Reviewed by Anurag Mishra (Sr. Technical Consultant)

Ever send out perfectly packaged products, to later get angry emails from customers about leaking bottles or damaged goods? You did everything right-or so you thought. The packaging looked great, but sometime in the transport process, it fell apart. If you ship products that have to be perfectly sealed, such as various beverages, liquid items, semi liquid food items, you would probably have had that nightmare happen to you. And it's no secret that it is very much infuriating, as well as expensive. But what if I said one simple test could have saved you from that headache?

Enter the Vacuum Leak Test. Whether it is as a packaging manufacturer, or in the line of high-value products, this can be your ticket to the reliability of your packaging.

More simply put, one of the leak testing methods used to check for tightness, or integrity in sealed packaging involves the use of a vacuum. This test simulates conditions, your packaging will endure through transportation, or storage, particularly if changes in atmospheric pressure occur. It serves to uncover minute leaks in your packaging that you may have missed, and ensures that your product will not show up at its destination damaged, or otherwise compromised.

Just imagine, sending products that can be as sensitive as a cosmetic serum, or even vacuum-sealed food items. Everything can go bad, if your packaging isn't leak-proof. It will most certainly destroy the product. Worse still, you will have lost trust with your customer.

Just think of it, a package that is damaged, means a refund, or sometimes replacement. Now times this by dozens or hundreds of flawed shipments, and add in the damage to your reputation, and you can quickly see how leak-proof packaging is not an option, but a necessity.

Leak testing of packaging is not as daunting as it sounds. To conduct this test, you neither need a science laboratory, nor are you required to hold a specialized degree in engineering. You can get this right pretty easily. As a matter of fact, the process is very simple.

Here it goes:

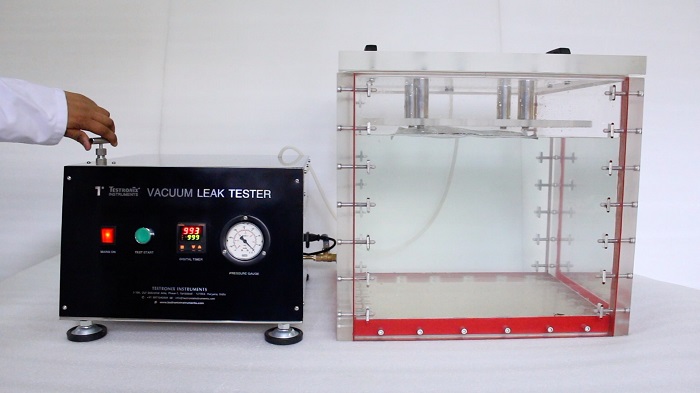

Step 1: Place the Package in the Vacuum Chamber

Suppose you have a whole batch of juice bottles sealed up, and ready for the highway, you immediately take one of those sealed bottles and put it in a vacuum chamber.

Step 2: Pull a Vacuum

Immediately following the enclosure of the package, the machine pulls a vacuum that simulates any pressure change that the package would experience during transportation, including shipment by air. The tugging force of the vacuum reaches down on the package to create low pressure within the chamber.

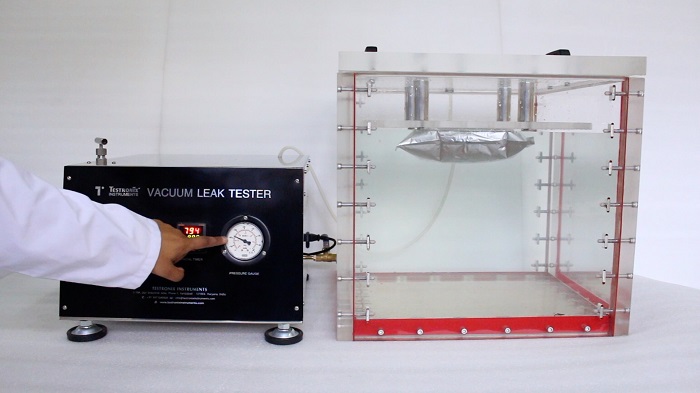

Step 3: Leak Detection

If there is any leak, the difference in pressure forces air to escape from the package. This will be detected by the machine, and the test will show either your packaging is airtight or not.

Step 4: Results and Analysis

When it is done, you get a result as to whether your packaging passes or fails. Of course, if it fails, you will know that somewhere in the cosmetics packaging design or materials, there is some kind of weak point that needs to be acknowledged and improved.

Example: Cosmetics Manufacturer

For example, a cosmetics company could send out thousands of skincare bottles across the country. One day, it receives a call that one of its shipments has been returned because half of the bottles inside leaked during transport. They go through their quality control but the problem isn't detected until they perform tests for vacuum leaks. And voila. The test detects that the bottles weren't sealed properly, which one wouldn't have been able to find out with naked eyes.

Because the vacuum test is in place, they are able to fix the issues prior to shipment and avoid the loss of thousands of units, thus keeping their customers happy.

KNOWLEDGE CORNER

Yes! Leak testing using a vacuum can be very sensitive, detecting even the minutest leaks that may not be visible to the human eye. This is mainly very helpful for products where even a tiny breach in the seal results in spoilage or contamination.

Yes, you need a vacuum leak tester designed for this purpose. Such machines come in a number of sizes, depending on the nature of packaging to be tested.

Not at all! A vacuum leak test normally takes just a few minutes. That's an awfully small investment of time against such great assurance.

Helping you to Stay Ahead of the Curve!

Want to keep your processes flawless? Discover the best solutions for your packaging needs by exploring our latest testing equipment.

Phone: +91 9313 140 140

Email: info@testronixinstruments.com