Reviewed by Anurag Mishra (Sr. Technical Consultant)

It is essential to check the leakage of the bottles to avoid damage to the entire production line. The bottles should be checked against leakage to maintain zero rejection rates. The vacuum testing machine makes sure that there is no spoilage or contamination due to leakage of the bottles.

When the bottles are exposed to the vacuum leak test, then its packaging quality is assessed to avoid any integrity issues with the product and the right product is delivered to the customers. Hence with the Testronix vacuum leak tester for bottles, the quality of the bottles can be checked and any sort of leaks can be detected. This test is mainly used for PET bottles.

When the bottle is infiltrated with the air, leakage occurs and the quality of the PET bottles is affected. The right seal of the bottles is essential for delivery of the reliable products to the customers.

By subjecting the bottles to the vacuum leak tests, manufacturers can detect the defects and rectify them accordingly so that they can ensure customer satisfaction. Testronix Testing equipment complies with set standards so that accurate results can be attained. By performing this test, the bottles will be free of leakages.

To maintain the quality of the products, these tests are conducted. The pros of performing this test are:

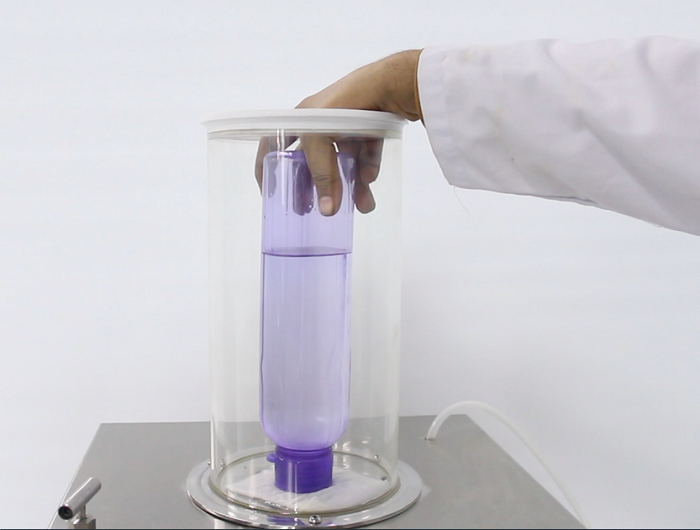

If there is any suspicion for the leakage in the bottles, then the vacuum leakage test should be performed to avoid any sort of leakage. The steps to perform the vacuum leak test are:

To ensure the equipment's long life, you can follow the steps mentioned below:

By using a vacuum leak tester for bottles, you can ensure that there is no leakage in the bottles. Furthermore, it will minimize the chances of spillage or contamination in the production belt which will save the belt from getting damaged.

When you make sure that the top quality products are delivered to the customers without any leakage, then it will help you attain more customers and enhance the brand image as well. It will in return increase the revenues for the company. It will also increase brand awareness and more customers will come to the company which will in return improve the brand identity.

This lab equipment detects any kind of imperfections in the products by checking them against leakage and it is an essential quality testing instrument that every bottle manufacturer should possess. If there is any leakage in the specimen, then after placing it in the vacuum it will shrink and predict the leakage. Using Testronix vacuum leak tester for bottles is considered to be the easiest way to detect the vacuum leaks.

It ensures the packaging of the products is intact so that no damage to the products occurs while they are in transit. It makes the entire process cost-efficient as there are lower rejection rates. It saves time and money as well since customers accept the orders in one go and time for return or replacement is saved. Furthermore, the process becomes cost-efficient as well since manufacturers do not receive back any products and the delivery charges of sending the products again to the customers are also saved.

A vacuum leak tester for bottles is essential to check the bottles against any sort of leakage. Moreover, after creating the vacuum inside the bottles, manufacturers can easily determine the areas from where air is leaking out.

Testronix being an established manufacturer of lab equipment and vacuum leak tester for bottles is one of them. This lab equipment can be used hassle-free and comes with a microprocessor digital display as well. Secondly, it comes with a vacuum pump as well to ensure consistent pressure throughout the chamber. It has leak proof chamber as well to record reliable results. Importance of conducting the vacuum leak test on PET bottles will not only help manufacturers in assessing the quality but also help them to ensure that accurate product will be delivered to the customers.

This highly featured equipment has a vacuum sensor, a control panel, and easy-to-operate functions that ensure the quality of the PET bottles.

The vacuum leak tester for the bottles has been discussed in detail till now. Testronix vacuum leak tester is highly advanced and checks the quality of the bottles. When bottles are checked against any kind of leakage, the chances of contamination and spillage are reduced. You can read more on how to test your bottles against vacuum leaks.

We at Testronix Testing Instrument manufacture the best quality vacuum leak tester for bottles. To gain an understanding of Testronix products, customers can give a call at +91-9313140140 or drop an e-mail at info@testronixinstruments.com. Our team of technical operators will assist you.