Reviewed by Anurag Mishra (Sr. Technical Consultant)

A slight error in this very competitive market of food packaging may cause huge financial loss. For industrialists, primarily food industrialists, there is always a constant challenge to ensure that the pouch containing the foods is airtight and leak-proof. Failures in packaging lead to spoilage, contamination, and damage increasing your brand reputation. This calls for a sound solution, one that will not only guarantee quality and endurance for longer but also minimize or dispose of waste.

Enter the vacuum leak tester, an increasingly indispensable tool in determining food pouch leaks. This post takes you through the undisputable benefits of employing a vacuum leak tester, especially for food manufacturers who look forward to improving their packaging operations.

However minute the leak might be, it allows oxygen and moisture to reach the package, making your food products unsuitable for consumption. Here, food packaging is not an envelope, rather, it's a first line of defense in preserving freshness and hygiene.

The effect? Wastage of products, complaints from customers, and possible recalls can pretty much hamper your brand's reputation. That is where a vacuum leak tester becomes handy.

Testronix Instruments is the leader in the industry. With quality testing solutions of over 11 years, Testronix boasts a stellar track record of high-profile clients that operate within diverse sectors. Our commitment to delivering innovative, accurate, and durable testing equipment ensures that our clients meet their operational goals in an efficient manner.

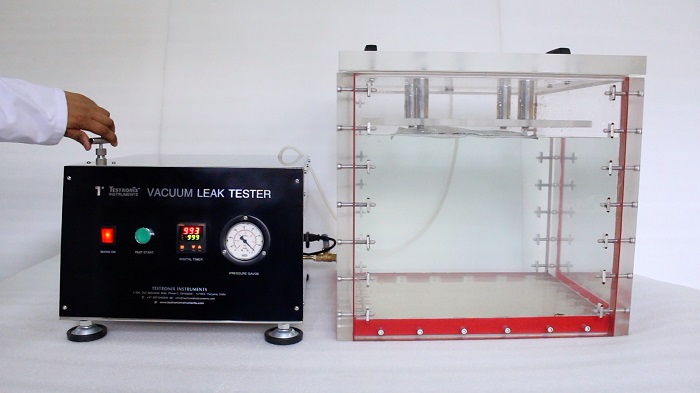

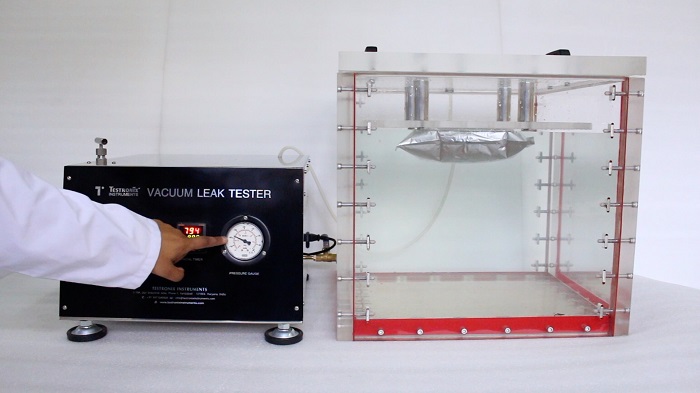

A vacuum leak tester is an instrument specifically designed to detect the smallest leak in a vacuum-sealed food pouch. For this purpose, it applies negative pressure inside the chamber to simulate real-world conditions to ensure that your packaging can withstand transportation and storage stress. Thus, identifying weaknesses in seals and materials will ultimately help in ensuring that your product remains fresh from manufacturing to the consumer's hand.

Not only will it save you money by preventing costly leaks but also helps in saving packaging waste. Without a leak test, food products may get damaged during shipping or inventory storage, and this increases its expense and environmental impact. These risks are eradicated with the use of a vacuum leak tester.

While choosing a vacuum leak tester, industrialists have to look up its specifications to ensure that it would match their operating needs.

The Testronix Vacuum Leak Tester is designed with precision so as to meet the demands in food pouch testing are a pressure range of -1.0 bar to 0 bar, allowing for versatility of testing under different pressure conditions, and its size, test chamber available in various sizes ranging from small pouches to big pouches, thus covering the requirement of volume depending upon the product.

Material Compatibility: Good at testing plastic, laminated, and composite pouches, which means it is good for all types of packing.

Test Mode: It is well-designed with manual and automatic test modes to be useful in its variety of operating modes

Accuracy: It is equipped with highly precise sensors enabling the detection of even minute leaks; there is no chance of packaging failure.

Display: Digital display that is easy to read, which can enhance the monitoring and record-keeping process.

These technical features give you accurate and reliable results all the time, so never does packaging failure happen to your product.

Investing in a vacuum leak tester is not only about quality assurance but also optimizing operations. This is how the Testronix Vacuum Leak Tester can make a difference:

Reduce product waste: You can save up to 15-20% of your product costs by detecting leaks before reaching the consumer. Spoiled goods due to packaging failure are expensive and result in wasted resources for replacement.

Cost Savings in Time: Proper and efficient testing with the Testronix Vacuum Leak Tester saves you precious time in quality checks. More time, therefore, is put forth in scaling the business operations.

Reduced Packaging Costs: The ability to detect weak points in packages means you can pinpoint where materials or processes go wrong, thus reducing the costs made from returns and reworking faulty packages.

Prevent Leaks and Damage to Brands: Early leakage detection will save your business from significant losses in terms of finance and reputation through product recalls. The cost of a vacuum leak tester is but a fraction compared to the headache of a recall.

FAQs

Testronix Vacuum Leak Tester accepts a wide variety of materials including plastic, laminated, or composite pouches.

The testing frequency will depend on your volume of production and quality control steps. But for sure, you should test each batch for any possible leaks.

Yes, because of the very precise sensors used in the Testronix Vacuum Leak Tester, you can be able to detect the smallest leaks that might likely affect product integrity.

This is an investment into the quality of your products, your brand name, and the efficiency of your operations because it ensures leak-proof packaging, delivers products meeting consumer expectations, and, therefore, saves money on product loss and packaging failures. Do not wait for that big packaging disaster; be proactive and secure your operations with the Testronix Vacuum Leak Tester.

Want to enhance the packaging standards while cutting down on costs? Contact Testronix today for a free consultation and demo of the Vacuum Leak Tester.