Reviewed by Anurag Mishra (Sr. Technical Consultant)

Manufacturers and customers have raised their desire for "zero rejections" and enhanced quality, which has resulted in an increase in the specification of salt spray tests. Thus, the need for this corrosion stimulating test has also arisen that helps to predict the corrosion resistance of finished parts in service. To easily conduct this quality test for coated parts made up of stainless steel, brass, or other metals, you can make the use of Testronix salt spray chamber.

A salt spray chamber is considered to be a type of environmental test chamber that will be designed to expose a coated object to a highly corrosive environment. This testing instrument is widely used in aerospace, automotive industries, and other related industries where there is a need to test the surface coatings of the materials. Conducting a salt spray test requires preparing a salt spray solution. Here in this blog, we are going to discuss salt spray tests of surface coatings and steps to prepare the salt spray solution to conduct this test.

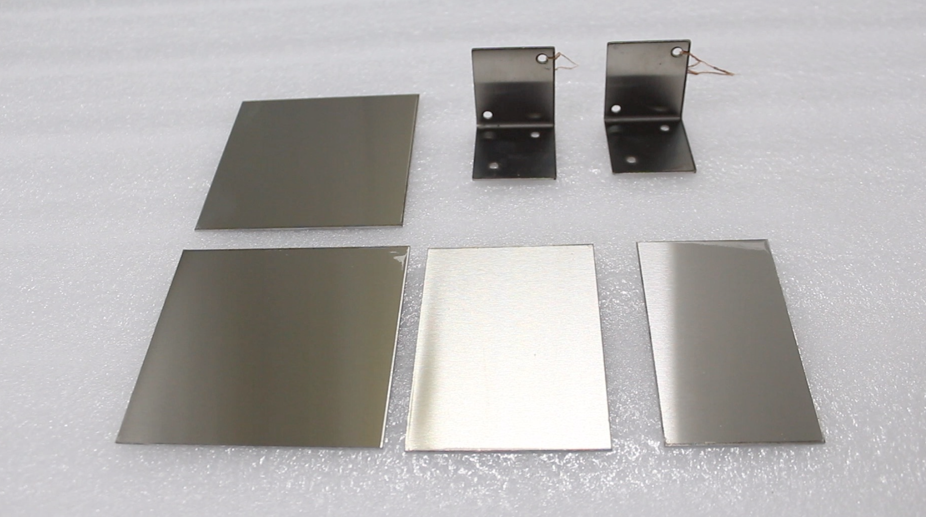

A salt spray test is a corrosion test that employs high-saline settings to determine the corrosion resistance of items, paints, and coatings over long periods of time. A salt spray test, also known as a salt fog test, & is performed in a closed chamber that may be altered to simulate a range of corrosive conditions. During testing, samples are exposed to a precise salt concentration for a set duration of time, as established by the specification, product type, or industry norms.

A standardized solution of 5 percent NaCl (sodium chloride) is used to generate a highly corrosive environment in a conventional salt spray test. We may typically modify ambient factors like temperature and humidity to imitate certain climates or working circumstances for projects with special requirements.

Samples are often tested at regular intervals to track corrosion levels, such as the formation of white and red rust or coating loss. From start to end, our salt fog test chamber can produce thorough test results that contain photographs and descriptions of each stage of testing.

The ASTM B117 salt spray test is used to examine the effects of corrosion on a testing specimen, this approach includes producing a controlled accelerated corrosive environment in a salt spray cabinet or chamber. We at Testronix is considered to be the best manufacturers of salt spray chamber in India that produces the right testing specimen that will help you analyze the effects of corrosion on surface coatings. Below we have listed the features and technical specifications of this lab testing equipment.

The Testronix salt spray chamber has been embedded with several amazing features that will help you to conduct the test with ease. Below we have listed the features of this testing machine.

1. Air saturator- to saturate the air inside the chamber for compliance with ASTM B117

2. Fog collection unit

3. pH meter- to check the pH of salt solution

4. Pneumatic opening of canopy for ease in operation

This lab testing instrument is very beneficial for your metal firm. You can easily conduct the test using by using our lab testing instrument that is designed as per industry standards. Here we have listed the steps to prepare a salt solution to initiate this test.

Whenever you conduct a salt spray test with the help of this coating measurement test chamber then you need to prepare the salt solution first. Thus to easily prepare the solution with the help of this lab testing equipment you can follow the below-mentioned steps.

Connect external solution tank of minimum 8 Feet height (Under Customer’s Scope). For this, connect the M8 PU Pipe with the Salt Solution Inlet Port and fill the salt solution. In this way, you can easily prepare the salt solution with the help of this lab testing equipment. If you want to know how this corrosion testing chamber is beneficial for the manufacturers in long run then give us a call at +91 9313 140 140 or email us at info@testronixinstruments.com. Our team of technical experts will easily assist you with all your queries.