Reviewed by Anurag Mishra (Sr. Technical Consultant)

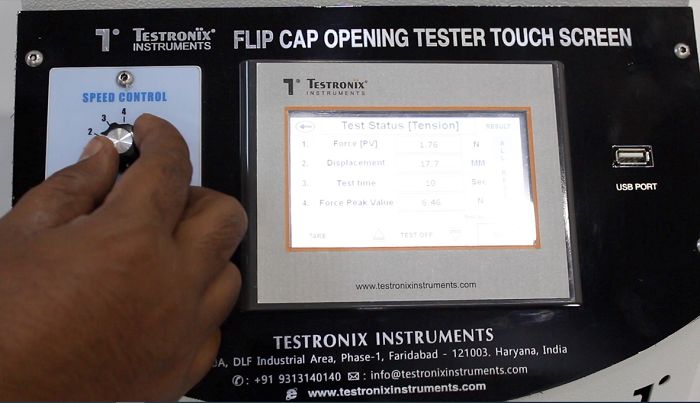

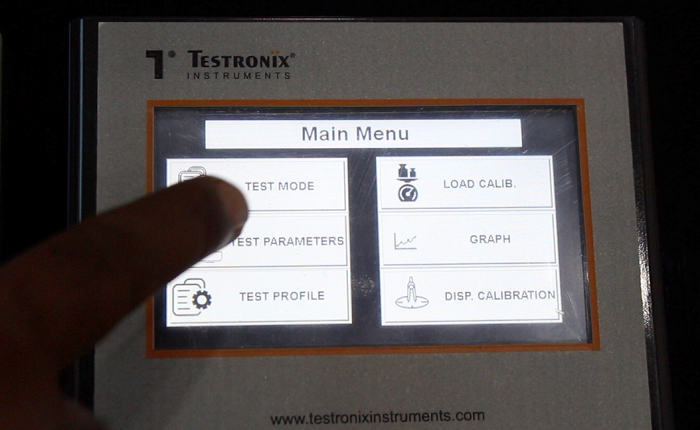

Flip cap opening testers are specialized lab testing machines used in the quality control process of flip-top packaging products. This flip cap opening machine is designed to simulate the repeated opening and closing of flip caps, ensuring that they can withstand the wear and tear of regular use without any defects or failures. With Testronix flip cap opening tester Touch screen manufacturers can easily and effectively test the force required to open flip caps.

This high-quality lab testing instrument offers precise lab testing results. The touch screen display provides various advantages to the user like easy data management, email report facility and 10 sample reading save feature.

In this blog, we are going to discuss a brief about the Testronix flip cap opening tester and how you can easily and effectively make use of this quality testing equipment.

In today's market, where consumers have a wide range of options for packaging, companies must ensure that their products not only look appealing but also function properly. This is where flip-cap opening testers come into play – by testing the functionality and durability of flip-top caps, these machines help manufacturers maintain high-quality standards and ultimately increase customer satisfaction.

What makes flip cap opening testers so essential is their ability to accurately replicate real-life conditions. The testing process mimics the actions performed by a consumer when using a product with a flip-top cap, such as squeezing, flipping, and closing it repeatedly. This means that any potential issues or weaknesses in the design or construction of the cap can be identified before the product reaches consumers' hands.

Testronix is one of the leading flip cap opening tester manufacturers and designs this quality testing equipment at the best prices.

Quality control is a critical aspect of the manufacturing process, as it ensures that products are made to meet certain standards and constantly improve their quality. This is especially important in industries such as food, pharmaceuticals, and cosmetics where the end product directly affects consumer health and satisfaction. In this section, we will discuss the importance of quality control in manufacturing and how flip cap opening testers play a crucial role in ensuring product excellence.

Ensures Product Consistency: Quality control involves monitoring the production process from start to finish ensuring that all products are made according to predetermined specifications. This includes testing raw materials, inspecting production equipment, and conducting various tests throughout the manufacturing process. By consistently checking for any deviations or defects, quality control helps maintain uniformity in product features such as size, shape, functionality, and performance.

Reduces Wastage: Implementing quality control measures can also help reduce material wastage by identifying and rectifying any issues early on in the production process.

Increases Customer Satisfaction: In today's competitive market, customer satisfaction is crucial for business success. Quality control plays a significant role in meeting customer expectations by ensuring that products meet their desired standards of safety and effectiveness.

This indicates the importance of quality control in manufacturing. You can easily and effectively make the use of Testronix flip cap opening tester to test the product quality.

Flip cap opening testers are an essential tool in ensuring product excellence. They play a crucial role in the quality control process of various industries, especially in the packaging industry. These testers are designed to accurately assess the functionality and reliability of flip caps, which are commonly used as closures for bottles, tubes, and other containers.

One of the primary ways that flip cap opening testers contribute to product excellence is by testing the durability and performance of flip caps. This is particularly important for products that are frequently opened and closed, such as cosmetics, personal care products, and food items. By simulating real-life usage scenarios, these testers can determine if the flip cap can withstand repeated use without breaking or malfunctioning. This ensures that consumers will have a positive experience with the product and increases their satisfaction with its overall quality.

Furthermore, flip cap opening testers also play a significant role in detecting any defects or issues with the flip cap design or manufacturing process. These testers can identify problems such as uneven sealing, misalignment of components, or defects in materials that could lead to leaks or contamination. By catching these issues early on during production, manufacturers can make necessary adjustments to improve the quality of their products before they reach consumers.

Another way that these testers contribute to product excellence is by promoting consistency in production. Flip caps need to have consistent specifications for proper functionality and compatibility with different types of containers. By using a tester throughout the production process, manufacturers can ensure that each batch of flip caps meets these specifications consistently. If you want to know more about this quality testing equipment then you can give us a call at +91 9313 140 140 or email us at info@testronixinstruments.com.