Reviewed by Anurag Mishra (Sr. Technical Consultant)

There are perishable & non-perishable items that are seal-packed to ensure their safety against spoiling, rusting, or other degrading factors present in the environment. These packaging are crucially executed over items to safeguard them from various degrading factors.

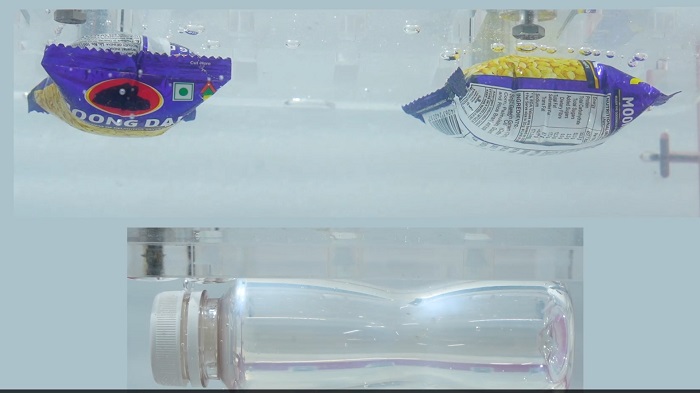

The manufacturers of such packaging materials manufacture both porous & non-porous packaging pouches as per the requirement of the item packed inside such pouches.

However, it becomes crucial for manufacturers to assess the quality of the manufactured product before they are out for sale to ensure maximum customer satisfaction. The quality assessment is quite a challenging task for such manufacturers as achieving accurate conclusions is not fairly easy.

To curb this budding issue of manufacturers, Testronix has come up with an exciting solution called the vacuum leak tester panorama - digital.

The instrument is designed to assess the seal integrity of both porous & non-porous packaging pouches. Using this vacuum leak tester for packaging is extremely important to avoid contamination by measuring the seal integrity of the specimen by assessing it at different vacuum pressures.

The instrument is majorly designed to aid the manufacturers of PET bottles, the flexible & rigid packaging industry.

To understand how the instrument has revolutionized the assessment of seal integrity of packaging, it is important to understand the functioning of the vacuum leak tester panorama – digital.

The vacuum leak tester for packaging is designed with an operator-centric approach for simplistic functioning and achieving accurate results over & over again.

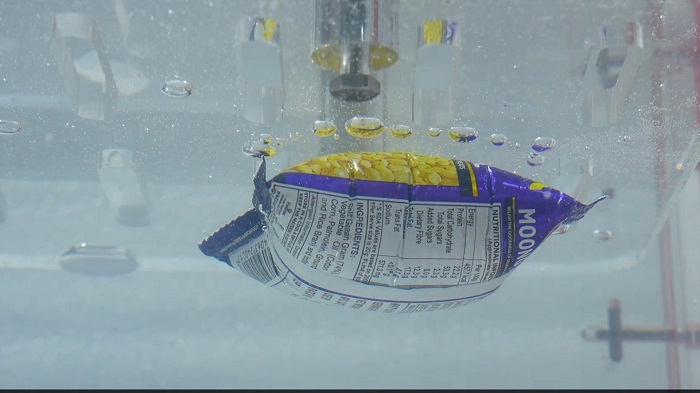

The specimen that is going to be tested is placed within the desiccator bowl and the desiccator panel is closed to ensure no air pressure from the external environment that may hamper the test results.

Once the operator makes sure that the desiccator lid is closed tightly and the atmospheric contact from the outside cannot impact the conditions inside the desiccator, a flow of air pressure is initiated inside the desiccator.

The air pressure is exerted through a pressure valve by the operator inside the desiccator which forces a formation of vacuum within the packaging. The vacuum exerts pressure on the wall and if the specimen withstands a certain level of pressure the specimen is fit for the end user. However, in the case of contrary results wherein the specimen is unable to withstand the vacuum forced on its walls due to the formation of air pressure outside the uncertainties are determined by the manufacturer of the product.

The air pressure that is exerted within the desiccator of the vacuum leak tester for packets is monitored directly through a pressure gauge which enables the operator to record accurate values and analyze as per the requirements of the consumer.

The vacuum leak tester manufacturers have designed the equipment with an approach of providing maximum features built into the instrument. This derives maximum accuracy and ease of handling for the operator.

The instrument is equipped with high-end as well as technologically advanced features that enable the instrument to assess results precisely and aid the manufacturer performs tests with absolute facile.

The vacuum leak tester panorama - digital is offered with a pre-set timer setting functioning along with an inlet pressure setting mechanism that enables the operator to perform repeatable testing.

The vacuum leak tester for packets comes with a high-end dual-layer PMMA polished chamber which is transparent to make sure that there is no leakage of vacuum during the test and also the transparent factor enables the operator to observe the effects of vacuum over the sample at all times during the test.

The pressure valve of the instrument is ergonomically designed for easy handling along with a monitoring dial gauge to assess the value of pressure being exerted into the desiccator or the vacuum chamber.

To ensure uniform and consistent pressure at all times inside the vacuum chamber, the vacuum leak tester manufacturers have designed an inbuilt pressure vacuum. The top-notch equipment ensures uniformity & consistency of air pressure within the chamber at all times during the testing.

The ability of the instrument to determine the quality of both porous & non-porous packaging materials aids the manufacturer a lot when it comes to feasibility.

All these features combined make the lab testing instrument a high-end device for assessing the vacuum leakage of packaging materials in order to safeguard them against contamination.

To know more about the high-end lab testing instrument from the Testronix, contact the vacuum leak tester supplier itself by simply visiting our website. Please feel free to contact us for questions & queries regarding technicalities or price range of lab testing instruments via phone call at +91 9313140140 or e-mail us at info@testronixinstruments.com. As a vacuum leak tester supplier & other lab testing instrument manufacturer, we will make sure to assist you with the finest services possible.