Reviewed by Anurag Mishra (Sr. Technical Consultant)

Precise moisture measurement is an important practice in industries such as food processing, pharmaceuticals, agriculture, and chemicals. High or low moisture can degrade product quality, lead to compliance issues, or result in storage difficulties like spoilage, clumping, or decreased shelf life.

Standard testing procedures for moisture are usually time-consuming and susceptible to human error, which makes them impractical in today’s production needs. This is where moisture analyzer instruments provide a sure answer. With their ability to produce quick, accurate readings of moisture content, they enable manufacturers to keep production consistent, ensure quality, and avoid waste.

Moisture Analyzer is a laboratory-based instrument and provides a quantitative measurement of moisture content, typically using the loss-on-drying method. It is extensively used in manufacturing, research and development, or testing materials for various industries like food, pharmaceuticals, or plastics. In industries, product performance, stability, and compliance with regulatory requirements are highly dependent on a moisture analyzer.

Also read: What is moisture meter?

Moisture analyzer, or loss on drying (LOD), works on the principle of thermogravimetric analysis; the determination of the weight loss of a sample when dried. A sample is dried to vaporize the water and subsequently determine the moisture content in terms of the difference in weight before and after drying.

Moisture Analyzer is calculated using the formula:

%Moisture=Wet Weight-Dry Weight/Weight Weight * 100

Where:

Dry Weight = Final weight of the sample after drying

The result gives the percentage of moisture in the original (wet) samples.

The moisture analyzer is primarily used to measure the amount of water or moisture present in a substance, which can significantly influence the behavior and properties of materials during manufacturing, storage, and distribution.

In the food industry, moisture analysis is critical for ensuring consistency, shelf life, and regulatory compliance. Excess moisture can lead to microbial growth, spoilage, and weight-based pricing discrepancies, while too little moisture can affect texture and consumer acceptability. Moisture analyzers enable food producers to maintain the ideal balance, ensuring the final product meets both quality and safety standards.

In the pharmaceutical industry, accurate moisture content is essential to guarantee the chemical and physical stability of drugs. Moisture-sensitive ingredients may degrade or change properties when exposed to improper conditions. A moisture analyzer helps ensure dosage forms remain within acceptable limits, thereby meeting stringent quality control protocols such as those defined by USP, FDA, and GMP.

In chemical and petrochemical applications, moisture analyzers are used to maintain the stability and reactivity of compounds. Many chemical reactions are moisture-sensitive, and improper moisture levels can lead to inconsistent yields or hazardous outcomes. Thus, real-time and precise moisture monitoring is vital during both formulation and storage.

In agriculture, moisture analyzers are used to measure the moisture in grains, soil, fertilizers, and other organic materials. This information is crucial for determining harvest timing, storage conditions, and pricing, especially in commodities where moisture levels affect product weight and market value.

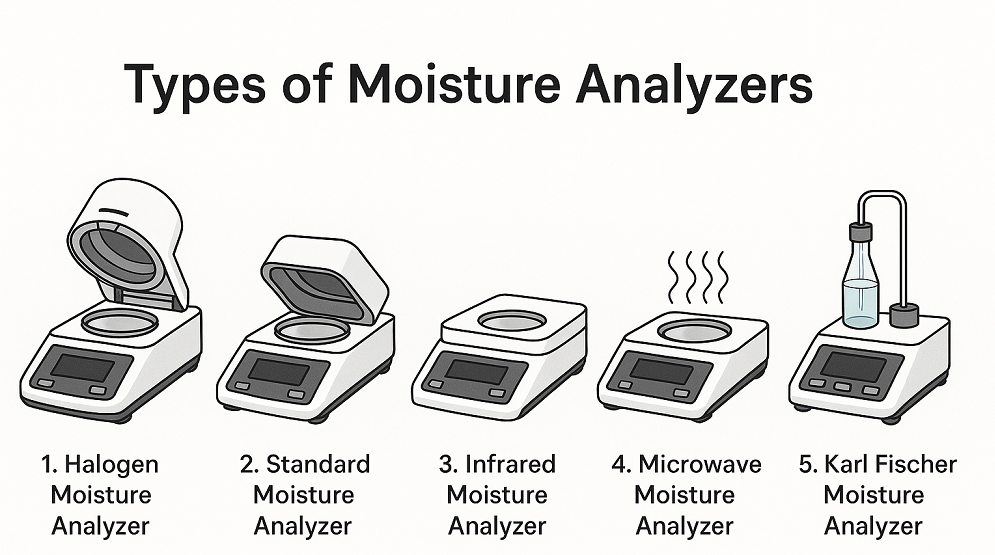

There are mainly two types of Moisture Analyzers based on the heating methods: Halogen and Standard moisture analyzers. Some other kinds of moisture analyzers such as Infrared Moisture Analyzer, Microwave, and Karl Fischer Moisture Analyzer.

A Halogen moisture analyzer is a lab equipment that measures the moisture level of a sample by heating it using a halogen lamp and recording the weight loss as the water evaporates. It's a thermogravimetric technique that gives a rapid and precise method to analyze moisture content in materials.

Standard (ceramic) moisture analyzer is a thermogravimetric analyzer utilized to find the moisture content within different substances by heating the test sample and calculating the weight loss. Ceramic heating elements serve as the major heat source in these analyzers.

The ceramic moisture analyzer is based on the principle of thermogravimetry, which includes heating a sample until its moisture content evaporates and then determining the weight percentage lost in the process of evaporation.

An infrared moisture analyzer is a tool for finding out the moisture content of a sample by measuring the weight loss by evaporation brought about by infrared heating. It applies infrared radiation in drying the sample rapidly and effectively, making it a quicker alternative to oven drying.

A Microwave Moisture Analyzer is a machine that employs microwaves to rapidly and precisely calculate a material's moisture content. It accomplishes this by bombarding the sample with microwaves, causing the water molecules to get heated and evaporate. The weight change resulting from the loss of moisture is then utilized in calculating the moisture content.

A Karl Fischer moisture analyzer is a lab device employed to precisely measure the water content in a substance. It applies the Karl Fischer titration principle, which relies on a chemical reaction of the water with a reagent that holds iodine, sulfur dioxide, a base, and a solvent. The analyzer measures the quantity of water present by measuring the quantity of reagent used in the reaction.

When selecting a moisture analyzer, some of the important features to look at are weighing capacity, temperature range, type of heating, data management, and user-friendliness. Accuracy, repeatability, calibration, and durability are also very crucial.

The weighing capacity is the maximum sample weight that the analyzer can weigh. It is normally measured in grams (g). Increased weighing capacity makes it possible to analyze larger samples, which can enhance the representativeness of the data. Nevertheless, for the majority of lab-scale use, between 50g and 200g capacity is adequate.

These devices dry the sample with heat, and the temperature range defines the upper and lower limits of the heating the machine can achieve, usually between 40°C and 200°C.

Various materials call for different drying temperatures based on their composition.

The heating type influences the rate and effectiveness of moisture evaporation. Heating element selection affects drying time, energy consumption, and applicability to particular sample types. Some common types are:

Halogen Heating: Rapid and even heating, widely used in rapid moisture analysis.

Infrared Heating: Mild and appropriate for fragile samples, but slower.

Ceramic Heating: Cheaper, but slower and less even than halogen.

Data management is now a key function in analytical instruments, such as moisture analyzers, in contemporary laboratory and industrial environments. Apart from assuring safe storage and retrieval of test data, it also aids process efficiency, regulatory compliance, and quality assurance.

Intuitive interfaces, touch-sensitive control, easy-to-use menus, and pre-set drying modes all play a role in ease of use. Tools with step-by-step instructions, live status displays, and low calibration requirements minimize operator mistakes and training. This is particularly crucial in applications involving several users or multiple method changes.

Moisture Analyzers consist of several steps, such as: sample preparation, loading the sample, setting parameters, results & interpretation, etc.

Here is a detailed description of the steps:

Weighing the Sample: Carefully weigh the sample on a balance and note down the initial weight. This initial weight will be taken as a reference during the analysis.

Loading the Sample: Put the sample in the moisture analyzer pan and ensure even distribution. Securely close the lid to ensure that no heat is lost while analyzing.

Setting Parameters: Enter the required parameters into the moisture analyzer, including desired temperature and analysis time. The parameters will depend on the kind of material being analyzed.

Initiating the Analysis: Begin the process of moisture analysis. The moisture analyzer will be adding heat to the sample and will be keeping a continuous check on weight change until a steady endpoint is obtained.

Results and Interpretation: When the analysis is finished, the moisture analyzer gives a percentage of the moisture content of the sample. Interpret results about your industry requirements and quality standards.

Calibration and Maintenance: Calibrate the moisture analyzer daily using standard reference material. Regular maintenance, including cleaning and checking, is necessary to produce accurate and reliable results.

The cost of a moisture analyzer instrument is determined by features, technology, and brand. Entry-level units can range from ?40,000–?60,000, whereas high-end analyzers with halogen heating, touch screens, and connectivity can range from ?1 lakh or above. It also varies with precision, drying rate, and industry certifications.

In conclusion, moisture analyzers are crucial equipment for accurate moisture content measurements in various industries. Knowing their working mechanism, models, and specifications assists in making the right selection. Although costs differ depending on technology and functionality, a good-quality analyzer is worth the investment for accuracy, efficiency, and ultimate value in quality control operations.

If you are looking for a reliable and high-precision moisture analyzer, explore Testronix Instruments — A trusted choice by industry leaders for consistent and accurate testing solutions.