Reviewed by Anurag Mishra (Sr. Technical Consultant)

Pharmaceutical industry utilizes the power of colours very carefully. It is believed that colour of medication impacts the psychology of the patient and help them in speedy healing and recovery. Apart from this, the colour of medicines is coded in a way so that patient can take his prescription conveniently. People with chronic illness often jumble up their medicine and create health hazards for themselves. This is increasing the unwanted health issues and mortality rates.

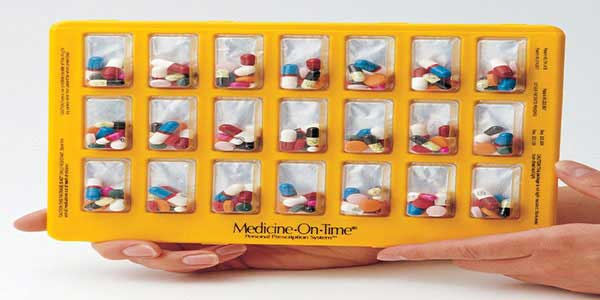

This is why health organisations are rolling out standards to standardize the packing process. And, it is mandatory for the pharma companies to adhere to these practices. Medicines for chronic illnesses are packed with day, date and time. This helps the consumer to take right medicine at right time. This is a very important step in safety and effectiveness of the drug consumption.

Why is Color Coding Important?

The common reason that confuses the patient is the similar appearance of the tablet. However, capsules are now available in coloured patterns. This is why, patients are unable to differentiate the drugs and may take the wrong dose at a wrong time, especially in over the counter drugs. Old aged patients are the prime sufferers of the incorrect prescription.

Colour coding plays a crucial part in generating indications for correct dosage and helping the patients in taking their medicines as per the prescription. Some pharma companies have already incorporated colour checkers to implement this strategy and calendarize their dosage and schedule. Marking them efficiently can easy the adherence to the prescription.

Use of Colour Measurement Instruments

Not only the colour of medicines, the colour of packing is also a major factor in misunderstanding. The technique of colouration is successful to such an extent. If the packings are coded with colour and schedule, it will leave a stamp and train the brain to do as prescribed.

Colour measurement instruments like spectrophotometer and colourimeters are largely used to keep the consistency in the production line, be it paper, plastic or medicine itself. These devices are highly capable of highlighting even the tiniest of the difference discrepancy in the packing. It actually quantifies the data and alerts the quality managers whenever there is a colour shift in accordance with the human tolerance to the change. These colour checkers detect any colour defect in the packaging prior to roll out in the market. They help a lot in managing and maintain the quality of the final product.