Reviewed by Anurag Mishra (Sr. Technical Consultant)

Vacuum leak testing is considered to be a critical aspect of quality control in the packaging industry. These leaks occur due to unwanted gaps that are present in the pouches, flexible packaging products etc. Testing the vacuum leaks is considered to be one of the essential measures of quality control. Thus, with an accurate lab testing instrument known as a vacuum leak tester, manufacturers of the paper and packaging industry can accurately test the vacuum leaks present in the products.

Our digital model of vacuum leak tester offers highly advanced features that make it easy for manufacturers to conduct vacuum leak tests on the materials.

The vacuum leak tester panorama touchscreen has been designed with highly advanced features that make it easy for manufacturers to conduct vacuum leak tests on the materials.

This HMI-based model of vacuum leak tester has been made with highly advanced features that make it easy for manufacturers to conduct vacuum leak tests on the materials. In this blog, we will discuss brief information about the vacuum leak tester panorama and how does this lab testing equipment works. So, let us get started!

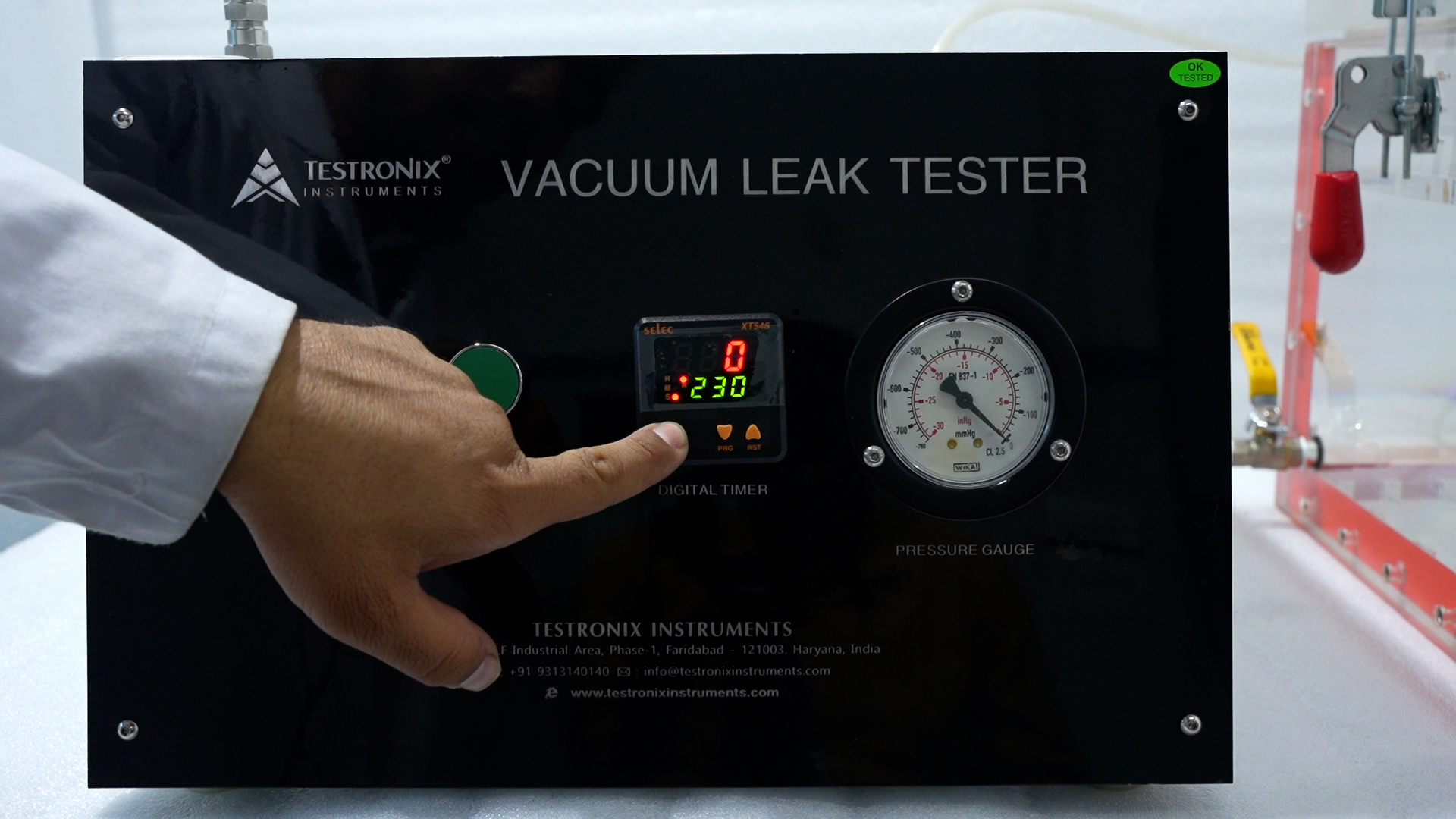

1. Turn the machine ON by plugging the main socket of this testing instrument in the 3-pin 5 amp socket. You will see the HMI screen will turn ON.

2. Set the test duration timing on the digital timer.

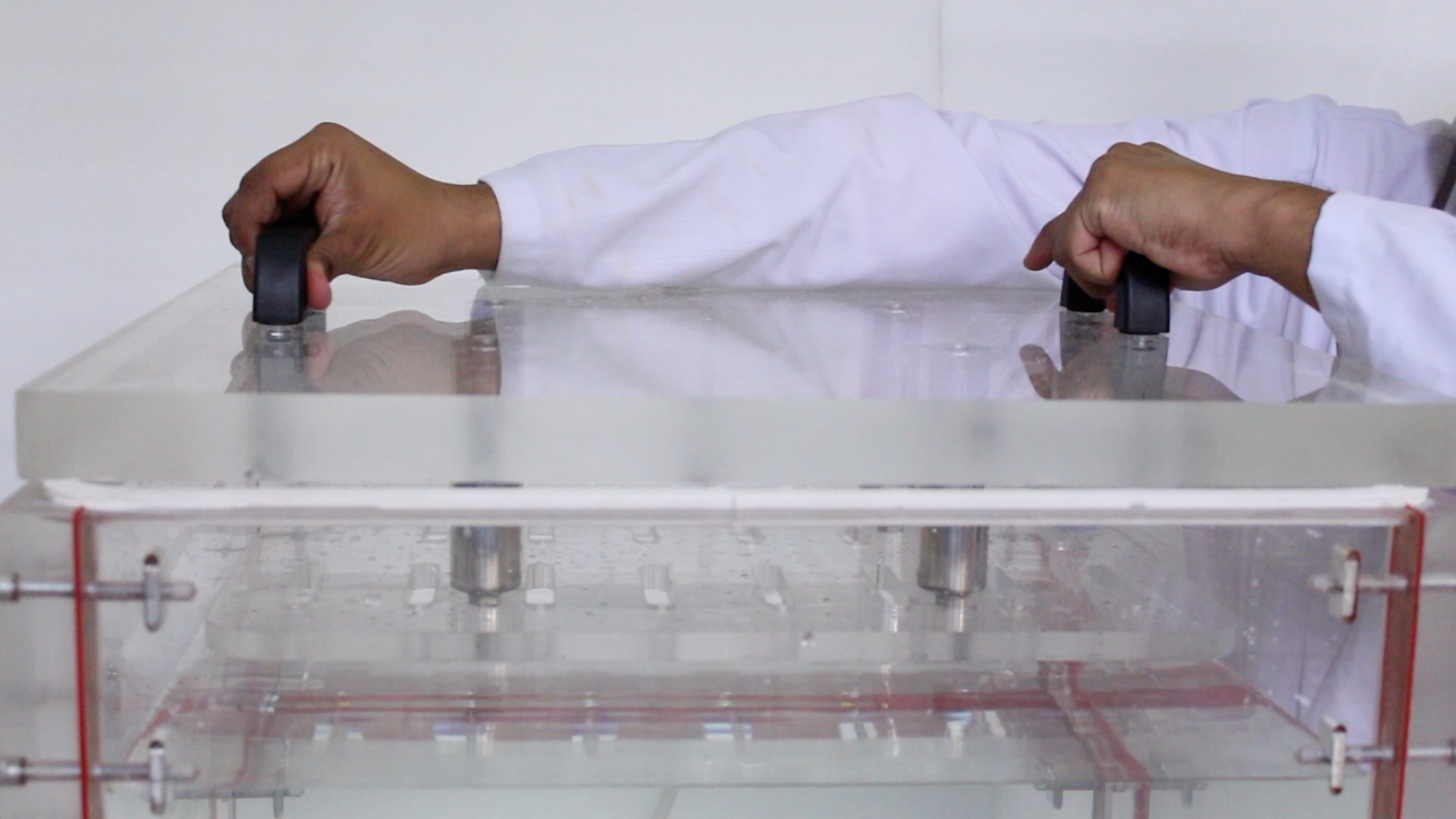

3. After that, place the testing specimen.

4. Put the cover back in the desiccator and ensure that it is properly placed.

5. Once the specimen will be placed, adjust the pressure valve in closed position.

6. When all settings will be done, you can easily commence the test.

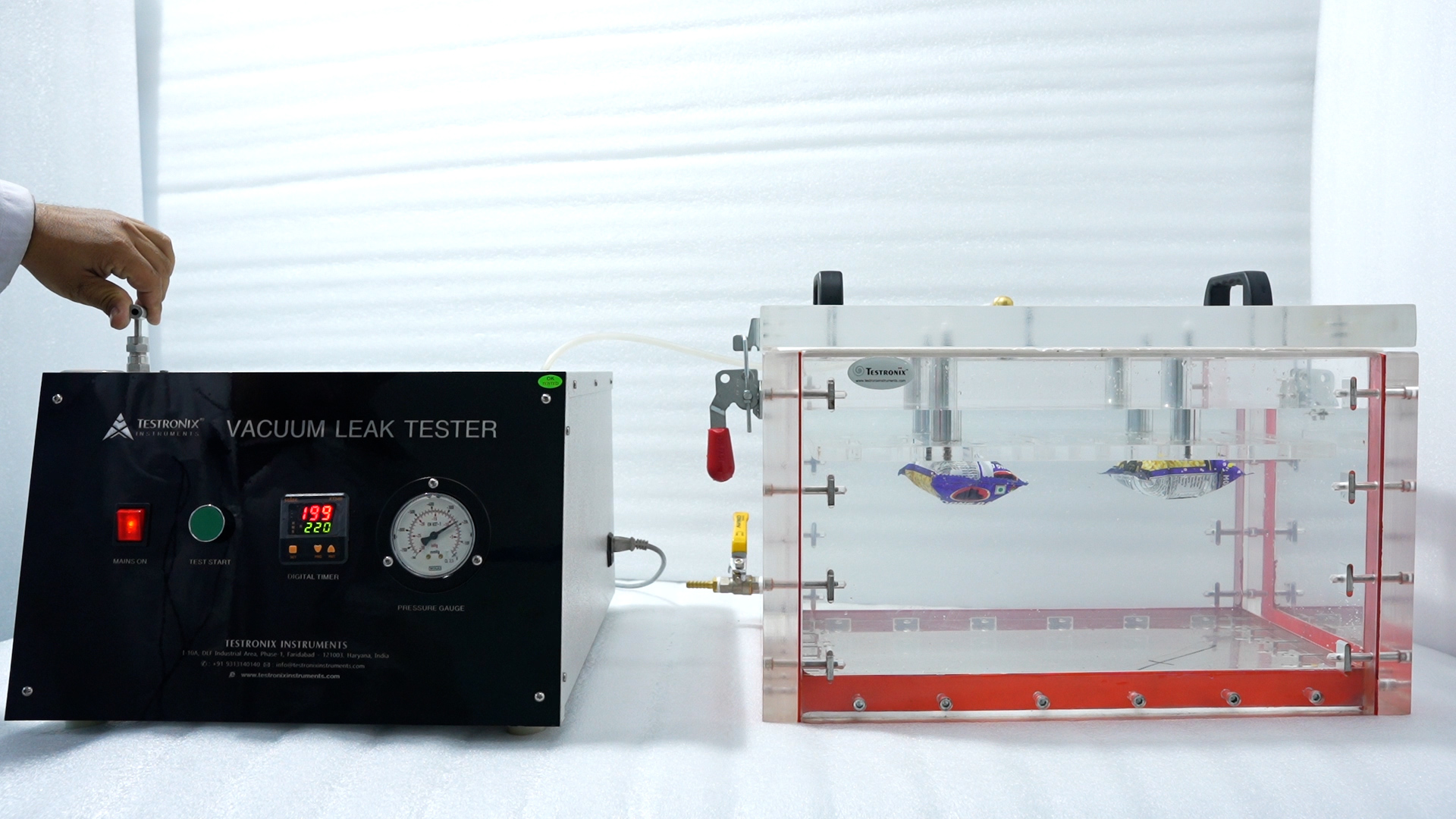

In this way, the vacuum leak tester panorama works. Now, let us discuss the importance of vacuum leak testing in packaging industry.

The use of flexible films is vital in the packaging industry. Vacuum leak testing will help the manufacturers in ensuring the integrity of packages by detecting the vacuum leaks present in the materials that can lead to spoilage of materials and uphold their reputation for delivering high-quality goods while minimizing the losses that occur due to poor quality of products.

Thus, vacuum leak testing will help manufacturers in ensuring the quality of products delivered to the customers. You can also read more on the benefits of vacuum leak testers in the packaging industry.

When it comes to packaging, ensuring product integrity and safety is paramount. That's why vacuum leak testing plays a crucial role in various types of packaging. Let's take a closer look at some common types of packaging that require this important testing method.

These are different packaging materials that will easily be tested using a vacuum leak tester. If you want to give us a call at +91 9313140140 or email us at info@testronixinstruments.com. Our team of technical experts will consult you regarding all your needs and queries.