Reviewed by Anurag Mishra (Sr. Technical Consultant)

The utilization of corrugated boxes is on an increasing path because of the dependency of people on them for packaging various products into such boxes. Corrugated boxes are a very useful packaging material in the market nowadays which makes it highly important for the manufacturers of paper & packaging industry to ensure the quality of these fragile boxes. The quality is determined by analyzing the durability of such boxes against high drops that boxes might face during storage and transportation.

The Testronix Instruments has come up with a high-quality lab testing instrument for conducting such durability tests on fragile boxes called the drop tester pneumatic.

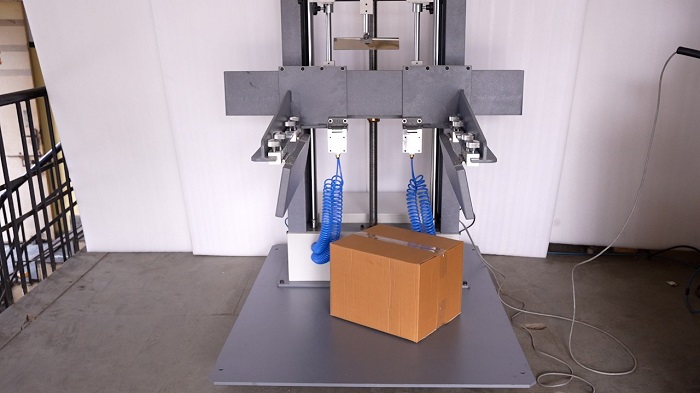

The drop tester pneumatic simulates real-life incidents of free falls that these fragile boxes experience during transportation. This lab testing instrument plays a vital role in the paper and packaging industry. The testing is done with a very simplistic technique to ensure the easy functioning of the instrument by the operator.

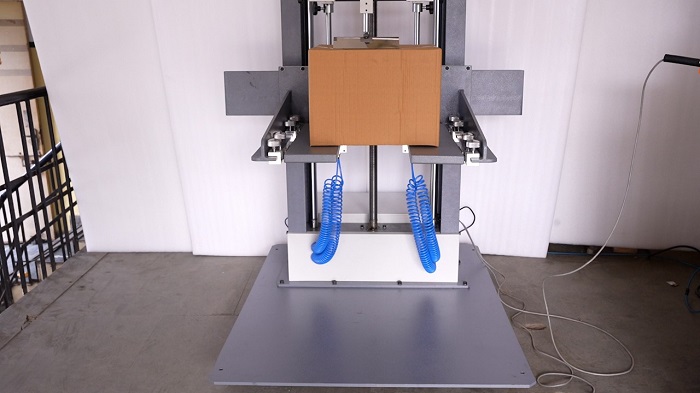

The instrument contains a dual-door platform that is pneumatically attached for the placement of the sample, once the sample is placed on the dual-door platform, the platform is adjusted to a specific height.

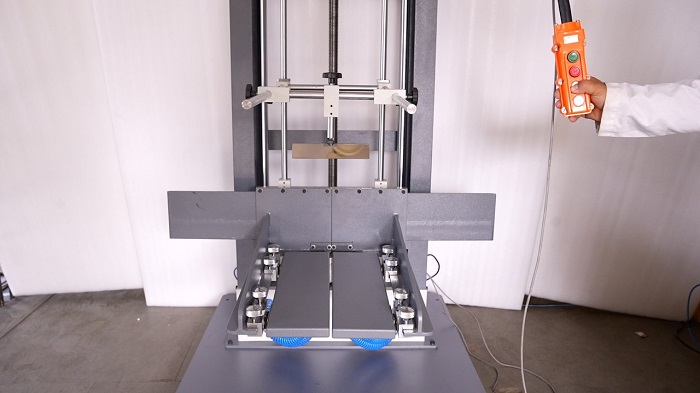

After the height designated in the standards is adjusted, the platform is opened through the pneumatic pedal or the motorized remote controller provided with the lab testing instrument.

The specimen then drops on the floor and the operator can now simply assess the deformity and the defects that took place due to the drop. The drop test machine allows the operator to conduct a critical analysis of the specimen as per the standard requirements.

The pneumatic drop tester aids the operator in conducting testing with accurate & corrective measures with no hassle at all because of its feature-enriched construction by the Testronix.

The drop test machine is powered with features to derive accuracy and keep the manufacturers of corrugated boxes a step ahead of their competitors.

The lab testing instrument is constructed with such attention to detail because of its widespread relevancy in so many industries including pharmaceuticals, textiles, FMCG & a lot more like them.

It becomes important to conduct these tests with precision to ensure customer satisfaction, hence, building brand value and reputation.

To conduct the testing with high levels of accuracy it is important to consider some factors during the installation of the packaging drop tester. Conducting the drop test under correct measures is necessary as the specimen will be carrying important products & items packed into them during storage & transportation.

Get yourself an assurance of quality manufacturing by getting your hands on a well-manufactured packaging drop tester in India. You can find answers to queries on our website or you can directly dial our number - +91 9313140140 or write to us on our e-mail handle at info@testronixinstruments.com. We will assist you with all your needs and queries.