Reviewed by Anurag Mishra (Sr. Technical Consultant)

Drop testing is a crucial aspect of product development and quality control. It involves subjecting items to controlled impact forces to simulate real-world scenarios and assess their durability. However, the effectiveness of drop testing heavily relies on the proper maintenance of drop testers. By performing proper maintenance tasks for drop strength tester, manufacturers can easily use this lab testing instrument for years. Testronix drop testing machine provides easy testing features with angular drop testing facility.

In this blog post, we'll delve into why maintaining a drop tester is so important and provide you with practical tips on how to keep it in top-notch condition. But first, we will discuss about the drop strength testing.

Drop strength testing is a crucial aspect in the realm of packaging, ensuring the durability and protection of products during transportation. This process involves subjecting packages to various simulated drops and evaluating the package’s ability to withstand impact forces.

With the help of a manual drop tester, manufacturers can easily test the reliability of boxes when dropped from different heights and at different angles. This high-quality drop strength tester has been designed as per industrial standards including ASTM D5276. It will provide an accurate drop facility and ensure reliability in test results.

You can read more on the importance of drop testing in e-commerce packaging. Now, let us discuss some easy-to-follow steps for maintaining drop strength tester.

Maintaining a drop tester efficiently is crucial for ensuring accurate and reliable testing of products and materials, especially in industries where impact resistance and durability are paramount. Thus, we have come up with some useful tips to maintain the drop strength tester more efficiently:

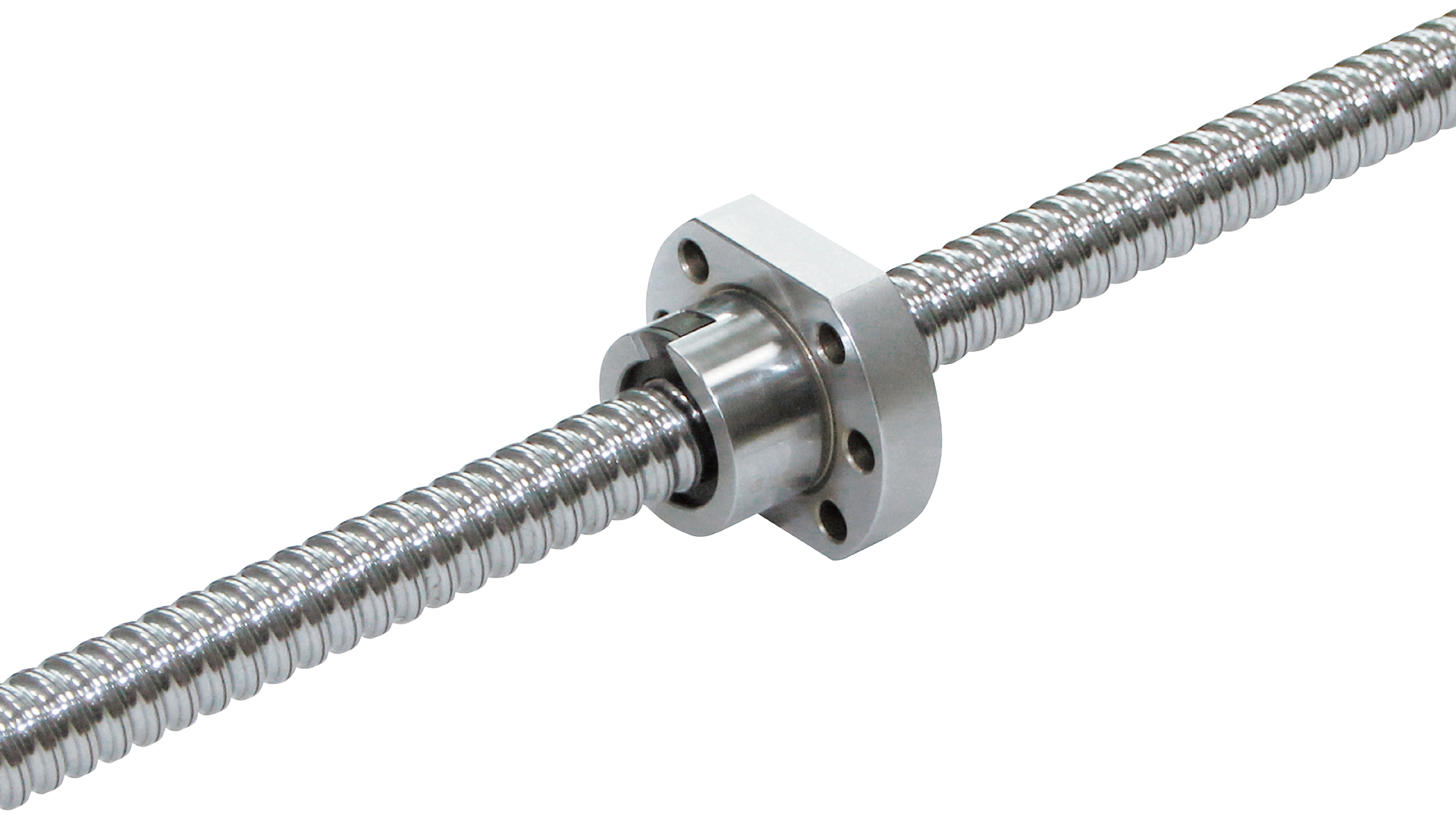

The lead screw is a crucial part of the drop tester that controls the vertical motion during the drop. Proper greasing of the lead screw is essential to reduce friction and ensure smooth and precise movement. Regularly apply a suitable lubricant to the lead screw, as recommended by the manufacturer, to prevent wear and tear. Over time, dirt and debris can accumulate, so clean the lead screw before reapplying grease.

The guide rod plays a vital role in maintaining the alignment and stability of the drop tester's components. Apply oil to the guide rod as per the manufacturer's guidelines to reduce friction and maintain its functionality. Keep an eye out for signs of wear, corrosion, or misalignment on the guide rod, and address any issues promptly to ensure accurate testing.

Another important maintenance tip that you must remember is to regularly inspect all components of the drop testing machine & ensure accurate and reliable test results.

Ensure that all safety features and emergency stop mechanisms are in working order. Safety should be a top priority when using a drop tester. Regularly test and verify that these features function correctly to protect both the equipment and the operators.

It is important to maintain the drop testing platform efficiently by regularly inspecting it for dust and debris and ensuring accurate and reliable test results. A well-maintained drop platform ensures the accurate positioning of the test specimens.

By following these guidelines and addressing the specific maintenance needs of your drop tester, you can ensure its accuracy and reliability, which is crucial for conducting dependable product testing and quality control assessments.

Proper maintenance plays a crucial role in ensuring accurate and reliable results when it comes to drop testing. Neglecting the maintenance of a drop tester can lead to various issues that not only compromise the integrity of the testing process but also pose potential risks to personnel and equipment.

You can also read more on the top 3 mistakes that you must avoid during the drop testing procedure. Regularly inspecting, cleaning, calibrating, and lubricating your drop tester will help identify any issues or malfunctions before they escalate into more significant problems. This proactive approach allows you to address concerns promptly, ensuring that your tests yield precise and consistent results.

If you have bought a drop tester and need help with its maintenance then you can give us a call at +91 9313 140 140 or email us at info@testronixinstruments.com.