Reviewed by Anurag Mishra (Sr. Technical Consultant)

The edge crush strength of corrugated boxes will help you to make sure that the boxes delivered are of high quality. You can easily test the edge crush strength of corrugated boxes with the help of the Testronix edge crush tester. This lab testing instrument helps you to measure the edge-wise compression strength of boxes with ease.

Here in this blog, we are going to provide you with the importance of an edge crush tester and how this lab testing equipment is helpful in testing the quality of corrugated boxes. We will also discuss the importance of the edge crush test in the paper and packaging industry.

The Edge Crush Test (ECT) for corrugated boxes measures the compressive strength of the board by determining how much force is needed to crush the edge. It indicates a box’s ability to withstand stacking pressure during shipping, storage, and handling. Higher ECT values mean stronger boxes with better load-bearing capacity.

Overall, the strength measurement of the edges of a box using edge crush testing helps determine the box’s stacking strength, making it a key factor in packaging design and logistics planning.

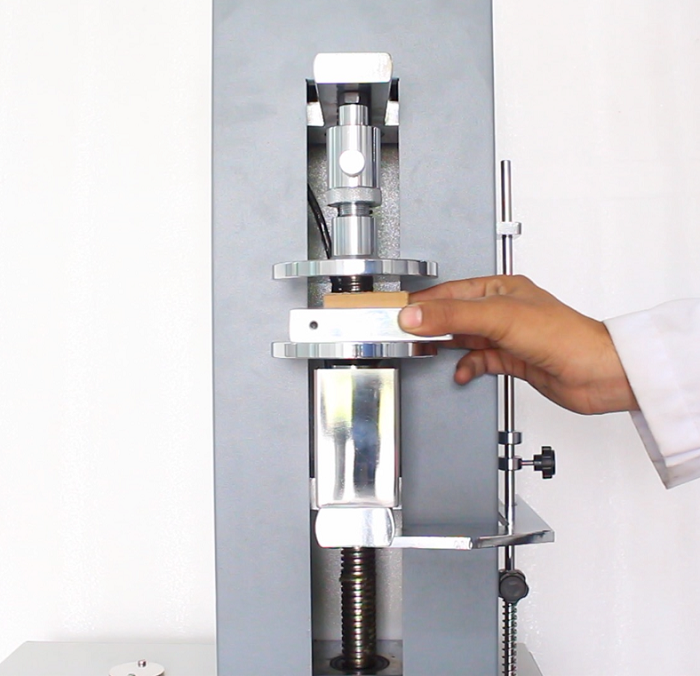

The Edge Crush Test (ECT) measures the edgewise compressive strength of corrugated board. Specifically, it assesses how much force the board can withstand when pressure is applied to its edge, which is the most critical area during stacking. In this test, a small section of the corrugated material is placed vertically in a testing machine, and a compressive load is applied until the sample buckles or fails.

The Edge Crush Test (ECT) formula is:

ECT = Force Applied (N) / Sample Width (mm)

Here,

Force Applied (N): This is the peak force needed to crush the sample before collapse.

Sample Width (mm): This is the sample width of the corrugated being tested.

ECT Value: The calculated value that signifies the edge crush strength of the material.

This calculates the ability of a material, specifically corrugated cardboard, to resist collapsing under edge-wise compression. ECT, measured in pounds per inch (lb/in) or kilonewtons per meter (kN/m), reflects the strength and endurance of a material when stacked.

An Edge Crush Test calculator calculates a material’s edge crush strength – the resistance to collapsing when compressed along its edges. Such calculators usually require as input the force applied in testing and the dimensions of the sample, and then calculate the ECT value, usually in terms of pounds per inch or kgf/cm.

ECT calculators simplify the process of calculation by automating the formula to find the ECT value. They usually integrate the formula of ECT = Force applied / Sample width.

The use of a calculator is time-saving and provides accuracy and consistency in ECT calculations.

Example:

For instance, a corrugated board sample is 100 mm in width. In an ECT test, the maximum force used to crush the edge is 400 Newtons (N).

Force used (N): 400 N

Sample width (mm): 100 mm

Calculation:

ECT = 400 N/100 mm = 4 N/mm or 4000 N/m

The ECT value is determined by the force needed to crush the edge of the corrugated board test sample, usually expressed as pounds per inch. The higher the ECT value, the greater the box strength against crushing forces, especially upon stacking. The formula ECT = Force (N) / Sample width (mm) is used to calculate the ECT value.

Steps to Calculate ECT:

Sample Preparation – Cut a corrugated board strip to standard dimensions (usually 25 mm wide).

Positioning – Place the sample vertically (on its edge) between the compression plates of the testing machine.

Load Application – Apply a compressive force at a constant rate until the board begins to crush or collapse.

Measurement & Calculation – Record the maximum force applied before failure, then divide it by the sample width to calculate the ECT value.

The most common edge crush testing (ECT) standards are DIN EN ISO 3037, TAPPI T811, ISO 13821, TAPPI T838, and TAPPI T839. These are the standards for testing the edgewise compressive strength of corrugated fiberboard, which is important in verifying the stackability and durability of corrugated packaging.

DIN EN ISO 3037: This European standard prescribes a procedure for the determination of the edgewise crush resistance of paraffin-free corrugated cardboard.

TAPPI T811: This TAPPI standard outlines a test method for the determination of the compressive strength of corrugated fiberboard, with emphasis on the edges, perpendicular to the flutes.

ISO 13821: This ISO standard prescribes a procedure for the determination of edgewise crush resistance with waxed edges.

TAPPI T838 and TAPPI T839: TAPPI standards are also applied in edge crush testing and include specific procedures for test conditions, clamping, and sample preparation.

The edge crush test (ECT) and burst strength test are utilized to assess the strength of corrugated cardboard, but they test different characteristics. ECT tests how much a corrugated board resists crushing along its edges and is mostly testing stacking strength. On the other hand, burst strength tests how much the board resists puncture or bursting and how much internal pressure the board can withstand.

Here is the key difference between the edge crush test and the burst strength:

| Feature | Edge Crush Test (ECT) | Burst Strength Test |

| Purpose | Measures edge crushing resistance | Measures puncture resistance or bursting strength |

| Focus | Stacking strength | Internal pressure and puncture resistance |

| Test Method | Compression force applied to the edge | Pressure is applied to the bulging diagram |

| Significance | Determines how much weight a stack can hold | Determines how well the box resists internal punctures |

The edge crush test is used to determine how well cardboard resists cross-sectional crushing pressures. The edge crush tester aids in determining the box's edge-wise strength, which is important since the box's edges are designed to be strong in order to provide protective strength against compressive pressures. As a result, the edge crush tester assists the maker in delivering the best box while assuring the material's protective potential.

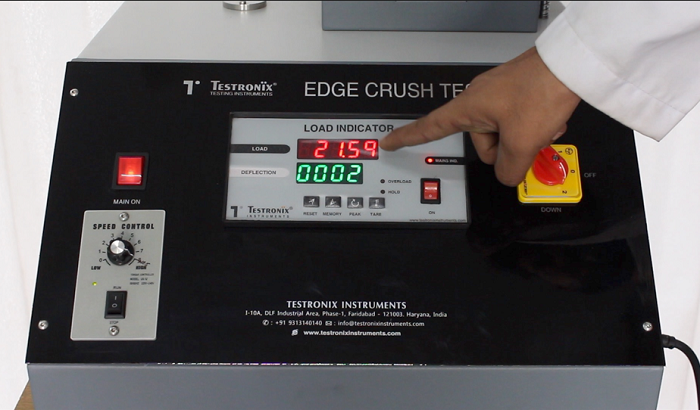

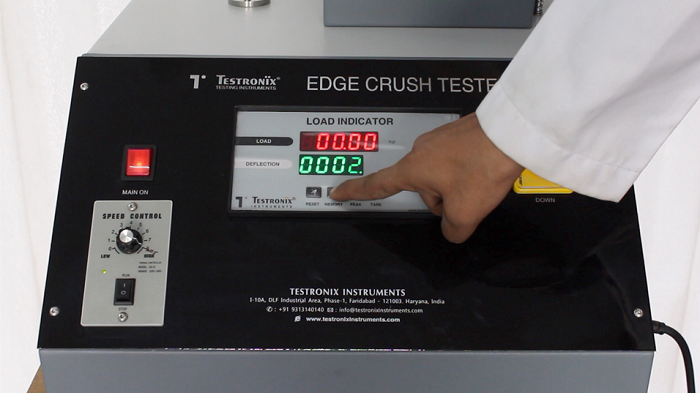

This test done by the edge crush tester testing instrument will help you to determine the strength and quality of corrugated boxes that can be crushed at the time of transportation and handling. Testronix offers a high-quality edge crush tester digital model that makes it easy for you to conduct the test. Below we have mentioned the features you will get with the help of this lab testing instrument.

Testing the stacking ability of a box's edge is the most feasible and repeatable approach to measure how well it will hold its form under vertical weight during transit. For many years, many corrugated box manufacturers in the packaging business have relied on this lab testing instrument to ensure that their consumers receive reliable products.

With these features and technical specifications, it will be easy for you to conduct the test using the Testronix edge crush tester. Whenever you buy an edge crush tester then you can simply maintain it with these 5 easy tips. At Testronix, our instruments will be designed by keeping all industry standards in the mind. The ECT, or Edge Crush Test, evaluates corrugated cardboard's capacity to protect products during storage or transit.

It is crucial in the paper and packaging business since it aids in determining the compression forces that a box can withstand in order to ensure the safety of goods and products. To know about the edge crush tester price, or want to conduct an online demo for this lab testing equipment, give us a call at +91 9313140140 or email us at info@testronixinstruments.com. Our team of technical experts will assist you with all your queries.