Reviewed by Anurag Mishra (Sr. Technical Consultant)

Boxes are widely used in different industries to deliver and store products accurately. Thus, testing the compression strength of these boxes is important to ensure accurate products will be delivered to the customers. By conducting box compression tests on these boxes, manufacturers of different industries can easily and accurately measure the durability of boxes when the compression force is applied to them. Testronix is India’s one of the leading box compression tester manufacturers and designs high-quality testing equipment with an advanced set of features.

This high-quality testing equipment has been provided with different models including computerized models, digital models etc. With Testronix box compression testing equipment, manufacturers of the paper and packaging industry can relatively test their products and ensure that quality products will be delivered to the customers.

In this blog, we will share some useful tips to handle the box compression tester carefully. But before that, we will discuss why it is important to maintain a box compression tester.

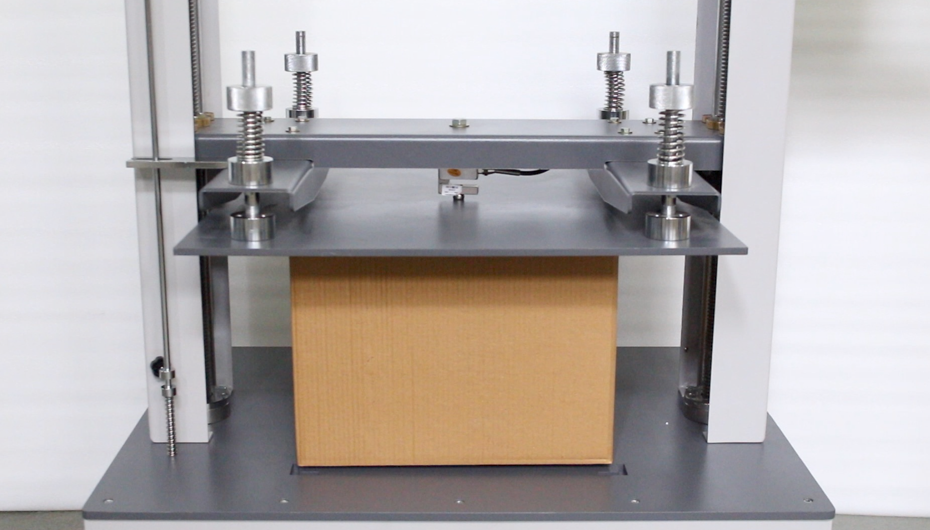

Box compression testers are essential laboratory testing equipment for any packaging manufacturer or distributor. These machines are used to determine the strength and durability of corrugated boxes, which is a crucial factor in ensuring the safe transportation and delivery of goods. In this section, we will provide an introduction to box compression testers, including their purpose, and why it is important to maintain these box-testing machines.

The primary purpose of a box compression tester is to measure the maximum load a box can withstand before it deforms or collapses. This test simulates the conditions that a box may encounter during storage and transportation, such as stacking pressure from other boxes or external forces during handling. By conducting these tests, manufacturers can ensure that their boxes meet industry standards and are suitable for protecting their products during transit.

Routine maintenance is an essential aspect of keeping your box compression tester in top working condition. With regular upkeep and inspections, you can ensure that your equipment is functioning properly and accurately testing the strength of your packaging materials. In this section, we will discuss the importance of routine maintenance for box compression testers in detail.

Ensures Accurate Results:

The primary function of a box compression tester is to measure the compressive strength of packaging materials. If the equipment is not well-maintained, it can lead to inaccurate results, which can have significant consequences for your business. Routine maintenance helps to identify any issues with the machine before they affect its performance, ensuring reliable and accurate test results every time.

Increases Equipment Lifespan:

Just like any other machinery, box compression testers also have a lifespan and require proper care and maintenance to ensure longevity. Regular upkeep helps to prevent wear and tear on critical components such as load cells, motors, and control systems. It also reduces the risk of breakdowns or malfunctions that may result in costly repairs or replacements.

Maintains Safety Standards:

Safety should always be a top priority when operating any machinery. By regularly maintaining your box compression tester, you are ensuring that all safety features are functioning correctly. This includes emergency shut-off switches, protective guards, and alarms that warn operators about potential hazards or malfunctions. You can read more on the useful tips to choose a box compression tester.

Now, let us discuss some important tips for maintaining a box compression tester.

Ensure greasing of the lead screw every three months:

Regularly apply grease to the lead screw of a machine or equipment. The lead screw is a threaded rod that translates rotational motion into linear motion. Greasing helps reduce friction, ensures smooth movement, and extends the lifespan of the lead screw.

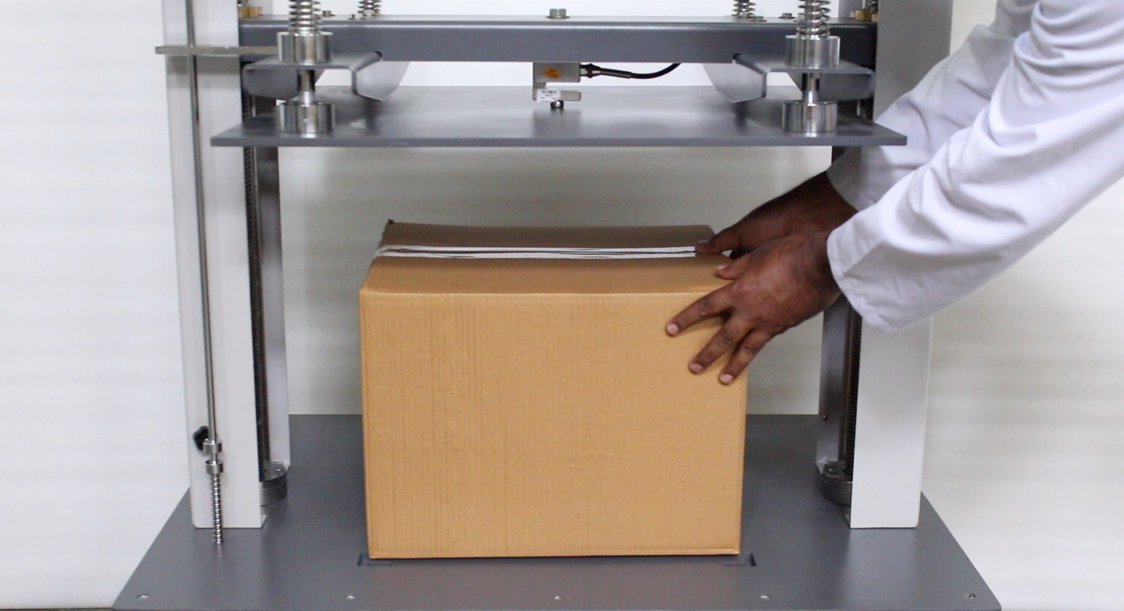

Ensure the right placement of the specimen during the test procedure:

Properly position the specimen or test sample according to the specified guidelines before conducting any testing. Incorrect placement can lead to inaccurate test results, compromising the validity of the test and the reliability of the data collected.

Check the placement of limit switch rings before commencing the test:

Inspect the positioning and functionality of limit switch rings, which are used to define the travel limits of a moving part in a machine. Ensuring correct placement prevents damage to the equipment and ensures that the moving parts operate within safe and designated boundaries.

Tighten the V-belt drive every three months and check it for regular wear and tear. Replace worn-out V-belt immediately:

Periodically tighten the V-belt drive system, which is a common method of transmitting power in machinery. Additionally, inspect the V-belt for signs of wear and tear. If any belts are worn or damaged, replace them promptly to prevent equipment failure and maintain efficient power transmission.

Top up the gear oil in the gearbox annually:

Annually replenish the gear oil in the gearbox of machinery or equipment. Gear oil lubricates the gears, bearings, and other moving parts within the gearbox, preventing friction, wear, and overheating. Regular maintenance ensures optimal performance and prolongs the life of the gearbox components.

Following these maintenance procedures helps ensure the reliability, accuracy, and longevity of the equipment or machinery, minimizing the risk of failures and optimizing overall operational efficiency. Regular inspections and preventive measures contribute to a safer and more productive working environment. You can also give us a call at +91 9313 140 140 or email us at info@testronixinstruments.com.