Reviewed by Anurag Mishra (Sr. Technical Consultant)

Metal is one such material that is used in various industries to enhance the durability of various products due to its resistant properties. However, along with the strength and hard surface areas, metals have to be tested against their pliability or in other words ductility.

Manufacturers from different industries utilize metals in their production process to enhance the durability of the products but that may hamper the ductility as metals are not very flexible materials. To evaluate the ductility of these metals it becomes very important to evaluate metal sheets under flexible force application.

Similarly, in the paint industry manufacturers have to assess the ductile strength of the coating over paints to avoid cracking due to deformation and avoid any sort of visual uncertainty which may impact the decision of the final customer.

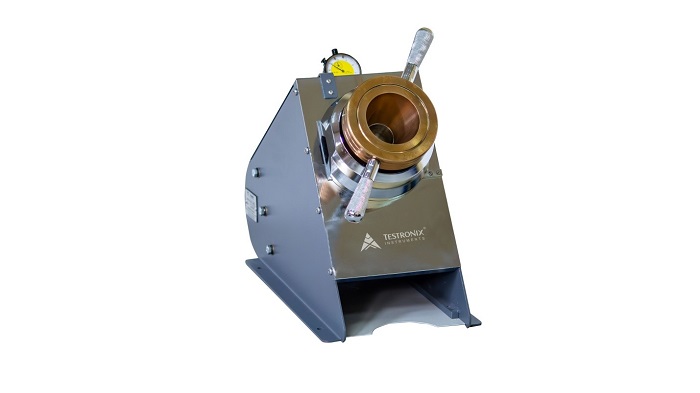

To overcome these challenges of manufacturers from the paint & metal sheet industry, the leading lab testing instrument manufacturer, Testronix has come up with a solution called the cupping machine.

The instrument is designed with extreme precision to assess & evaluate the deformity a metal sheet or paint coating can withstand before breaking or cracking respectively.

It is better to understand the functioning module of the instrument to have insightful knowledge about the same.

The instrument has an ergonomic design with a robust construction which makes the testing absolutely hassle-free and also promotes single-handed testing.

To commence with the Erichsen cupping test, the operator must make sure that the sample does not exceed the thickness of 1.8 mm.

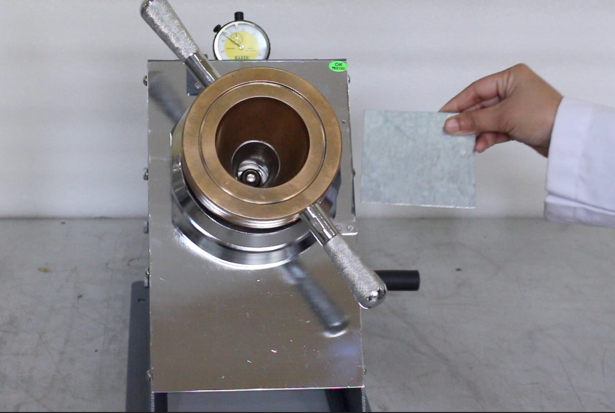

Once the sample thickness is assured, the metal sheet (sample) is placed at the clamping mechanism in front of the punch. The punch is a hard hemisphere-shaped structure.

The specimen is clamped firmly to ensure that it does not move away or slip during the testing process as it may hamper the final result. The clamping is ensured with the help of the clamping handles associated with the brass dial.

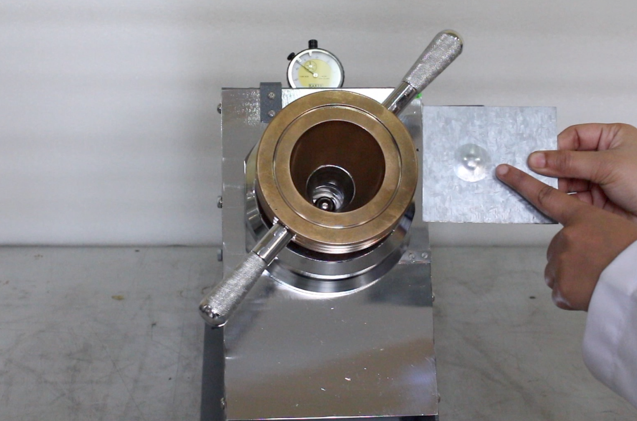

Once the specimen is firmly clamped the rotary handle is used to push the hemisphere-shaped punch forward at the specimen. After the impact with the punch followed by a continuous rotation of the rotary handle results in the further pushing of the punch, forcing the specimen to deform and after a point crack or break.

When the punch is pushed further enough to form cracking or breaking into the specimen, the deformation value is recorded from the deformity dial gauge. The dial gauge is associated with the top of the instrument, enabling the operator to simply record the results.

The instrument determines the ductility of metals and paint coatings over metal sheets with absolute ease due to certain features incorporated along with its robust construction.

The Erichsen cupping test is conducted with this much ease due to the incorporation of certain features that enhance the working as well as the durability of the instrument.

The first & foremost feature of the instrument is the robust construction itself. The instrument is made with a combination of brass, stainless steel, and mild steel that is coated with a 7-layered powder paint to avoid corrosion for a long period of time.

The cupping tester is also equipped with wheel-type clamping handles for easy and firm clamping with a rugged surface of the specimen that will ensure no movement of the specimen at all, allowing the manufacturer to achieve the desired results.

The instrument also offers a hemispherically structured punch to ensure maximum deformation with minimal human effort, enhancing the testing measures undertaken by the operator.

The dial gauge associated with the top of the instrument allows the operator to record precise results and keep track of data with absolute facile.

All these features combine together and provide a perfect balance to the instrument in attaining accurate results without any sort of external factors affecting the desired output.

If you also want to assess the ductility or pliability of metal sheets or paint coatings, you can get your hands on the top-notch lab testing instrument called the cupping machine. The instrument is designed with absolute precision and futuristic engineering standards to aid manufacturers of the metal sheet as well as the paint industry.

You can step up your manufacturing process with the cupping machine right away. Do not wait any longer and place an order by reaching us through our website. You can also place an order via phone call or e-mail on the below-mentioned information:

Testronix is one of the finest lab testing instruments in the country. The company aims to provide you with the finest & most futuristic lab testing equipment to keep you a step ahead of the competition.