Reviewed by Anurag Mishra (Sr. Technical Consultant)

Corrugated boxes are the prime source of packaging for sensitive and perishable items. These boxes are utilized in the shipment procedures from one place to another, carrying different products that might get contaminated or broken even by minor hazards.

Corrugated boxes are used all around the globe due to their ease of packaging as well as affordability but on the contrary, their durability is not always up to the mark as they are made of corrugated sheets.

To avoid such an altercation the corrugated are assessed upon their durability before getting used in such transit and storage measures as these boxes might be dropped and tacked together to save space and easy storage. One such condition where the durability of the corrugated box is tested is during the stacking of these boxes to save space during transit or storage measures.

During this stacking period, the weight of other boxes exerts pressure, which results in the deformation of the box kept at the bottom and thus hampers the packaged item kept inside.

To curb this issue of deformation due to stacking the finest lab testing instrument manufacturers - Testronix offers a stacking simulator, called the box compression tester.

The box compression tester is a top-notch instrument, designed with extreme precision and top-quality engineering, which ensures accuracy-driven results consistently.

The simplistic operating mechanism of the instrument has gained the trust of manufacturers from different industries over the years, using corrugated boxes as prime packaging products.

The box operation tester conducts the test with absolute facile due to its ergonomic design that aids the operator in conducting the test in an expedited manner.

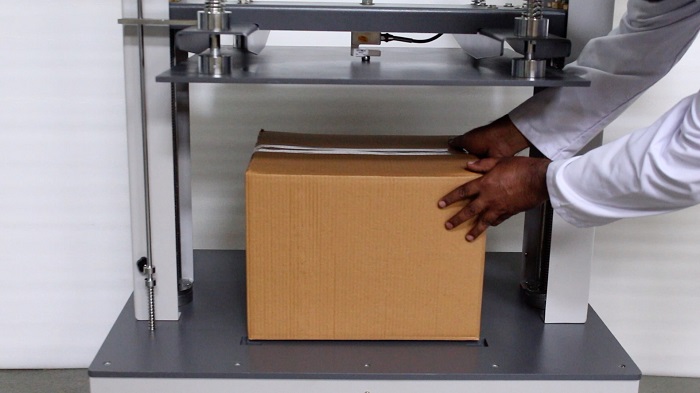

The first and foremost step to commence, the test is to position the sample at the sample positioning platform. The operator must make sure that the sample is placed between the carved-out labels.

Once the sample is positioned accurately, the operator can begin with the testing by initiating the movement of the compression plate with the control panel.

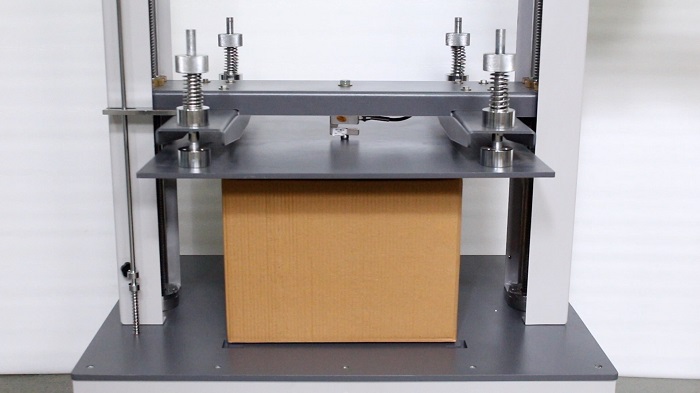

The compression plate is associated with the lead, screw at the top of the corrugated box that is going to be tested. The compression plate is equipped with a pressure assembly of 500 to 1000 KGF, which is exerted on the specimen.

The compression plate starts moving downward at a certain speed as mentioned in the guidelines of the designated standard, forcing the pressure on the corrugated box and deforming, the corrugated box after forcing the maximum pressure that the man could withstand.

The maximum load or the peak load value that the corrugated box could withstand is depicted on the microprocessor-based digital display.

The deformation that took place due to the exertion of the pressure is also indicated on the microprocessor-based digital display.

Once the testing is completed as the specimen is deformed, the comparison plate automatically comes back to its original position due to the provision of limit switches that prevent the compression plate from over traveling.

This is how the box compression tester conducts the test with absolute ease & facile. The simplistic mechanism of testing is conducted with this much smoothness due to the incorporation of immaculate features.

The box compression tester is equipped with immaculate features that the operator to achieve highly accurate and precise testing results.

The most prominent feature of the instrument that has gained the trust of manufacturers from all across industries is the inclusion of limit switches that restrict the compression plate from over traveling and causing hazards and jeopardies due to the same.

The speed of the compression plate is in compliance with designated standards i.e. 12 MM per minute. This elevates the sense of accuracy-driven results determination.

Another feature of the instrument is the incorporation of the circular lead screw that enables the smooth movement of the compression plate, both upward and downward. This box compression tester feature ensures seamless testing by minimizing the hassle.

The construction of the instrument is a feature in itself as it is constructed with the durability of mild steel material, which is coated with 7-layered powder paint that prevents rusting as well as corrosion for a longer period of time, ensuring the longevity and durability of the instrument.

All these top-notch features are responsible for seamless and hassle-free testing with such position and accuracy over and over again.

There are certain questions regarding the box compression tester that creates confusion, therefore Testronix has decided to provide answers to these questions.

To elevate the quality and enhance the durability of corrugated boxes that are used for packaging such important products & items, a manufacturer must buy box compression tester. For further Q&A’s or collection of information regarding the instrument, you can feel free to visit our website. To book the box compression tester with certain customizations as per your requirements place a call at +91 9313140140 or write to us via e-mail at info@testronixinstruments.com.

Ans. The corrugated boxes carry perishable as well as sensitive & expensive items that might get contaminated or broken due to the deformation of the box. To safeguard these items & products from contamination and breaking, it is important to check whether the corrugated box is durable enough or not.

Ans. The box compression tester is a customizable instrument offered by Testronix. The compression plate or the specimen placement platform is available in different sizes to cater to variable-sized boxes. You can reach out to the company website to ensure the sizes available.

Ans. The speed of the compression plate is slow so that the factor of momentum or speed does not hamper the durability levels of the instrument as the instrument is made with an approach of simulating stacking.