Reviewed by Anurag Mishra (Sr. Technical Consultant)

In today’s global market, ensuring the quality, safety, and performance of products and materials is crucial. Standards play a key role in this process. Among the most widely recognized and used standards are those developed by ASTM International, previously known as the American Society for Testing and Materials.

These standards guide industries across various sectors, from construction and manufacturing to healthcare and transportation. This article is a complete guide on what the ASTM standard is, its full form, how to use it, and various applications in manufacturing industries.

ASTM International Standards are technical guidelines developed by ASTM International to ensure materials and products meet specific requirements. These standards cover testing methods, specifications, classifications, and practices that help industries maintain consistency, quality, and safety.

Currently, there are approximately 13,000 ASTM Standards in use across the globe. They help to make products better, keep people safer and healthier, make it easier to sell stuff in different markets, and give customers more faith in what they are buying.

ASTM main headquarters are in West Conshohocken, Pennsylvania. They also have offices in Belgium, Canada, China, Peru, Singapore, and Washington, D.C.

ASTM full form is American Society for Testing and Materials, which develops and publishes international standards for a wide range of materials, products, and services. These standards provide a basic set of technical requirements that can be used for design, assessment, testing, and quality control in different fields.

ASTM International Standards are fundamental in ensuring various benefits, including quality and Consistency, Standardized Testing Procedures, Facilitating Global Trade, Cost-effectiveness, Benchmarking, and Certification.

ASTM Standards provide clear benchmarks for evaluating the physical, mechanical, and chemical properties of materials and finished goods. By adhering to these benchmarks, manufacturers can guarantee product consistency and ensure that the output meets both customer and regulatory expectations.

One of the most significant contributions of ASTM is its library of standardized test methods. These methods enable precise and reproducible testing across laboratories and industries, eliminating ambiguity and ensuring uniformity in results.

By offering universally accepted technical references, ASTM International Standards help eliminate trade barriers. Buyers, suppliers, and certification bodies across borders use ASTM Standards to verify that products meet required specifications, thus streamlining international procurement and collaboration.

One of the most compelling benefits of adopting ASTM Standards across industries is cost-effectiveness. These standards provide a unified framework for designing, testing, and producing materials that directly contribute to minimizing operational costs and improving process efficiency.

Third-party certification agencies and auditors rely heavily on ASTM Standards for benchmarking and certifying products, materials, systems, and personnel. This builds consumer trust and adds credibility to product claims.

In the construction industry, ASTM stands for the American Society for Testing and Materials, now known as ASTM International. Such standards play a vital role in maintaining quality, safety, and performance across construction projects. Reliable guidelines are provided for the testing, design, and application of building materials and techniques.

Uses of ASTM in Construction:

Ensures the quality and consistency of construction materials such as cement, concrete, steel, and asphalt.

Provides testing standards for materials to verify strength, durability, and performance before use.

Assists in regulatory compliance by aligning with building codes and safety standards.

Supports product certification and approval processes in government and private projects.

Helps minimize construction failures and defects through standardized procedures.

Facilitates global trade and procurement by ensuring that materials meet internationally accepted benchmarks.

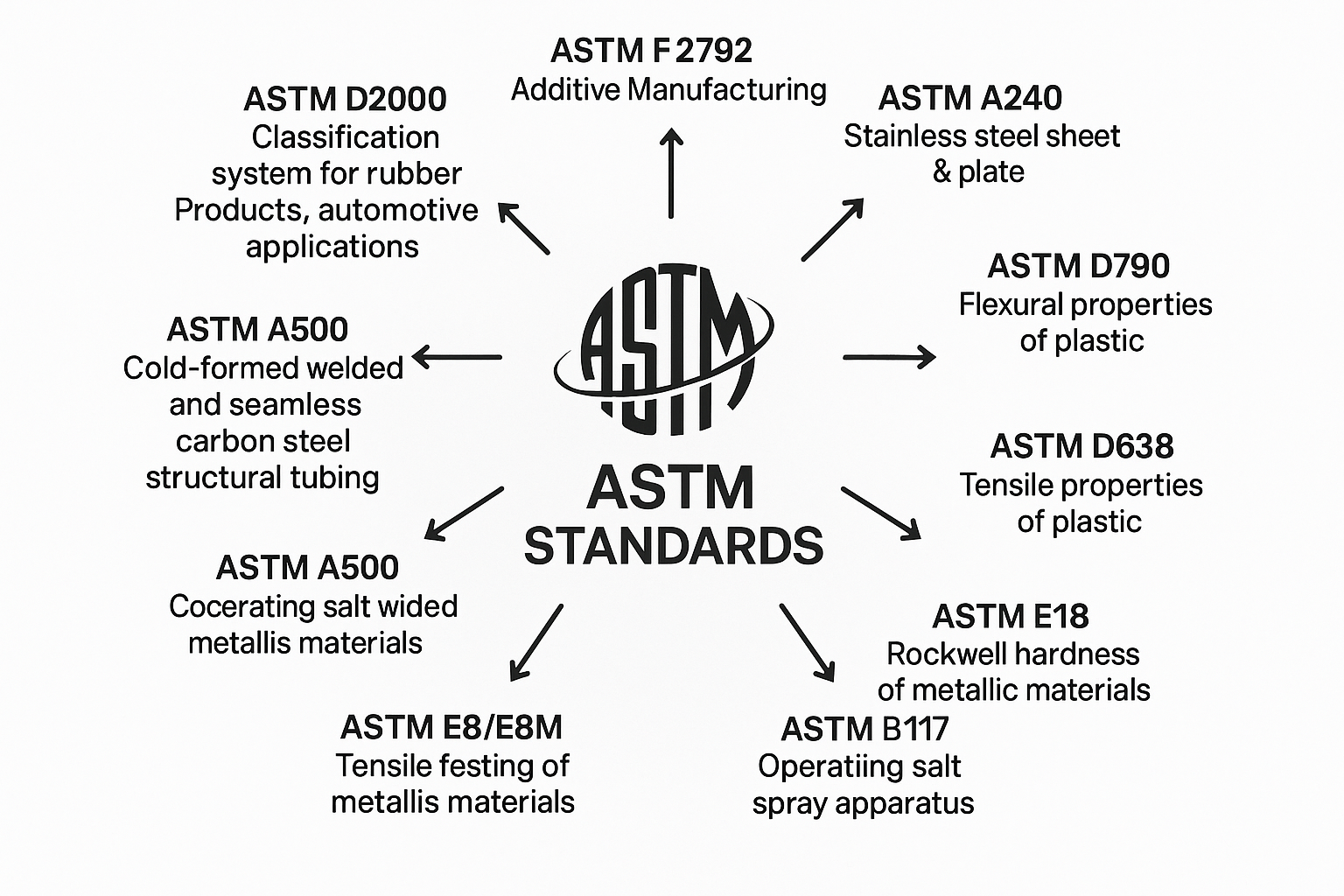

ASTM International has developed more than 12,000 standards that are commonly used in industry to facilitate product quality, safety, and performance. The standards include materials, methods of testing, specifications of products, and many others. Here are the top 10 most-used ASTM standards in manufacturing industries:

ASTM F2792 – Additive Manufacturing

ASTM A240 – Stainless steel sheet & plate

ASTM D790 – Flexural properties of plastic

ASTM D638 – Tensile Properties of Plastic

ASTM E18 – Rockwell hardness of metallic materials

ASTM E112 – for determining average grain size

ASTM B117 – Operating Salt Spray Apparatus

ASTM E8/E8M – Tensile testing of metallic materials

ASTM A500 – Cold-Formed Welded and Seamless Carbon Steel Structural Tubing

ASTM D2000 – Classification System for Rubber Products, Automotive applications

ASTM Standards have six different types of Standards: Test Methods, Practice Method Standards, Specification Standards, Classification Standards, Guide Standards, and Terminology Standards. Here is an explanation of these different types of Standards.

These are standardized methods designed to produce consistent and reliable test outcomes, typically used to identify, measure, or assess specific properties or characteristics.

Practice Method Standards provide procedural guidelines for carrying out specific operations that do not yield measurable test results. They may include tasks such as cleaning, sampling, training, inspection, or material preparation.

Specification Standards outline the mandatory criteria that a material, product, system, or service must fulfil. They include defined test methods to verify compliance with physical, chemical, mechanical, safety, quality, and performance requirements.

Classification Standards provide a systematic framework for dividing materials or products into groups that exhibit similar traits in terms of behaviour, composition, or practical use.

Guide Standards present general information and a range of possible approaches without endorsing any method. They are intended to inform stakeholders about current practices within a specific subject area.

These standards provide clear definitions of terms along with explanations of symbols, abbreviations, and acronyms used within a particular field.

ISO and ASTM International standards both serve to ensure quality, safety, and consistency, but they differ in scope and approach. ISO develops globally recognized standards through international consensus, often focusing on management systems and broad frameworks. ASTM, on the other hand, primarily provides highly detailed technical standards, especially for testing methods and material specifications.

While ISO is international in origin, ASTM originated in the U.S. but is now used worldwide, particularly in industries requiring precise testing and product validation.

| Feature | ASTM | ISO |

| Full form | American Society for Testing and Materials | International Organization for Standardization |

| Origin | USA | Global (based in Geneva, Switzerland) |

| Focus | Detailed technical methods and specs | Global consensus and harmonization |

| Usage | Widely used in North America | Widely used in Europe, Asian, and other regions |

| Document Structure | More prescriptive | More performance-based |

ASTM rating stands for American Society for Testing and Materials. It signifies that a product or material complies with a specific ASTM standard. For example, a helmet with an “ASTM F1492” rating meets the safety requirements for skateboarding helmets as defined by ASTM.

Yes, ASTM international standards are widely used in India across sectors such as construction, pharmaceuticals, automotive, and manufacturing. Many Indian companies and testing labs follow ASTM procedures, especially when exporting products to countries like the USA and Canada.

ASTM standard is an important document, especially for the manufacturing industry, because it ensures product quality, safety, and reliability. It is done through standardized testing methods accepted globally across industries.

Applying ASTM standards provides several benefits, including consistent quality, enhanced product safety, support for regulatory compliance, improved market acceptance, reduced costs, and the facilitation of global trade through universally recognized testing and performance benchmarks.

What is Laminar Air Flow?

What is Moisture Meter?

What is PH Meter?

What is Ash Value?

What is Compressive Strength?

What is ESCR?

What is a Water Bath?

What is Melt Flow Rate?