Reviewed by Anurag Mishra (Sr. Technical Consultant)

GSM is perhaps one of the most important qualities for various materials, for example, paper, packaging sheets and others. The packaging is the main perspective that is necessary when it comes to the quality of the material being tested. When products are being manufactured in an organization, the manufacturers are worried about the quality. For that, there are various types of value tests that are performed on the items to guarantee durability. If you want to calculate the GSM of paper and other related materials, then you must use a Testronix GSM round cutter and weighing balance.

To supply the items without imperfection, it is fundamental that the manufacturing of the items is picked astutely. The materials that are utilized for the packaging of items should be of the best quality and should have enough strength that is needed to guarantee that the packaging of the items will stay flawless. The packaging materials chiefly utilized in the ventures incorporate paper, cardboard, ridged boxes, and textures.

The packaging materials can guarantee that the item is conveyed to the customers in the most secure way and there can't be any danger to the wellbeing of the items. It is likewise used in Paper and Packaging Testing Instruments.

The GSM of a paper can be related to the strength of the materials. The GSM is the proportion of the weight of a material for every square meter region of that material. This amount is generally utilized in a wide range of enterprises to decide the actual characteristics, for example, strength and development of any material. Various materials have distinctive GSM and furthermore unique meanings of GSM for various materials.

GSM of a paper provides basic data about its attributes. Paper is accessible in the market with various sizes, characteristics and qualities. The utilization of paper is common in numerous businesses for an assortment of uses. It is utilized as fixed in schools and workplaces. It is the most fundamental asset for the printing business too. It is additionally utilized for wrapping and packaging various items in various businesses. GSM Weighing balance can be used to calculate the GSM of the machine and ensure that users will get accurate lab testing results.

Because of such vital applications, the nature of the paper is vital and the producers should remember that the characteristics of the paper they are providing to the business sectors are critical. Quite possibly the main viewpoint while dissecting the nature of paper is the GSM of paper.

Once the material is cut using a paper GSM round cutter, it is important for the manufacturers to weigh this sample using a weighing balance.

The GSM of a paper is given by estimating the heaviness of the 100 sq. meter test of the paper being dissected. The GSM of the paper can help the makers in choosing the nature of the items and henceforth choosing their cost. As the GSM straightforwardly affects the strength and readiness of the paper, the makers should guarantee that the privileged GSM of the paper is fused and certain proposed uses.

Cardboard is another normally utilized material in numerous businesses. It is utilized in craftsmanship classes, schools and colleges in various applications and tasks. They are likewise utilized as a significant packaging material in the packaging businesses just as different enterprises. Cardboards are additionally utilized for making cylinders and bases for any rolls. Cardboard is a material that is produced using reused paper called paper. These liners are additionally produced using reused paper or reused old cardboard.

As these cardboards are produced using reused paper, there are a lot of chances that their quality is debased during assembling if there are any mistakes in counts or any human blunder. Also, these cardboards are utilized for basic applications, for example, packaging items.

This is the reason the producers need to guarantee the best nature of cardboard by testing their solidarity and honesty. There are numerous components that can influence the quality and strength of the cardboard and thus should be tried altogether.

Weight per M2= (Weight of test in grams per cm2) X 10000/Area of test in cm2

You can easily calculate the GSM of paper and ensure the quality of materials to be delivered to the customers.

Ridged boxes are the most broadly utilized alternatives with regard to packaging boxes. The ridged boxes are utilized for as they offer the best strength and security to the items that will be bundled in them. They are equipped to bear the hefty forces that they are subjected to during the transportation of the items. The creased boxes are built from folded sheets that are set up by putting one layer of sheet on another.

The GSM of the creased sheet has a major part in choosing the strength of the case. Moreover, the GSM is additionally a significant factor that can be useful in finding the bursting strength and bursting component of the layered sheets which is further extremely accommodating in deciding the general strength of the items. The producers can have the ideal strength of the sheets by modifying the number of layers in a folded sheet and henceforth can without much of a stretch control the strength by rolling out required improvements in the assembling cycle.

This aids the producers in guaranteeing that the correct strength folded box is utilized for the correct application. There is no sense in utilizing an extremely high-strength folded box for an application where exceptionally low strength is needed as it can cause misfortunes. Thus, the estimation of GSM can be useful in identifying the quality required in various industries

Textile materials, for example, Fabrics are likewise utilized for various applications, for example, attire, modern fabrics, tents, parachutes, etc. Additionally, the strength of the textures is estimated so they can endure upsetting conditions, for example, parachutes and mechanical garments. The GSM of the textures likewise significantly affects the quality and strength of the textures that are utilized in various applications. With regards to handling and dying of the textures, the GSM computation of the textures is significant in choosing the cycles and methods that are needed to prepare the textures for use. The dying of textures is done based on the GSM as it gives the measure of colours and different synthetic substances that are expected to get the proposed results. You can read more on how you can easily calculate the GSM of textiles with the help of this quality testing equipment.

As the GSM estimation of any material is easily identified with it is quality and actual characteristics; it turns out to be vital for the makers of such materials to guarantee that they are equipped for computing the GSM of a material with extraordinary exactness.

This is the reason, the manufacturers should test the GSM of any material with extraordinary alert and precision. In order to calculate the GSM accurately, there is a requirement of cutting a piece of sample to be measured with the dimensions of 10cm X 10cm.

This gives you a piece of 100 sq. cm. of the sample. Measure the weight of the pieces cut from the sample. Now the weight obtained is the weight of the sample per 100 sq. centimetres. In order to convert it to per square meter, you need to multiply the obtained weight of the specimen by 100. This will give you the weight of the sample per sq. meter. This gives you the GSM of the sample easily.

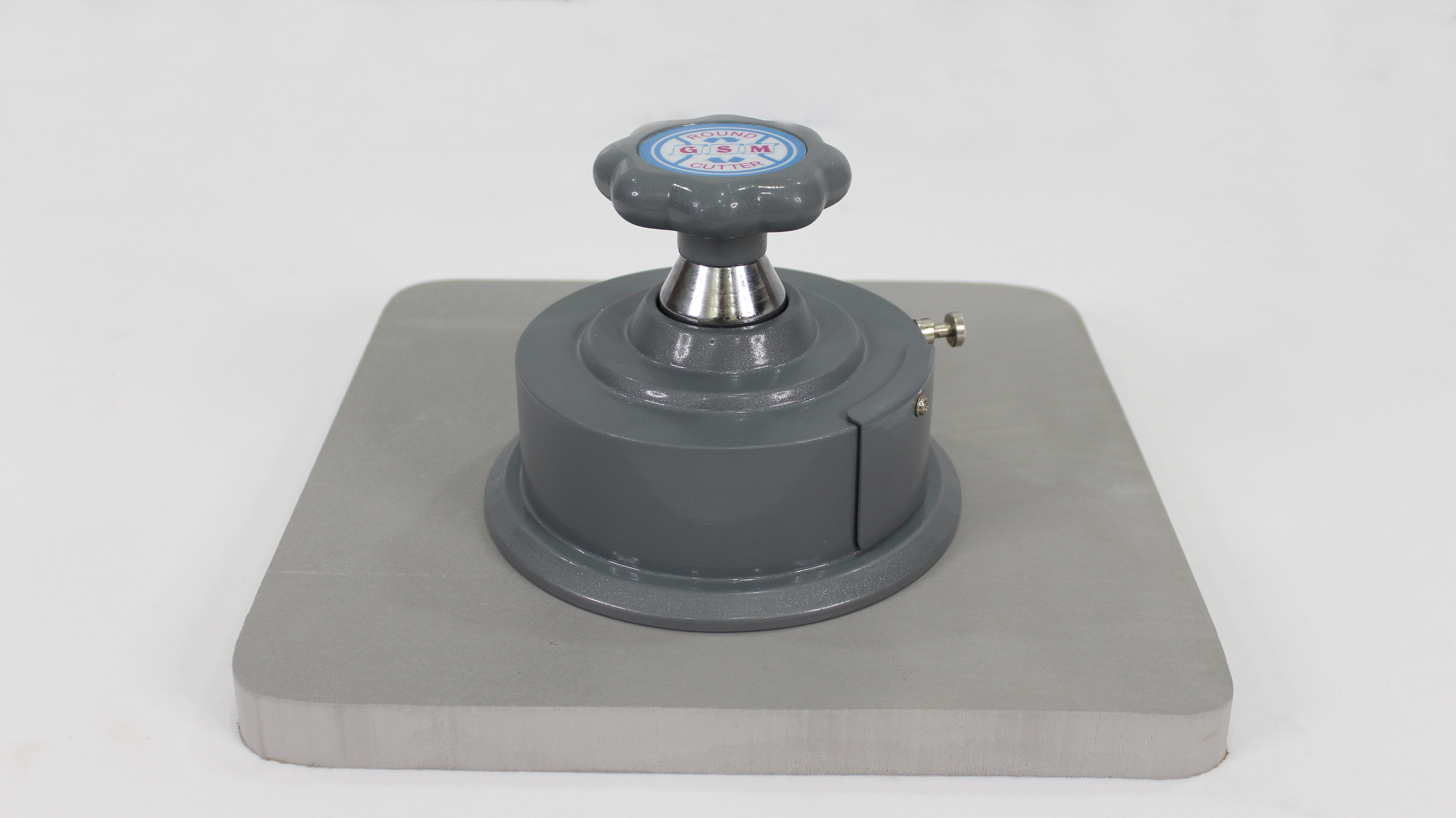

The GSM is estimated utilizing a few apparatuses so that there is 100% accuracy. As we examined, any slight mistake in the count of GSM can prompt radical changes in the properties of the material. The GSM cutter is the device that is utilized for cutting a round sheet from the example to be estimated.

This sheet has an accurate territory of 100 cm square. The GSM shaper has sharp cutting edges that make it simple. This round sheet cut structure is gauged which gives the heaviness of the material per 100sq cm. At the point when the weight is multiplied by 100, it gives the weight of the material per sq. meter which is the GSM estimation of the material being tried.

Testronix is perhaps the Best GSM round cutter manufacturer and supplier that offers a packaged unit including a GSM round shaper and a GSM weighing balance. The GSM round cutter offered by Testronix is a high-quality instrument to be utilized for measuring the GSM.

For more information regarding the packaging testing instruments manufactured by Testronix contact us at +91-9313 140 140 or email us at info@testronixinstruments.com. Our team of experts will let you know anything you require.