Reviewed by Anurag Mishra (Sr. Technical Consultant)

The flexible packaging materials act as a highly crucial protective layer over other packaging materials for durability & enhanced safety of the packed product or item. Flexible packaging materials like laminates, plastic sheets, tapes, etc. are used to provide a firm layer to keep the packaging products intact and safeguard the items inside them.

These packaging layers have a tendency to slip across each other’s surface during stacking & other transit or storage measures that are undertaken by the shippers of the product. Due to the slipping tendency, the products packed inside are extremely prone to suffer damage or get contaminated which results in hampering the brand’s reputation.

Determining the friction levels of a laminated sheet or related material is also important in the printing industry as the printing press is automated and works on a mass scale, in case of differentiation in the friction level of a specimen, the printing ink might get disrupted and can cause huge losses to the manufacturer for faulty production.

To curb this issue and keep the brand reputation high, the leading lab testing equipment manufacturer in the country – Testronix has come up with a solution to ensure the minimum friction levels of these materials when rubbed against each other or other materials. The name of the lab testing instrument that aids manufacturers in evaluating the friction levels is the co-efficient of friction tester.

The instrument is a top-notch device to determine the kinetic & static friction of materials. The highly advanced friction level assessment against variable materials is conducted with such ease & facile with the co-efficient of friction tester that manufacturers from the flexible packaging industry could not resist getting their hands on the device.

The instrument is widely accepted & trusted by manufacturers because of its tripe material testing formula for friction testing that aids the manufacturer & the operator of the instrument to reach high levels of accuracy & determine the friction levels against all hazards that the end product may undergo.

The triple testing refers to the three materials against which the friction levels are tested that are:

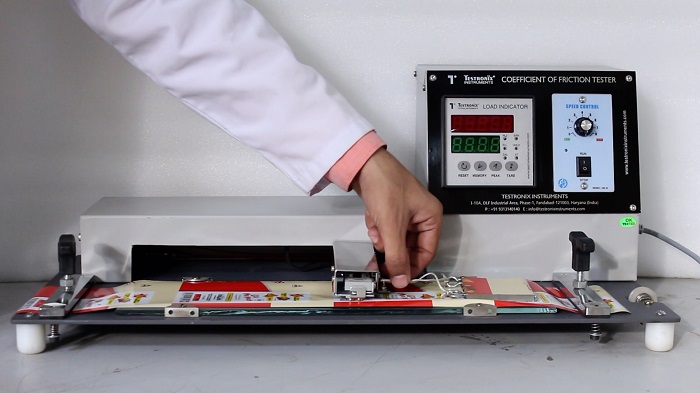

To initiate the friction test in a sample-to-sample measure, the operator has to adjust the sample over the glass slider of the specimen. The operator must make sure that the metal sled is firmly placed over the specimen wrapped around the glass slider. The operator should also make sure that the specimen is clamped firmly enough to avoid any wrinkles and improper or inaccurate test results.

The specimen is also wrapped across the metal sled in the sample-to-sample testing measure. The metal sled slides across the surface of the specimen wrapped across the glass. This results in both the laminations facing each other and sliding across.

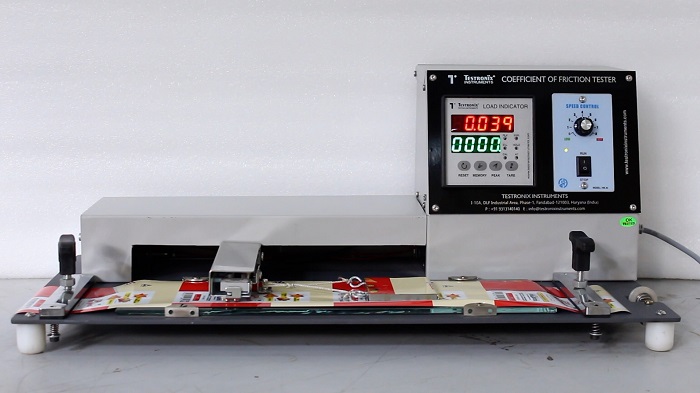

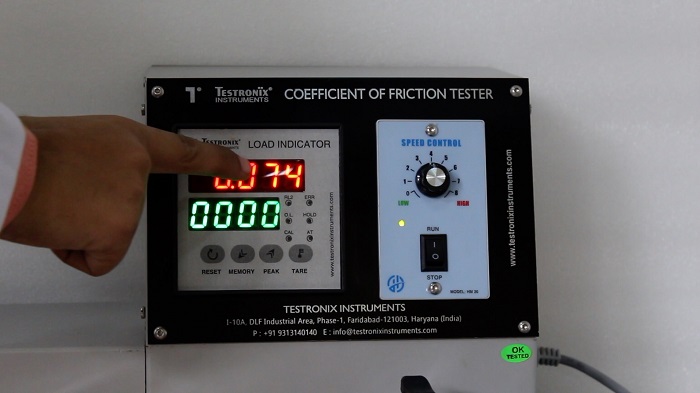

The friction that is developed or caused due to the movement of the sample's surfaces against each other. Both kinetic & static friction levels are indicated on the microprocessor-based digital display. However, to determine the perfect kinetic friction, the operator can keep track of the indicated values and make an analysis out of it.

The friction tester also conducts a metal-to-sample test where the metal sled is not wrapped with the specimen and the metal sled is slid across the specimen and the operator evaluates the results of dynamic & static friction.

Similarly, the friction tester conducts the glass-to-sample test wherein the specimen is wrapped on the metal sled and sled across the glass top of the instrument, enabling the operator to attain the results of the specimen-to-glass testing results on the microprocessor-based digital display of the instrument.

This is how the coefficient of static friction conducts the triple-way testing with different materials to aid the manufacturer in identifying the correct and accurate friction values whether static or dynamic.

There are certain specifications of the instrument that should not be overlooked and must be considered before getting your hands on the equipment.

To determine the static & dynamic friction levels of the flexible packaging materials against variable materials, get yourself the co-efficient of friction tester right away. To book now, give us a call at +91 9313140140. For any query & question reach out to our website or e-mail us at info@testronixinstruments.com.