Reviewed by Anurag Mishra (Sr. Technical Consultant)

With the rising consumption of PET bottles & elongated jars, the demand for higher quality is also subsequent. Such bottles and containers are consumed in a density of millions on a daily basis therefore, it becomes necessary to make sure that the end-user receives a flawless product.

There are certain aspects of measuring the quality of these bottles & containers to attain maximum user satisfaction thus, brand reputation. One of the key aspects of quality measurement is to perform the vacuum leak test. This test enables a manufacturer to measure the leakage in the bottles & containers in order to aid the uncertainties.

Testronix has come up with a high-end lab testing instrument to assist the manufacturers from the PET industry in identifying leakages in the manufactured bottles & containers. The top-notch lab testing instrument is called the vacuum leak tester for bottles.

The vacuum leak tester is designed ergonomically to measure the vacuum leakage and seal integrity of bottles & containers by conducting a vacuum leak test.

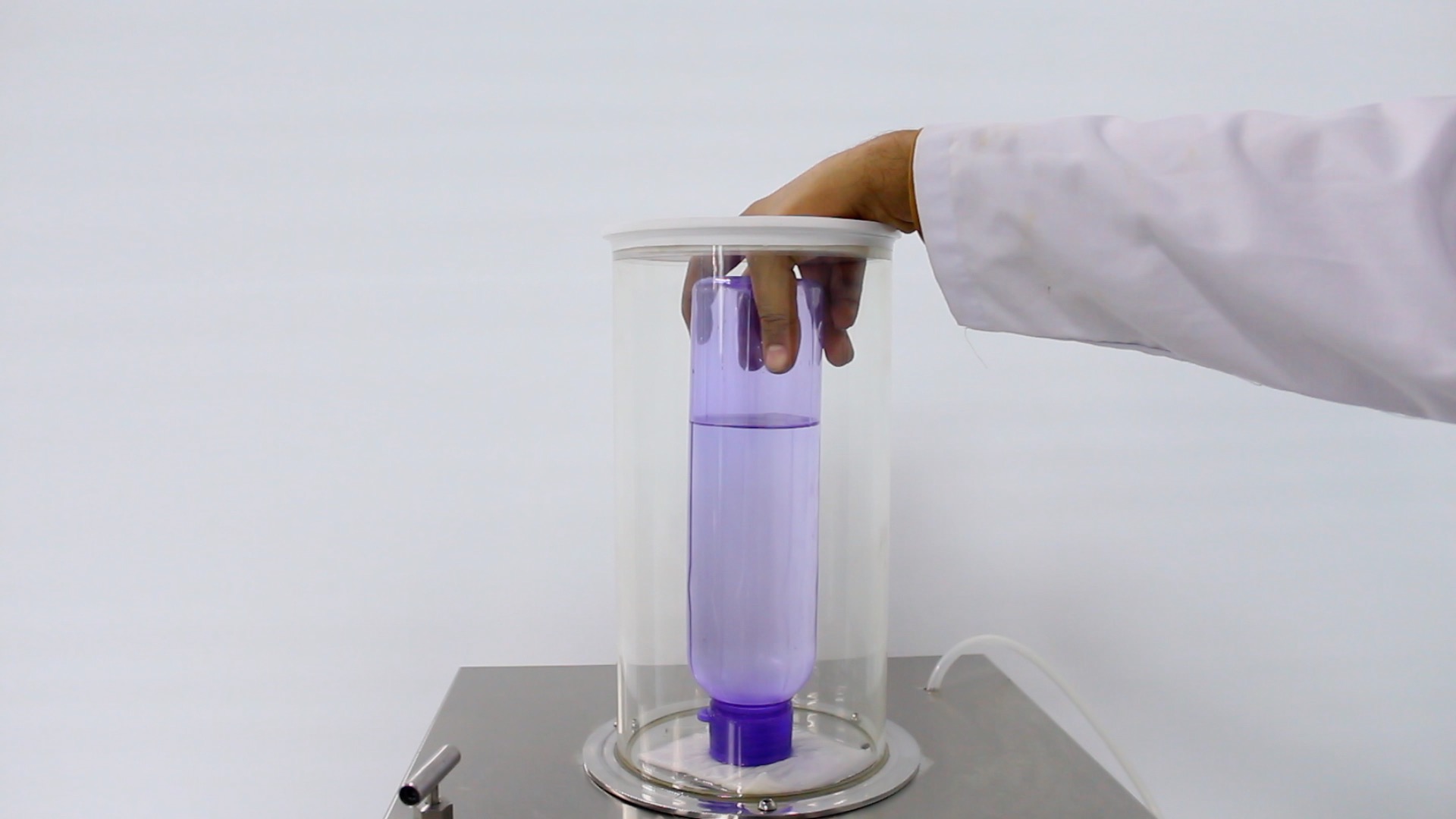

The test is conducted by simply placing the manufactured bottle in the dedicated specimen holder called the desiccator. The desiccator is tightened with a gas kit to ensure that no air pressure passes through the outside atmosphere within the chamber.

The air pressure is exerted into the chamber forming a vacuum around the specimen through the PU pipe. The pressure is adjusted through a pressure knob situated at the outside of the instrument.

The dial gauge at the outside enables the operator to monitor the air pressure frequency within the chamber, in case the bottle & the container remain intact and show no signs of leakage of the filled liquid, the specimen is passed. However, if there are leakages at a certain pressure, the specimen fails the vacuum leak test.

There are certain parameters necessary to be taken care of while performing the test with the vacuum leak tester.

Certain parameters are defined to achieve higher levels of accuracy while conducting the test to measure the leakages in bottles & containers. These parameters must be considered with utmost diligence to gain precise results consistently.

This vacuum leak tester for bottles designed by Testronix simplifies the answer to the budding question – How to find vacuum leaks in bottles?

These are some of the high-end features possessed by the vacuum leak tester for bottles. These features are the foremost reason for the assurance of manufacturers of the PET bottle industry.

This high-end lab testing instrument helps the manufacturers assess the leakage and seal integrity of bottles & containers in order to ensure maximum consumer satisfaction. If you also want to enhance the quality of your manufactured products, get your hands on this vacuum leak tester for bottles. The instrument is an answer to the prevailing question – How to find vacuum leaks in bottles. Seek more information on our website or contact us at +91 9313140140 or e-mail us at info@testronixinstruments.com.