Reviewed by Anurag Mishra (Sr. Technical Consultant)

The materials that are used in the production of final goods are assessed up on their ductile as well as tensile strength. It becomes crucial for manufacturers of the products to evaluate the mechanical properties of materials before utilizing them in the production process because there are certain materials that are used for different purposes considering their mechanical properties.

Understanding with the help of an illustration, in the case of a tire manufacturing company, assessing the ductile strength to pinpoint accuracy becomes extremely crucial as it determines the ability of the tire to withstand the road conditions, in case the ductile strength of rubber is more than required the tyre of a vehicle might elongate during the travel, leading to punctures and possible jeopardies through accidents.

Similarly, all materials have their own mechanical properties which must be assessed in the initial stages of production to avoid hefty losses due to faulty bulk production in the later stages. One of the finest lab testing instrument manufacturers in the country – Testronix has served the finest one-stop solution called the Tensile Tester. The equipment is designed to determine the tensile & ductile strength of materials with pinpoint accuracy & precision.

The tensile tester is manufactured as a single solution to evaluate the tensile strength of all the materials like metal, fabric, polymer plastics, rubbers, etc. This is because of the ergonomically designed working of the instrument.

The universal tensile tester is offered with an extremely simple testing mechanism as the manufacturer of the instrument followed an operator-friendly approach which is the reason the instrument is offered with an additional accessory.

The additional accessory called the dumbbell cutting press is used for conditioning the specimen by carving it out in a dumbbell-shaped precisely for the conduction of the tensile test.

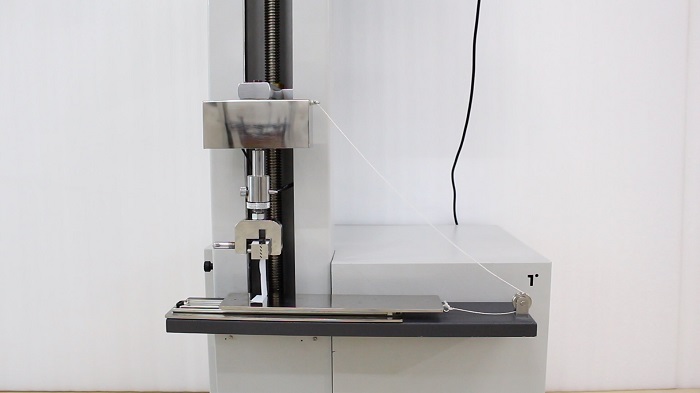

The operator can choose from the wide range of jaws, suitable for the material being tested. After selecting the right jaw, the operator can simply clamp the specimen in among the grippers firmly which ensures no slippage of the specimen.

After firmly clamping the specimen, the operator begins the test wherein the lower jaw moves downward and the upper jaw clamping the specimen remains stationary at the top. The lower jaw can move as far as 700 mm from the beginning point i.e. 25mm.

The away movement of the lower jaw from the upper jaw forces an exertion of pull force on the specimen which leads to either breaking of the specimen after suffering the peak load or elongation of the specimen.

The microprocessor-based digital display associated with the control panel indicates the maximum elongation and the peak load that the specimen could withstand before breaking.

The operator can simply assess & evaluate the results and also keep track of records due to the memory hold feature imbibed within the control panel.

This is how the universal tensile machine conducts the tensile test over various materials with no or minimal hassle to the operator and provides maximum accuracy even with repeatable testing measures.

The instrument is equipped with top-quality attributes that encourage the operator to achieve higher accuracy with a seamless testing experience.

The universal tensile machine is equipped with high-end attributes that aid manufacturers in achieving pinpoint accuracy.

The most prominent feature of the universal testing machine is the incorporation of variable jaws such as vice, zig-zag, wedge, diamond, etc. for different material types that ensure zero slippage of the specimen during the conduction of the test.

The lab testing instrument has a cross-head gripper separation of 700mm that ensures the testing of even bigger and highly elastic materials.

The conduction of the tensile test becomes even easier with the perfect conditioning of the specimen, provided along with the instrument called the dumbbell cutting press.

The microprocessor-based digital display is equipped with elongation & peak load indicators that make it easy for the operator to record results and the memory hold feature helps the operator keep track of the results.

The universal testing machine is also offered with a highly advanced control panel that is offered with feather touch controls that enhance the testing experience by allowing the operator to perform the testing single-handedly and thus expedite the testing process.

Attain the finest quality lab testing instruments from Testronix right away by placing a phone call at +91 9313140140. To seek knowledge and information regarding the wide range of products that we deal in, you can consider surfing our website.

We would highly appreciate it if you could share your feedback on our e-mail id at info@testronixinstruments.com. We hope that we can serve you the best ever with the assurance of the Testronix Group.