Reviewed by Anurag Mishra (Sr. Technical Consultant)

The measurement of glossiness in materials serves as a critical parameter in various industries and it plays a pivotal role in quality control of the products. Gloss, defined as the amount of light reflected from a surface, is a fundamental characteristic that profoundly influences the visual perception and overall appeal of materials. Precise gloss measurement not only ensures consistency in appearance but also provides valuable insights into the material's reflective properties, aiding in the formulation of products that meet stringent quality standards. Thus, with Testronix gloss meter triangle testing equipment, manufacturers of different industries can easily test the glossiness of the surface at different angles. The gloss meter allows for accurate and reliable measurements, contributing to the enhancement of product quality and visual aesthetics.

In this blog, we will discuss the importance of gloss measurement in quality testing for different industries. We will also discuss how angle measurement can easily affect the gloss measurement of the materials efficiently.

Gloss measurement is the process of quantifying the amount of light reflected off a surface at a specific angle. This measurement is used to determine the shininess or glossiness of a material. When light hits a surface, it can be reflected, absorbed or scattered. The proportion of light that is reflected directly relates to how glossy or matte a material appears.

In different industries, gloss measurement is an important aspect of quality control and helps manufacturers in ensuring the quality of materials to be delivered to the customers.

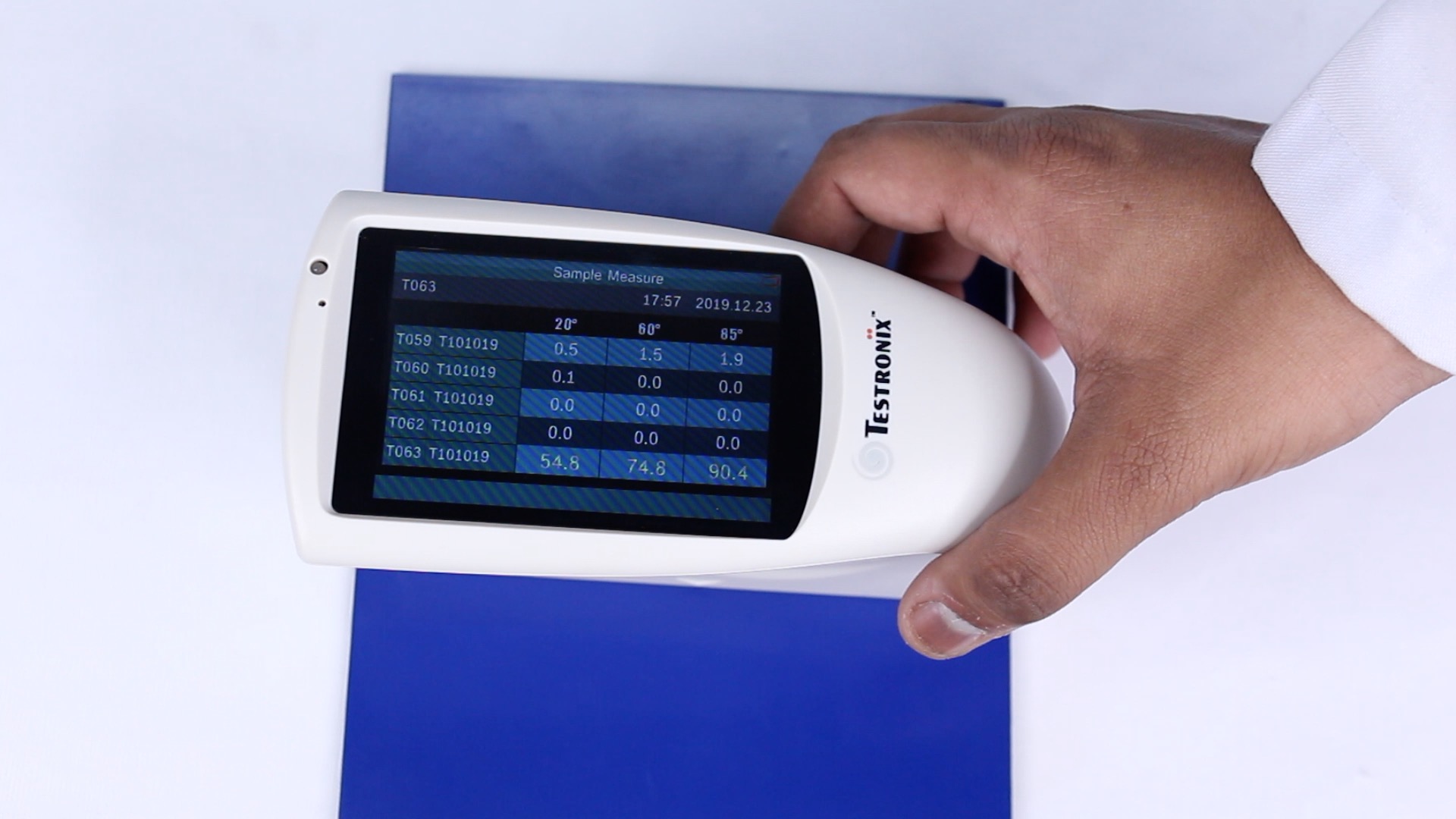

The digital gloss meter can easily help manufacturers in testing products from different angles. This testing instrument will provide accurate gloss measurements from different angles and help manufacturers ensure the accuracy of lab testing results.

Now, let us discuss the benefits of gloss measurement for different materials.

The assessment of gloss is a pivotal factor in appraising the overall quality and texture of a material's surface. A heightened gloss level signifies a sleek and impeccable surface, characterized by minimal imperfections such as scratches, dents, or bumps. Conversely, lower gloss measurements may signal the presence of flaws that necessitate rectification before the material can be considered suitable for use.

In industries where aesthetics profoundly influence consumer perception, such as automotive, cosmetics, furniture, and electronics, maintaining a uniform gloss level across diverse batches is paramount. Employing standardized gloss measurement techniques enables manufacturers to guarantee consistency in the visual appearance of their products, reinforcing a cohesive and high-quality brand image.

Customers often have specific expectations regarding the appearance of a product they are purchasing. For instance, high-end luxury items are expected to have a glossy finish, while products in the industrial sector may require a more matte appearance. Gloss measurement is used to ensure that the final product meets these expectations and satisfies customer needs.

Gloss measurement can also be used to monitor production processes and identify any deviations from the desired gloss levels. By regularly measuring and tracking gloss readings, manufacturers can identify any changes or issues in their production process that may affect the final product's visual appearance.

Gloss measurement is also useful in comparing different materials and selecting the most suitable one for a particular application. For instance, materials with high gloss readings are often used in applications where aesthetics play a crucial role, such as packaging or consumer goods.

In some industries, gloss measurement is not only used for aesthetic purposes but also to improve product performance.

These are the benefits of using a gloss meter, and you can also read more on the significance of gloss meter in different industries.

Testronix gloss meter triangle has been designed with highly advanced features that make it easy for manufacturers to conduct quality tests on the materials with ease. Users can easily measure the glossiness of the surface at different angles including 20°, 60°, and 85°.

Gloss measurement plays an essential role in materials science by providing objective data on the visual appearance of different materials. It helps ensure consistent quality control, meet customer expectations and improve product performance. By using standardized gloss measurement techniques, manufacturers can ensure that their products meet the desired level. If you want to know about gloss meter price or other information then you can give us a call at +91 9313 140 140 or email us at info@testronixinstruments.com.