Reviewed by Anurag Mishra (Sr. Technical Consultant)

There are numerous challenges that are faced by corrugated boxes during storage & transit measures which make the jobs of shipment operators tougher and also urge manufacturers of these packaging products to elevate the quality of the product being packed inside.

Manufacturers of the packaging industry adhere to the guidelines of designated standards to achieve a certain level of quality and make sure that the corrugated boxes are durable enough to withstand impacts from free falls during storage measures. These free falls can occur due to rough handling or unskilled labour stacking corrugated boxes which can lead to fatal injuries as well as hefty losses to the manufacturer in case of damage to the product.

There are several other factors that hamper the quality of a corrugated box but the maximum damage experienced by the product inside the specimen is during free-falls. It is the foremost duty of manufacturers to make sure that the corrugated boxes designed are absolutely top-notch and can easily withstand such impacts without any hassle.

The finest lab testing instrument manufacturer - Testronix has designed a top-notch lab testing instrument called the Drop Tester Motorized that imitates real-life drops experienced by corrugated boxes during stacking, storage & transportation of products from one place to another.

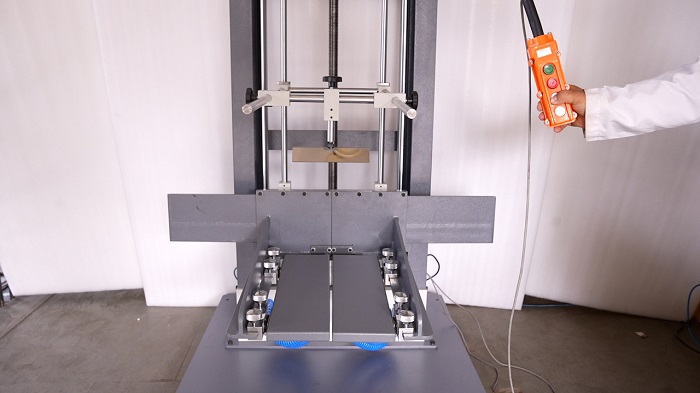

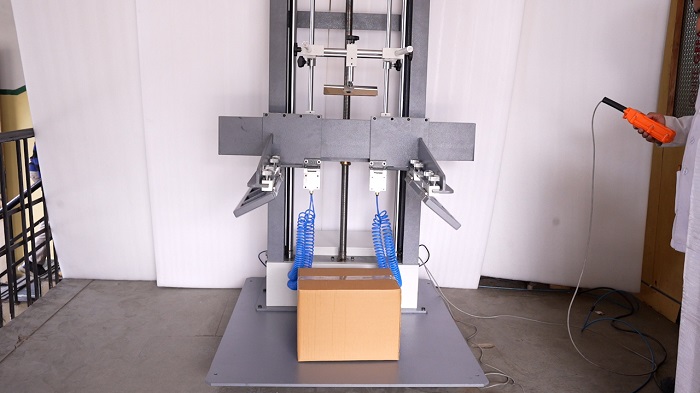

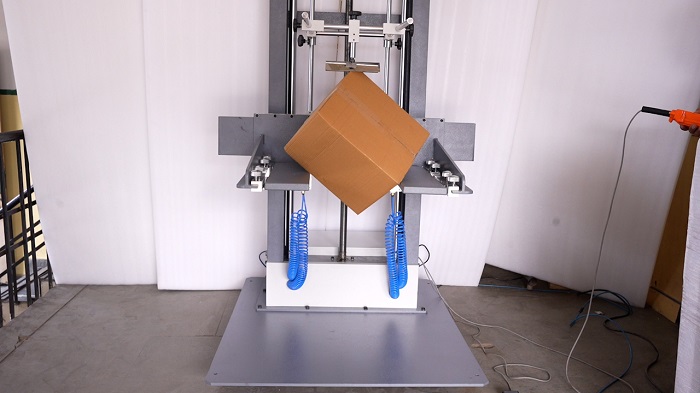

The drop tester is designed with utmost precision to assess & evaluate the change in physical properties that occur due to drops from certain heights. The working process of the drop strength tester is highly ergonomic and easy to use to assist the operator of the instrument to get familiar with the machinery and equipment for a quick testing process.

To perform drop testing, an operator must take care of all the necessary steps and ensure that the steps are taken in the right way to achieve highly accurate as well as precision-based test results.

This is how the drop testing machine performs the test and determines the impact resistance of corrugated boxes when they experience free falls during transit or storage measures.

Drop Testing Machine is offered with such amazing and top-quality working modules that it has captured the attention of each & every manufacturer from the packaging industry.

The lab testing machine is equipped with specifications that comply with all the necessary standard guidelines to enhance the quality of testing and ensure a much more seamless testing experience.

With all these specifications intact, the lab testing instrument precisely caters to operators & manufacturers across the globe with standard compliances and helps them achieve highly accurate test results over & over again. The ergonomic body structure along with robust construction also enhances the testing experience of the operator and ensures a sense of security among manufacturers prevailing from various industries.

The lab testing instrument is available with all the necessary specifications on request as per the demand of the specimen on our website. Do not wait any further and reach out to us via phone at +91 9313140140.

You can also avail the finest quality of after-sales support by joining hands with the leading lab testing instrument manufacturer – Testronix. To give us feedback you can directly contact us via e-mail by writing about the after-sales service experience as well as your experience with the instrument so far at info@testronixinstruments.com.

The company aims to provide the best-ever lab testing instruments to its customers by incorporating all the top-notch features into it.