Reviewed by Anurag Mishra (Sr. Technical Consultant)

Have you ever wondered what goes into testing the strength of materials used in packaging? From paper to plastic, a bursting strength tester is essential for ensuring the durability and reliability of various packaging materials. The Burst tests are conducted to maintain product integrity during shipping and handling.

Now, let us discuss the range of materials that can be tested using a bursting strength tester. So, let us get started!

Bursting strength testing is a crucial method for evaluating the strength and durability of various materials used in packaging, such as paper, plastic, and textile products. This testing process measures the maximum amount of pressure that a material can withstand before it ruptures or bursts. It is an essential quality control tool for manufacturers to ensure that their products meet minimum safety standards and can withstand the rigours of transportation and handling.

This is an important quality test that can be conducted using the high-quality lab testing instrument known as a burst strength testing machine. This high-quality laboratory testing equipment has been designed with highly advanced features and is available at the best price.

If you are thinking of buying a bursting strength tester then we recommend you consult with Testronix Testing Instruments. We offer different models of this quality testing equipment including bursting analogue, bursting tester pneumatic, bursting strength tester digital with Printer, bursting strength tester pneumatic computerized etc.

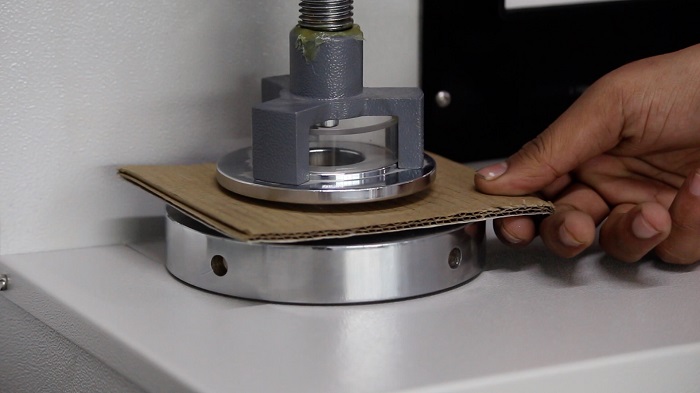

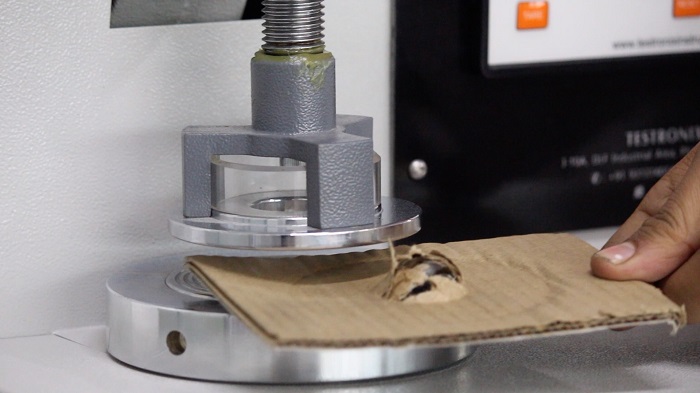

The primary purpose of bursting strength testing is to determine whether a material can handle its intended use without breaking or tearing under stress. In this case, bursting strength testing will simulate the stresses that the box may experience during transportation by subjecting it to increasing air pressure until it ruptures.

Bursting strength testing is a critical quality control method that ensures the reliability and safety of various products. It is essential for manufacturers to understand and conduct this test accurately to meet industry standards and deliver high-quality products to consumers.

The principle behind a Bursting Strength Tester is relatively simple – it applies hydraulic pressure to a circular area of the material being tested until it bursts. The results are then displayed on a gauge in pounds per square inch (psi) or kilopascals (kPa). This measurement reflects the strength and integrity of the material and helps manufacturers determine if it meets their specific requirements.

In most cases, products go through several stages during transportation from manufacturer to consumer. They may be stacked on pallets or loaded into trucks where they can experience significant external pressures during transit. If these products lack sufficient bursting strength, they could rupture under stress leading to damage or contamination.

Moreover, regulations require certain industries like food packaging to adhere to specific standards regarding bursting strength. These guidelines ensure that products can withstand internal pressures caused by heat-sealing processes without compromising their integrity.

Bursting Strength Testers play a crucial role in the quality control process of various industries. They help manufacturers determine the durability and strength of their products, ensuring they meet industry standards and consumer expectations.

There are different sets of samples that can easily be tested using a bursting strength tester. This includes paper, fabrics etc.

Let us know more about these samples in a brief way:

Paper is one of the most commonly tested materials with a bursting strength tester. This includes various types of paper such as kraft paper, corrugated cardboard, tissue paper, and more. The test is used to determine the maximum amount of force that can be applied before the material ruptures or bursts under pressure.

Plastic films are widely used in packaging and manufacturing industries due to their durability and flexibility. However, different types of plastics have different levels of strength and resistance against external forces. A bursting strength test can help determine the structural integrity and performance of plastic films, bottles, containers, and other products.

Fabrics are another category of materials that can be tested using a bursting strength tester. This includes woven fabrics such as cotton, linen, silk as well as non-woven fabrics like felt or fleece. The test helps determine how much stress or tension a fabric can withstand before tearing apart.

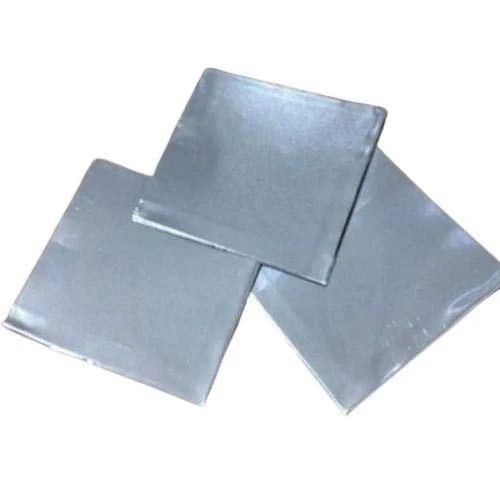

Aluminium foil is commonly used for packaging food items due to its ability to keep food fresh for longer periods by preventing air from entering the package. Bursting strength tests on aluminium foil measure its resistance against punctures or tears caused by sharp objects.

These are the different samples that can easily be tested using a bursting strength tester. If you want to know more about these lab testing instruments, then you can simply give us a call at +91 9313 140 140 or email us at info@testronixinstruments.com.