Reviewed by Anurag Mishra (Sr. Technical Consultant)

There are numerous industries including rubber manufacturing, agriculture, metal treatment, and medical research highly concerned about the burning properties of various materials. There are certain aspects other than measuring the burning speed and flammability of a material, one such aspect is the ash content percentage determination on getting burnt.

For example, in the field of agriculture, numerous pesticides and artificial manures are used which are burnt after the agricultural process is completed so that they do not hamper the soil in the long term. Therefore, it becomes important to measure the ash content that is produced by burning them so that the soil does not contain their ash leftovers and hamper future agricultural activities.

To overcome the issue of calculating the ash content without any hassle & jeopardies, the leading lab testing manufacturer in the country – Testronix has come up with an extremely vital lab testing instrument called the muffle furnace. The instrument is designed with high-class engineering to elevate the testing standards to determine the ash content generated on the burning of various products.

The instrument has an extremely ergonomic design structure that attracts manufacturers from all across industries to perform the test. The ergonomic structure of the instruments not only enhances the ease of testing but also provides a sense of safety & security.

The muffle furnace manufacturer has made sure that the instrument is equipped with top-notch safety measures to conduct the test and achieve maximum levels of accuracy.

To commence the test, the operator has to open the door of the inner chamber of the instrument and place the specimen in the muffle furnace. It is necessary for the operator to make sure that the specimen is not bigger than the crucifix so that the burnt ash is collected inside the crucifix itself.

The operator can now place the crucifix inside the testing chamber of the muffle furnace and close the door firmly by ensuring it with the lock mechanism integrated into the door.

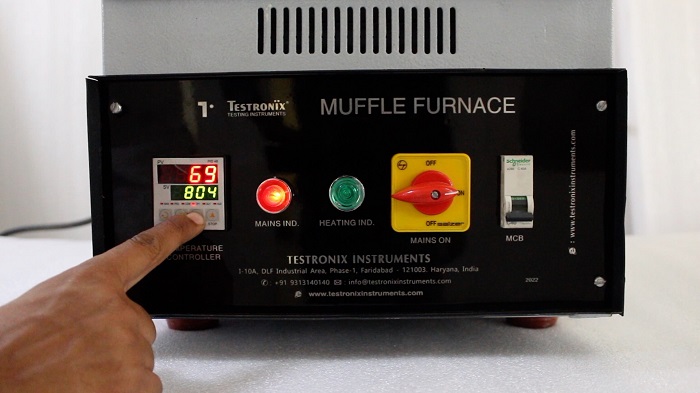

Once the door is locked firmly, the operator can adjust the setting of the preset timer and the temperature of the heaters with the help of the feather touch controls & the rotary switch associated with the control panel.

After the operator adjusts the settings from the control panel, the inner chamber that is integrated with U-type heaters elevates the temperature inside the inner chamber. The U-type assembly of these heaters integrated into the inner side of the walls ensures uniform heating all across the specimen.

The operator can easily adjust the preset timer which determines the running time of the instrument. Once the time adjusted on the preset timer is achieved, the instrument cuts off the heating supply and turns the instrument, allowing the operator to unlock the door and open the door to bring out the crucifix containing the ash content.

It is highly necessary for the operator to take the crucifix out with the help of a tong provided along with the instrument as the crucifix gets super-hot to be touched with naked hands. Once the ash content is out, the operator can easily assess & calculate the percentage of the same.

This is how the muffle furnace conducts the test with such facile & eases. The credit for such ease of testing goes to the muffle furnace manufacturer – Testronix, who imbibed top-notch specifications within the construction of the instrument.

The specifications of the instrument are responsible for the trust of manufacturers within the working module and the result deliverance of the instrument.

Do not wait any further and get yourself the highly valued muffle furnace for the assessment of the ash content generated on burning variable material types. To seek more knowledge & info about the instrument, you can find it on our website. Get free installation at your lab by reaching out to us via phone call at +91 9313140140 or via e-mail at info@testronixinstruments.com.