Reviewed by Anurag Mishra (Sr. Technical Consultant)

Packaging of products & tools is widely accepted in corrugated boxes due to their high-quality and ergonomic body structure which allows the shipment operators to carry them in a minimum required space when empty and still form a durable box when needed. The top-notch invention is used all across the globe for freight, shipment, transportation of products even for inter-continent travel.

The corrugated boxes can be folded like a textile and can be carried with absolute ease when empty, however, when the boxes are filled with products & tools inside them, it becomes difficult to manage space as shipments are ordered on a large scale and the transport space is always limited. Therefore, shipment operators stack these boxes on each other for easy & smooth saving of space and allow maximum products to be shipped in one go.

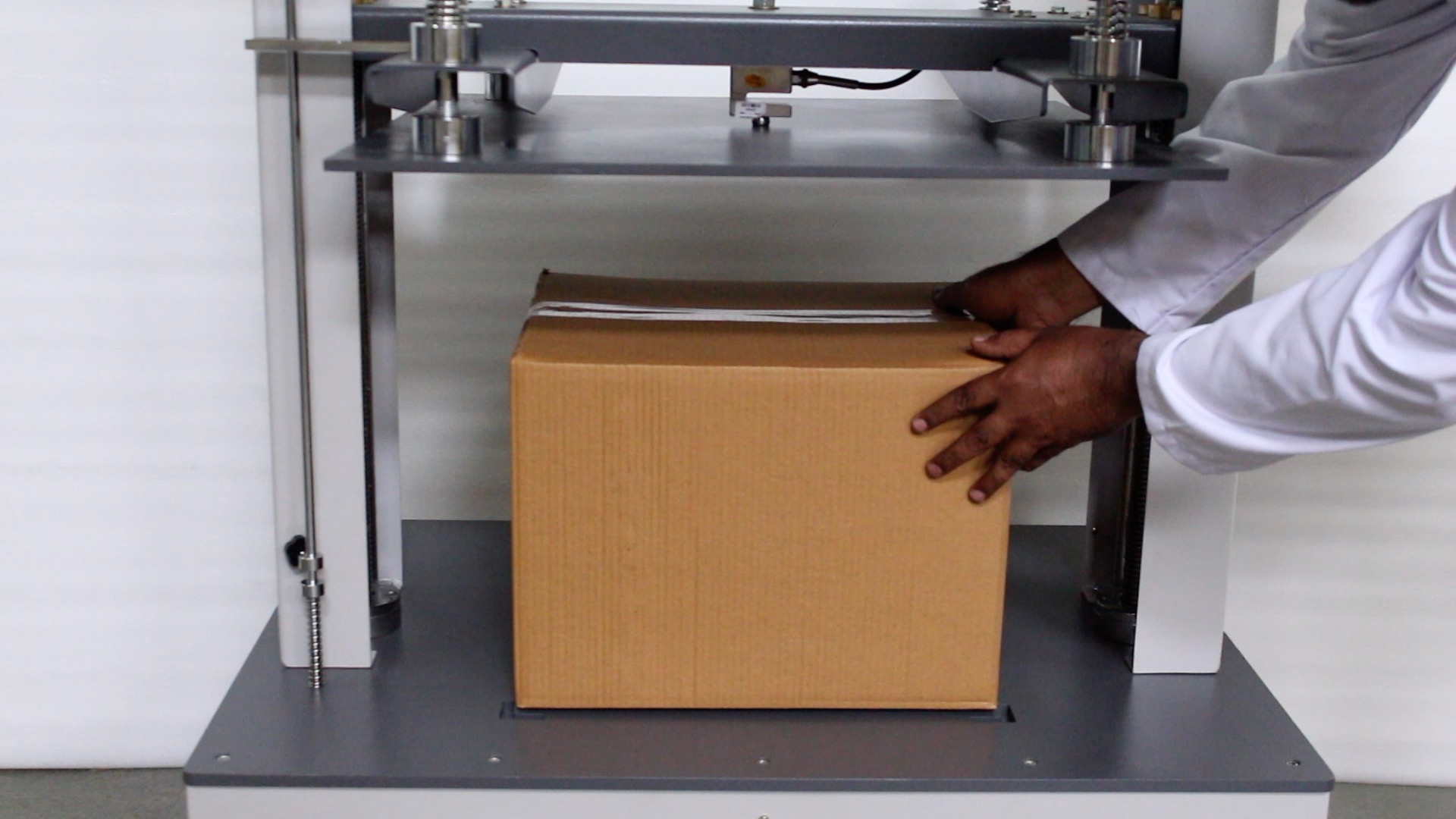

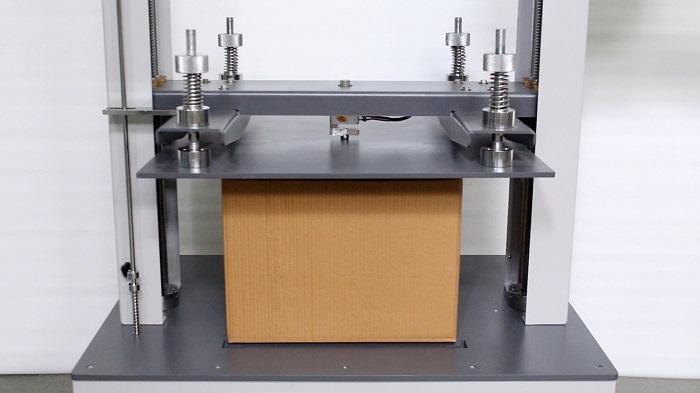

Stacking these boxes on one another can be a hassle to the durability of the box in the case of weak edges or a compromised quality corrugated sheet utilized for the production of these corrugated boxes. To get away from such issues and curb them smoothly, the leading lab testing instrument company – Testronix has come up with an outstanding lab testing equipment called the box compression tester.

The instrument is designed to simulate real-life stacking that a corrugated box experiences during storage or transit. This evaluates the ability of corrugated boxes to withstand compression when stacked and attain higher quality levels if there is uncertainty.

The box compression tester manufacturer ensures that the instrument is equipped with an extremely easy-to-use working module that allows the operator to generate familiarity with the instrument expeditiously and perform precise simulations.

All these testing measures are conducted with utmost precision in order to attain the topmost accuracy while imitating the stacking of boxes.

The instrument has certain specifications that are necessary to be given adherence to precise information about the instrument.

These are all the necessary specifications that are important to be taken care of while conducting the box compression testing.

Get yourself the topmost lab testing instrument with utmost accuracy, designed by the leading lab testing manufacturer i.e. Testronix.

Conduct perfect & precise box compression testing by booking the instrument from our website. Clear all the confusion by getting your questions answered by an executive on the phone at +91 9313140140 or directly e-mail us your required specs & features at info@testronixinstruments.com.