Reviewed by Anurag Mishra (Sr. Technical Consultant)

The cupping tester is a very unique and precisely manufactured lab testing instrument for application in the paint as well as the metal sheet manufacturing industry. It is extremely important to measure the ductility, and durability of the metal sheets and the paint coatings used on certain products to ensure sustainability for a longer period of time.

The cupping tester works on a very simplistic and expeditious mechanism of measuring the metal formation and ductile strength called the Erichsen cupping test. This cupping testing instrument is an extremely cost-efficient measure to indicate the durability, ductile & tensile strength of the metal sheet and the paint coating.

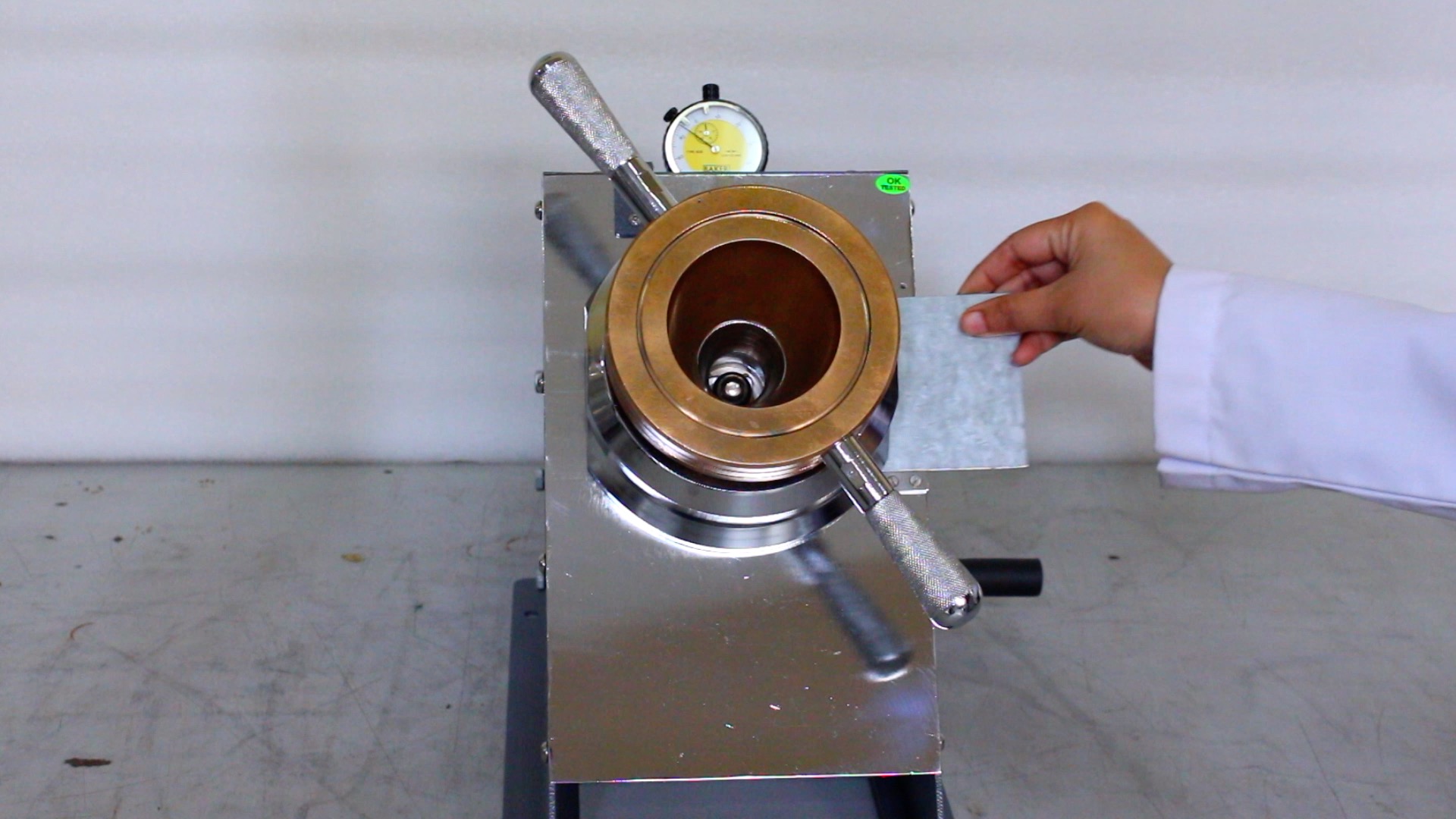

The cupping tester is offered with a dedicated specimen holding slot, where the manufacturer of the specimen can place the material. Before placing the specimen, make sure that the thickness of the specimen should not exceed 1.8mm in order to derive accurate results.

Once the respective specimen is placed in the holding slot, the specimen is then clamped with the help of the clamping holders. It is vital to clamp the specimen firmly to avoid movement of the metal sheet (painted/non-painted) while performing the test.

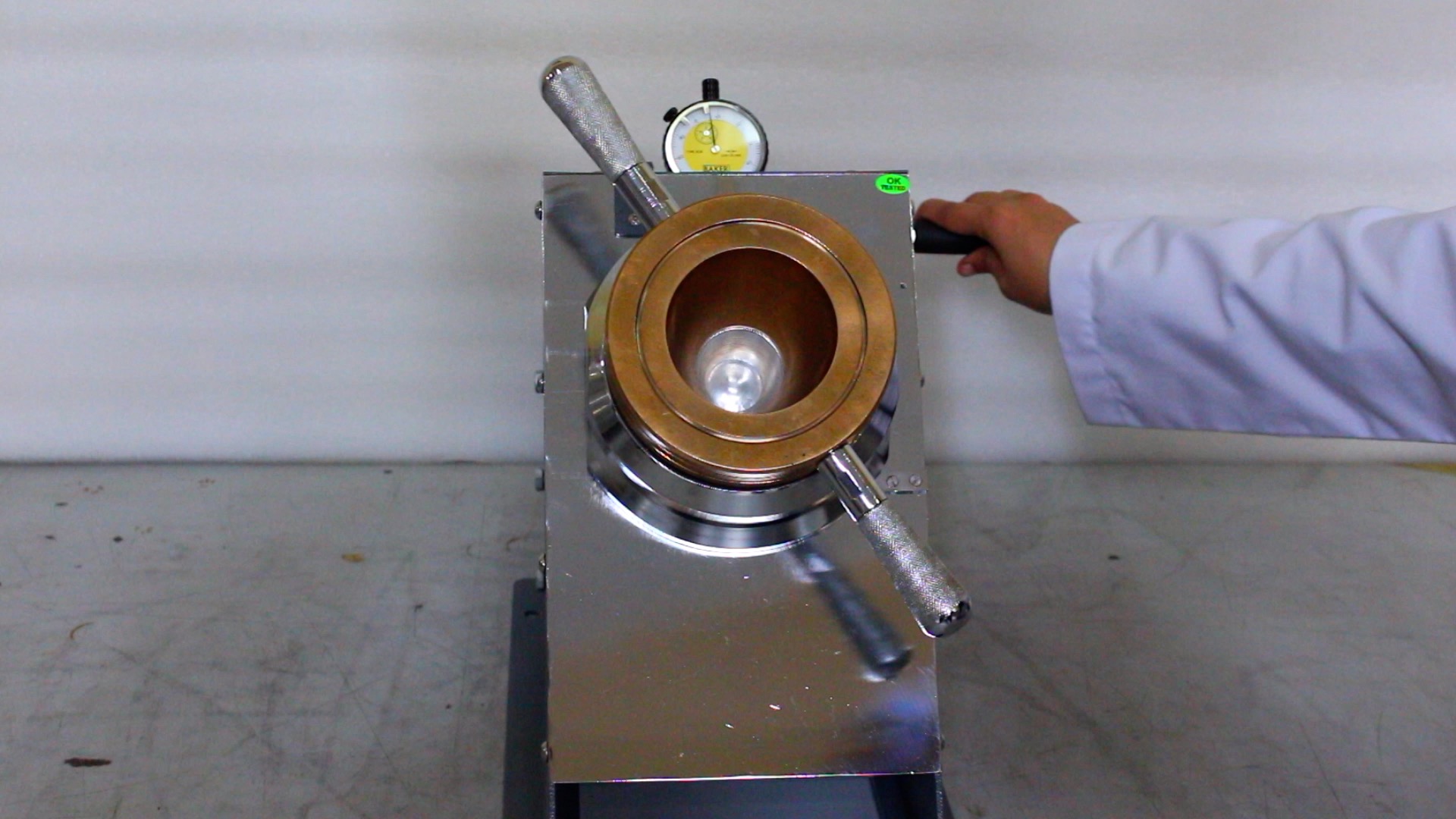

After the sample placement, the operator is required to rotate the side-wheel handle attached. The rotation of the side wheel handle will push the hemisphere-like structure called the punch upwards, penetrating the sample.

Once the sample reaches the maximum pressure it can withstand as per its durability & ductile strength, the punch penetrates through it leaving the sample broken or deformed.

The results of the test are simply measured by a dial gauge associated at the top of the cupping tester showcasing Erichsen cupping test results. The results on the dial gauge are indicated in the units of mm and micron to ensure accuracy & precision.

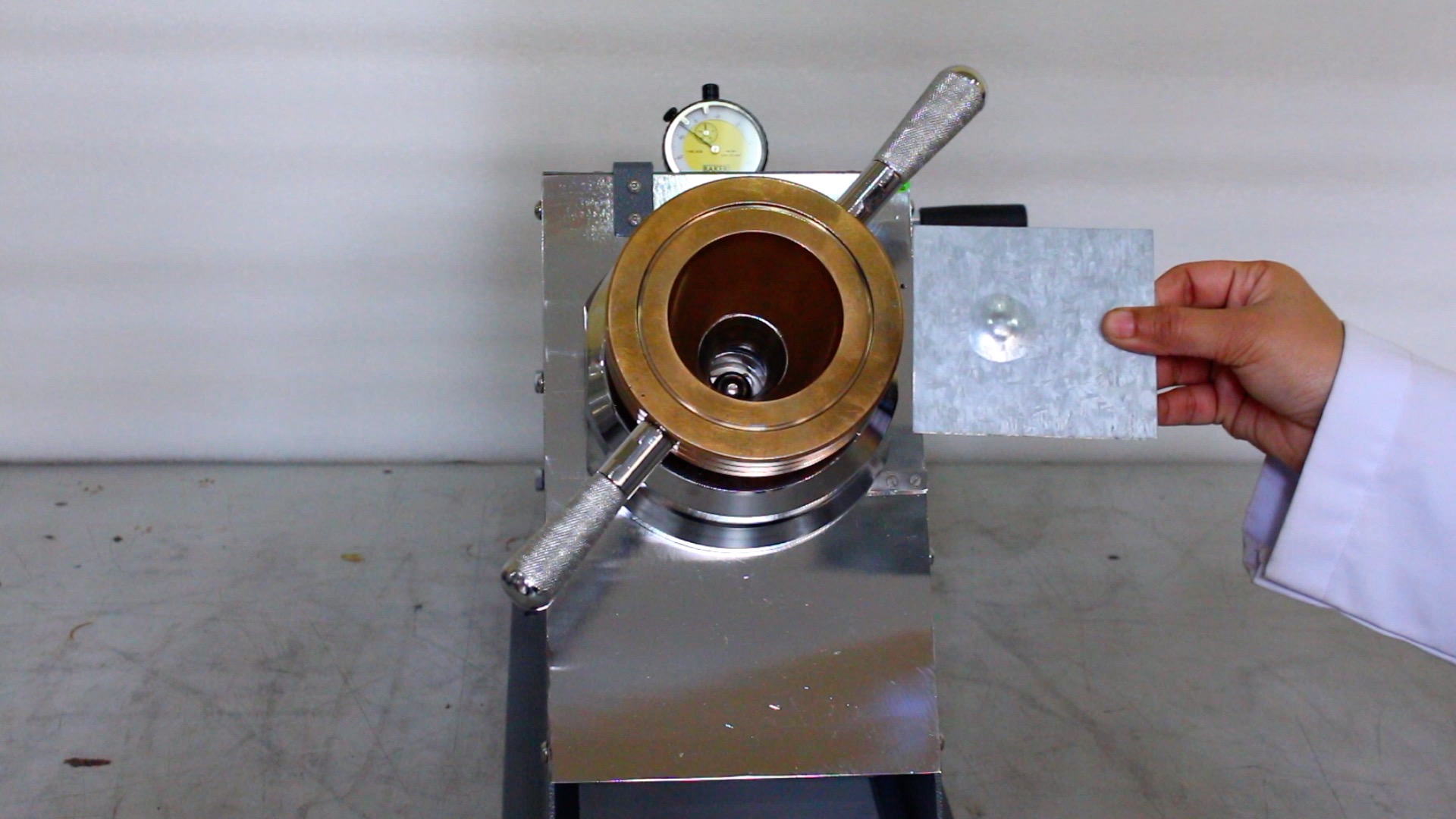

Once the test is completed make sure to take the specimen out of the sample holder by first, moving the rotating wheel anti-clockwise, resulting the punch going back to its original position. Once the punch is back to the original position, move the side handle anti-clockwise to loosen up the clamping and then you can simply take the sample out of the cupping testing machine.

The instrument is a very uniquely manufactured by Testronix Testing Instruments, making the instrument extremely feature-loaded to simplify its functioning and assist the operator in acquiring accurate results repeatedly.

The construction of the cupping testing machine ensures the sturdiness and durability of the instrument. The use of stainless-steel material makes the machinery corrosion-free and also provides longevity of usage.

The dial gauge association at the top enables the operator to easily look at the results of the performed test without any hustling. This ensures accuracy while recording the results of a test.

The brass housing manufacturing and placing make the clamping very easy and firm to ensure that there is no movement of the specimen while the test is under process.

The machine also offers a rotating wheel, which is operated manually while performing the test, ensuring smooth and resilient movement of the punch. This is a necessary feature to become the best cupping tester for a manufacturer.

The cupping testing machine is a product assisting the manufacturers from the metal sheet and paint coating industry to identify the durability and ductile strength of their manufactured specimen. The working of the machinery is made extremely simplistic allowing single-handed operations with a dial gauge attached at the top of the machinery to assist the operator read & record the results accurately.

The manufacturing along with the feature-enriched design by the Testronix Testing Instruments easily makes the machine the best cupping tester currently available in the market.

If you also want to accurately measure the ductility as well as the durability of your coated or non-coated metal sheets, you can simply visit our website. To get an answer to your queries regarding the product, feel free to contact us via phone at +91 9313140140 or you can e-mail us at info@testronixistruments.com. We will be delighted to assist and help you find the best cupping tester available in the market.