Reviewed by Anurag Mishra (Sr. Technical Consultant)

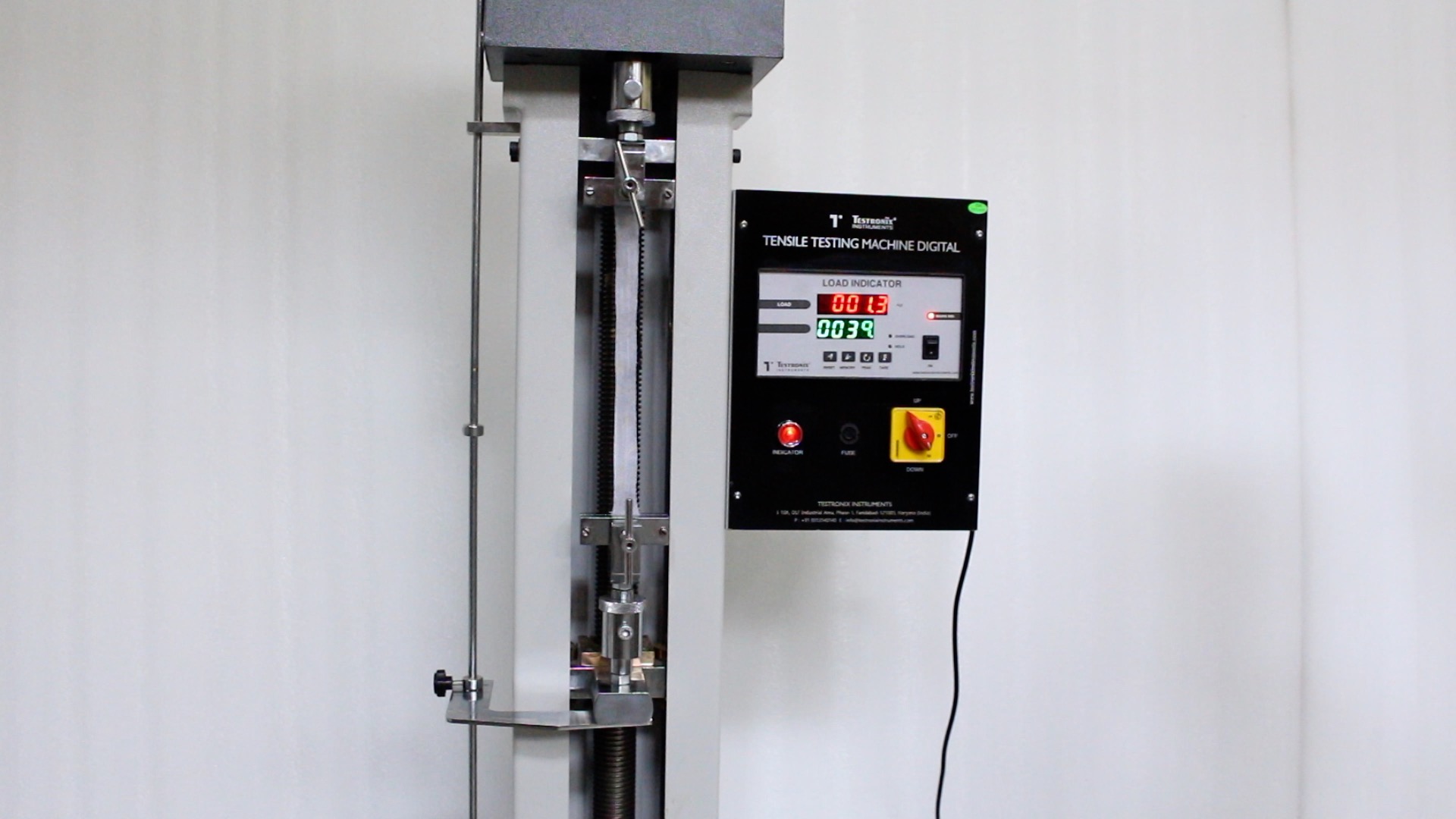

Tensile testing machines play a critical role in materials testing, providing essential data on the mechanical properties of materials under various loading conditions. To ensure the accuracy and reliability of the results, regular calibration of these machines is imperative.

Calibration is the process of verifying and adjusting the accuracy of a testing instrument to match a known or standard value. In the context of tensile testing machines, calibration is vital for maintaining the precision required in measuring forces, stresses, and strains. The frequency of calibration and the calibration process itself are key aspects that contribute to the consistent performance of these machines.

Testronix is the most trusted tensile tester manufacturer and designs this quality testing equipment with highly efficient features.

In this blog, we will explore how often tensile testing machines typically need calibration and delve into the essential steps involved in the calibration process. Understanding these aspects is fundamental for laboratories and industries relying on accurate material testing for quality assurance and research purposes.

Tensile strength testing holds paramount importance across diverse industries, serving as a fundamental metric to evaluate the mechanical properties of materials under tension. This crucial test provides valuable insights into a material's ability to withstand axial forces, offering a comprehensive understanding of its durability, flexibility, and overall structural integrity. Here's a closer look at the significance of tensile strength testing in various industries:

In manufacturing, knowledge of a material's tensile strength is indispensable for designing and producing components with the required structural strength. This ensures that products meet quality standards and can endure the stresses they may encounter during their lifecycle.

Tensile strength testing is vital in the construction industry, where materials such as steel, concrete, and various alloys are subjected to substantial loads. Understanding tensile strength helps engineers and architects design structures that can withstand forces like wind, seismic activity, and dynamic loads.

Automotive components, ranging from chassis elements to critical engine parts, undergo tensile strength testing to ensure they can endure the diverse and often harsh conditions experienced on the road. This is crucial for manufacturing vehicles that are safe, reliable, and durable. You can also read about the importance of tensile testing in metals.

In the aerospace industry, where materials are exposed to extreme conditions, tensile strength testing is imperative. Aircraft components must withstand forces during takeoff, flight, and landing, making this test essential for ensuring the structural integrity of materials used in aerospace engineering.

Researchers in material science rely on tensile strength testing to explore and understand the properties of new materials. This aids in the development of innovative materials with enhanced tensile strength for various applications, from consumer products to industrial processes.

Tensile strength is a critical parameter in the textile industry, ensuring that fabrics and fibres meet specific standards for durability and performance. This testing helps manufacturers produce textiles that can withstand the stresses encountered in their intended applications, such as apparel or industrial textiles.

In the medical field, materials used in implants, medical devices, and prosthetics undergo tensile strength testing to ensure they can withstand the physiological forces they may encounter within the human body.

In summary, tensile strength testing serves as a linchpin in ensuring the reliability and safety of materials and products across a spectrum of industries. Its application extends from the manufacturing floor to research laboratories, playing a pivotal role in the development, quality control, and innovation of materials that shape our modern world.

You can easily perform tension testing on materials with the help of Testronix tensile strength testing machine.

Calibration serves as a vital process in ensuring the accuracy and reliability of tensile testing machines, which play a pivotal role in determining the mechanical properties of materials across various industries. From assessing strength and elasticity to examining ductility, these machines provide crucial insights that influence product quality and safety.

In essence, calibration is the practice of confirming that a tensile testing machine operates within defined parameters, yielding precise and trustworthy results. The significance of regular calibration in this context is multifaceted:

Calibration stands as a cornerstone for guaranteeing that the measurements delivered by the machine align with accuracy. Without adequate calibration, there is a potential for inaccurate test outcomes, posing a risk of reaching flawed conclusions regarding the properties of the tested material. In industries where strict adherence to safety and performance standards is imperative, the precision of results becomes a non-negotiable factor.

Various industries impose regulations mandating regular calibration of measuring equipment, and tensile testing machines are no exception. For instance, the ISO 9001 certification necessitates annual calibration of all measuring equipment used in manufacturing processes. Non-compliance with these standards can result in penalties and legal repercussions, emphasizing the critical role of calibration in maintaining industry compliance.

The routine calibration of a tensile testing machine instils confidence in its consistent and accurate performance over time. This confidence is essential for professionals relying on the machine's output to make informed decisions about material properties. Knowing that the machine is functioning correctly enhances the reliability of the test results, fostering trust in the overall testing process.

In summary, the importance of calibration for tensile testing machines extends beyond mere technicality; it is a linchpin for ensuring the reliability, accuracy, and compliance of the results obtained. As this testing machine continues to be integral across diverse industries, the assurance of precise measurements through calibration remains paramount for informed decision-making and upholding quality standards.

If you want to know more about this testing instrument then you can give us a call at +91 9313 140 140 & info@testronixinstruments.com.