Reviewed by Anurag Mishra (Sr. Technical Consultant)

The use of paper & related packaging material has gone a notch higher since the banning of plastic packaging products to safeguard the deterioration of the environment and especially the oceans thus the water life.

With the increase in the need for manufacturing paper products, paper packaging materials have also developed into variable packaging as well as useful products.

One such example of paper replacing plastics due to their adverse impact on the environment is the use of paper straws rather than plastic straws as they were impacting the lives of turtles and many other water animals & mammals as they cannot be decomposed or recycled.

Since the paper material has gained the trust of the market, there are numerous testing standards that a paper product has to satisfy to live up to the expectations of the consumer and serve them the same hassle-free experience as before.

Due to the absorption of moisture and getting utilized closely into the products & packaging materials like glasses, food packing containers, etc. the rupturing tendency of papers increases and thus it can hamper the quality of the item packed inside.

Therefore, manufacturers of paper & packaging materials undergo rigorous testing measures to assess the rupturing tendency or the bursting strength of the paper.

To aid manufacturers in evaluating the bursting strength of papers and the rupturing tendency, the finest lab testing manufacturers in the country – Testronix have come up with an outstanding lab testing instrument called the bursting strength tester.

The long-lasting R&D resulted in the construction of the bursting strength tester. The instrument is manufactured to work on the principle of hydrostatic mechanism and serve pinpoint accuracy to the manufacturers.

The instrument is optimized with a safe & smooth working process to elevate the standards of testing.

The lab testing instrument is designed with utmost precision to serve the needs of manufacturers in achieving high levels of accuracy & also serving the consumers with a product that complies with standard guidelines thus carrying an assurance of quality.

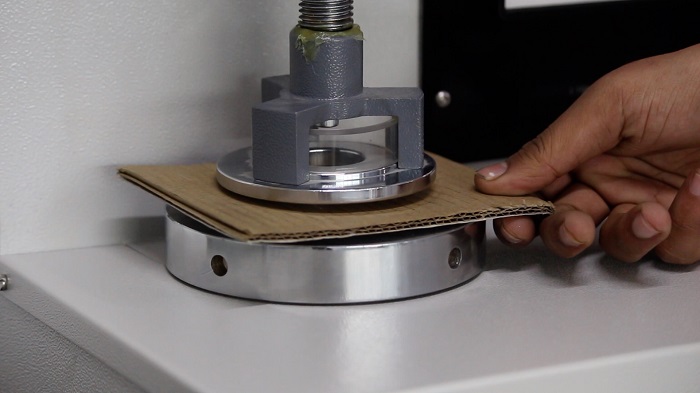

The working process of the instrument starts with the manufacturer assessing the right specimen and placing it between the clampers of the instrument integrated right above the diaphragm.

After lacing the sample, the operator must use the rotary wheel to firmly clamp the specimen and ensure no or minimal movement during the testing process. The instrument is clamped above the diaphragm to ensure accurate testing results on the movement of the diaphragm.

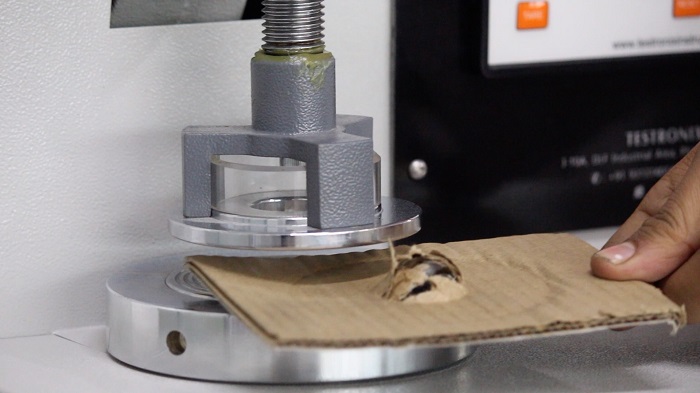

The operator can now begin with the testing which initiates the hydrostatic working mechanism of the instrument that takes place below the diaphragm as the glycerine acts as a medium of travel to exert pressure on the diaphragm.

Since the diaphragm is constructed out of neoprene rubbers, the diaphragm expands due to elongation properties on exerting pressure. The pressure exerted on the diaphragm expands it which results in the diaphragm exerting bursting force on the specimen clamped above it.

The pressure exerted by the diaphragm is indicated on the microprocessor-based digital display of the instrument. The specimen withstands the pressure as per its rupturing resistance but bursts after the pinnacle is reached and the maximum load it can withstand is indicated on the digital display as the bursting strength of the specimen.

This is how the manufacturer of a paper & packaging material can identify the bursting strength of the material utilized in the manufacturing process. This also allows the manufacturer to measure whether the instrument is standard complied or not and in the case of discrepancies, the operator can identify them and fix them before the products are out for consumption by the customer or consumer.

The burst testing machine offers numerous fine-quality attributes that aid manufacturers in performing the bursting strength test with a lot more facile and with minimal hassle for determining accurate testing measures.

The burst test machine is made with the goal of determining the rupturing resistance of paper & packaging material as the demand for the use of paper has increased rapidly since the limitations are imposed on plastic materials. Assessing the bursting strength of paper has thus become extremely necessary for manufacturers. There are certain features incorporated into the instrument that help the manufacturer reach the test results superficially but accurately at the same time.

The most prominent feature or attribute of the bursting strength tester is the incorporation of neoprene rubber for carving the diaphragm out. The neoprene rubber is a high-quality rubber material that does not lose or react to certain climatic conditions and thus allows the bursting tester manufacturer to supply the instrument all across the globe.

Another high-end attribute instilled within the bursting strength tester is the use of a rotary wheel for the clamping of the sample over the diaphragm. The rotary wheel encourages single-handed testing measures and also streamlines the clamping process of a specimen.

The instrument is also offered with a top-notch microprocessor-based digital display that indicates the test results, allowing the operator to keep track of the results. tracking results also becomes easy due to the memory hold button integrated into the control panel that enables the instrument to record up to 9 test results.

The instrument enhances the quality standards as the bursting tester manufacturer assists the operator in performing in-built calibration as it is equipped with two verification foils for completing the calibration task.

To attain maximum accuracy in determining the bursting strength & bursting factor of a specimen, you can get your hands on the top-notch bursting test machine.

For more information regarding the lab testing instrument’s price & specifications, you can visit our website right now. To place an order for the bursting strength tester, do not wait any further and give us a call at +91 9313140140 or e-mail us your requirements & customizations at info@testronixinstruments.com.