Reviewed by Anurag Mishra (Sr. Technical Consultant)

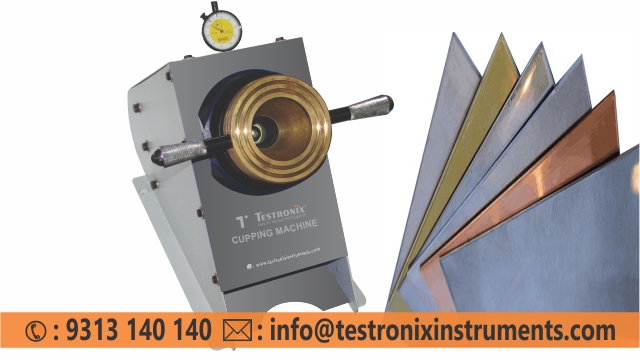

Testronix Instruments brings a unique testing machine for metal sheets and plastic. The Cupping Machine by the company is an exclusive tool that helps to determine the ductility of the material like metal and plastics. By the word ductility, we mean the stage of deformation before a breakout. To ensure the quality of the painted or coated sheet in terms of efficiency and durability, the cupping test provides an accurate result.

The Cupping Machine has an application in the automobile industry that measures the durability and quality against dents, scratching, and cracking, etc. Testronix ensures the best quality of the testing instrument through in-house manufacturing. You will get the best metal sheet testing machine with cutting-edge technology at reasonable rates. The cupping test provides reliable results on testing the varnish in metal sheets, adhesion, hardness and permeability of coating or paint, etc.

Testronix presents Cupping Machine which has high quality and is designed as per global standards and available with the certifications like ISO: 10175 (Part I); 1993 & ISO 8490: 1986, ISO 1520:2006. Get the best services in lab testing instruments at the best competitive prices.

What Is The Working Principle of Cupping Testing Machine?

The working principle of this testing machine is very simple. In this test, the metal sheet is placed in the machine, and force is applied by a hemispherical punch into the sheet till a crack appears on it. At the point of crack, the ductility is counted. It is generally counted as the depth of the cup where the ductile metal will result in a deeper indent with a rough shape of the cup. On the other hand, the harder metal will result in a fine shape of the cup with less depth. As per the global standards, to determine the ductility and performance of the cupping test, the thickness of the metallic sheet is important which should be about 1mm. Here is how it works.

The investment in quality testing is always rewarding. Therefore, updating your manufacturing units with reliable testing instruments would assure the best results.

Testronix – The Best Company For Testing Instruments in India

Testronix is one of the most trusted and reliable companies in India that serves hundreds of industries through quality-assured testing solutions at reasonable results. To meet the market demand for various lab testing instruments, the company strives to bring hi-tech machines that are affordable in rates, precise in design, and best in quality material. The company complies with the global standards, hence assures quality for better results.Connect with our experts to know anything about any testing instruments. We are available at +91-9313 140 140. Also, you can mail us your query at info@testronixinstruments.com.