who is testing. While all three define the parameters for salt spray (fog) testing to assess corrosion resistance, they serve different geographical and industrial needs:

-

ASTM B117: In North America, ASTM B117 sets the standard for the industry, with this standard being the most commonly used worldwide. ASTM B117 is an NSS test, which is an automated and continuous method to test metal coatings and select materials via exposure to a neutral saline solution.

-

ISO 9227: ISO 9227 is the global international standard that is not as rigid as ASTM B117. The ISO 9227 standard combines three independent procedures (AASS, NSS, and CASS) into one, where all three methods are considered as equals within the globally recognized ISO 9227 standard.

-

JIS Z 2371: JIS Z 2371 is the Japanese Industrial Standard. The JIS Z 2371 Standard defines the predominantly required standards for the Asian region about automotive and electronics supply chains located in Japan.

Conclusion

ASTM B117, JIS Z 2371, and ISO 9227 specify the techniques of corrosion performance evaluation in accelerated weathering conditions. ASTM B117 and JIS Z 2371 are neutral tests, but ISO 9227 has some variants.

When deciding which testing standard should be adopted, take into account all the market, regulatory, and customer requirements. To select the right equipment that is compliant with ASTM B117, JIS Z 2371, and ISO 9227, always purchase instruments from reliable manufacturers like Testronix Instruments or schedule a call with us.