Reviewed by Anurag Mishra (Sr. Technical Consultant)

Measuring the rub resistance of packaging films is of utmost importance in making the product more durable during handling. The damage that occurs during the shipment, storage, and handling of products will lead to poor quality products and can even affect your reputation. Thus, testing the ink abrasion rub resistance properties of these products will help the product owners to deliver quality products to the customers. Thus, this can be done with the help of a Testronix ink abrasion rub tester. This is one of the amazing lab testing equipment that has been designed to test the quality of labels and packaging materials.

By testing your product with the help of this lab testing instrument, you will be able to check the smudging properties of these materials that may occur during transportation and shipping. This lab testing equipment will adhere to all industrial standards and can prove to be helpful in the packaging sector. In this blog, we will discuss how you can easily prepare the sample for testing the ink abrasion properties of your printed materials. But before that, we will focus on how this machine proves to be helpful in the packaging sector.

The ability of printed material to survive marking, scuffing, or smear throughout handling, packing, shipping, distribution, and usage is referred to as rub resistance. To guarantee that standardized items are given to clients, you must test the rub resistance of printed labels. This will ensure that the correct materials are delivered to your customers.

By imitating the real application environment and assessing the abrasion resistance of the printed material's surface coating layer, this lab testing equipment is used to evaluate the label's life. It stimulates the product's real-world working environment and determines the label printing quality and procedure based on the product's application and operating environment.

Testronix ink abrasion tester has been designed with advanced technology that makes it easy for you to evaluate the print quality of two surfaces when rubbed against each other. If the print quality rub resistance test will be done manually then rubbing cannot be quantified and will be kept constant.

Moreover, it is difficult to keep the plane of contact constant and keep a track of the number of rubs. Hence making this method highly operator dependent. This rub tester overcomes this by rubbing two printed surfaces against each other face-to-face, at different speeds. This ink rub tester serves to be advantageous for your printing labels manufacturing firm. You can read the benefits of ink abrasion tester in the printing industry.

Let’s focus on the features and technical specifications of this lab testing equipment.

Abrasion resistance of surface layers of printed materials (ink layer or photosensitive (PS) coating) can easily be measured using the Ink Abrasion Tester. Poor abrasion resistance, ink layer peeling, decreased printable force, and poor hardness of coating layers of printed materials are all difficulties that it needed to be evaluated.

Below we have listed the features you will get with the Testronix ink abrasion tester.

With these features and technical specifications, it will be easy for you to conduct the ink abrasion test by using this rub resistance tester. Now, let us focus on how you can easily prepare the testing specimen for the ink abrasion test.

The Ink Abrasion Resistance Tester has been intended to assess how rubbing and scuffing resistant printed ink is. This ink rub tester may be used to evaluate the properties of printed materials in a controlled testing environment. Now, let us focus on the steps to prepare the testing specimen for the ink abrasion test.

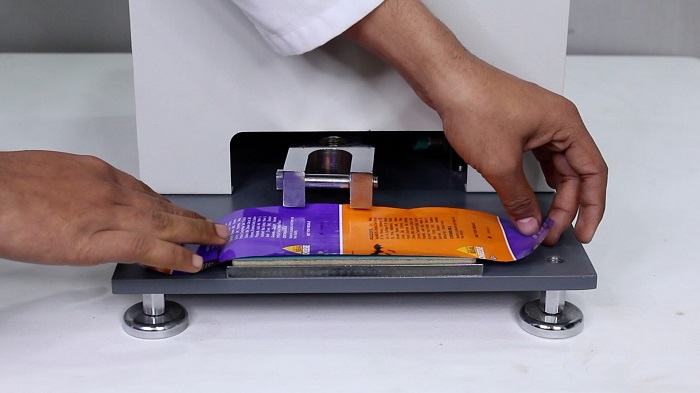

Prepare sample for Upper Clamp:

Sample Preparation for Lower Clamp

In this way, you can easily prepare the sample for conducting this test. We at Testronix are considered to be the leading manufacturers of ink abrasion testers and provide you with high-quality testing equipment. You can easily conduct an online demo for using this testing instrument just by giving us a call at +91 9313140140 or email us at info@testronixinstruments.com. Our team of technical experts will help you by providing the right assistance to all your queries.