Reviewed by Anurag Mishra (Sr. Technical Consultant)

There are numerous manufacturers that resort to pouches and other flexible packaging material with seal integrity to pack their items. Examples of these items can be toiletry sachets, and perishable items like wafers, chips, chocolates, etc. It becomes highly important for manufacturers from these industries to take full care of their packaging to ensure that the end consumer does not have to compromise on quality at all.

It becomes crucial for manufacturers to make sure that the packaging is up to the mark, therefore these manufacturers take certain precautions by testing the packaging before commencing with mass production to avoid losses due to deprived quality.

One such quality aspect of testing the packaging materials is to determine the leakage (if any) by deflating the pouches through a vacuum medium. This determines the seal integrity of the packaged items.

To aid manufacturers in assessing & evaluating leakages in the packaging materials. Testronix has brought up a top-quality lab testing instrument called the vacuum leak tester digital. The instrument is highly advanced equipment designed to aid manufacturers in indicating leakages within specimens and thus provide maximum consumer satisfaction by enhancing the overall quality of the product.

Going through the functioning process of the instrument will help manufacturers have a better understanding of the instrument and will assist them in conducting the tests correctly.

The vacuum leak tester digital is a top-notch lab testing instrument, precisely constructed to help manufacturers in indicating the leakages in their packaging pouches or materials.

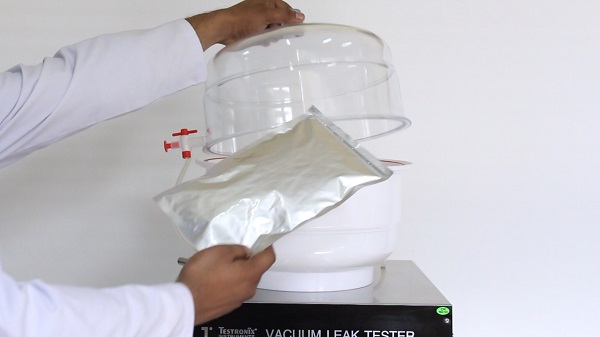

To check the seal integrity of pouches, the first and foremost step is to place the sample in the dedicated desiccator bowl. The desiccator bowl is an enclosed chamber with acrylic walls where the testing is performed.

After placing the chamber in the desiccator bowl, the operator must make sure that the desiccator lid is firmly closed because, in the case of air pressure leakage, the obtained results will hold no accuracy.

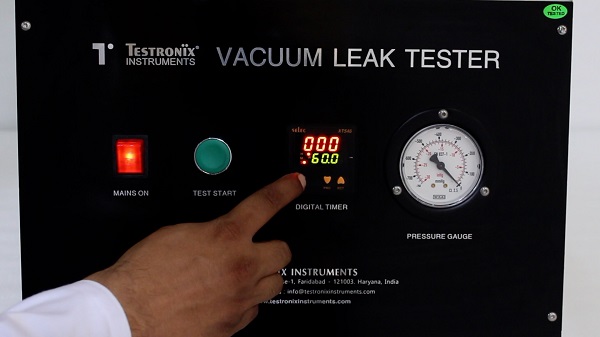

The operator can simply adjust the air pressure within the desiccator with the help of a flow controller associated with the outside of the vacuum leak testing instrument.

The operator can adhere to the dial gauge for monitoring the air pressure and also attain the result recording with the help of the microprocessor-based digital display.

The mechanism of the instrument is based upon simple science wherein, if there is an exertion of pressure outside the specimen, it will create a vacuum inside the specimen. This will result in the vacuum forcing pressure on the walls of the specimen and thus inflating it from the inside, if there is a lack in the seal integrity the specimen packaged item will simply leak out of it or the vacuum will leak out of the specimen and thus deflating.

This is how a vacuum leak test is conducted on the vacuum leak tester digital. The vacuum leak tester manufacturer has made the instrument, a feature-rich product to ensure facile testing.

The vacuum leak tester digital offers a variety of high-quality features that assist them in functioning the device and achieving accurate testing results over & over again.

The instrument is imbibed with acrylic see-through walls to allow the operator to keep a check on the specimen during the course of testing at all times.

The microprocessor-based digital display also allows the operator to keep track of all the records without any hassle at all, these results can be recorded and critically analyzed with the previously obtained results to draw a line of comparison.

The instrument offers a 100% assurance of insulation within the desiccator to allow manufacturers to attain maximum accuracy due to the insulated chamber with the help of a desiccator lid.

The vacuum leak testing instrument also offers an inbuilt vacuum pump to avoid the intervention of external factors and thus ensure maximum accuracy at all times during the test.

The instrument is also equipped with a changeable timer that allows the operator to set the maximum time for the conduction of the test. The timer can be adjusted into different units like hrs: mins: secs.

All these top-quality and high-end features combine together to provide seamless functioning with an accuracy-driven approach to the instrument and provide consumers with the highest quality possible with no compromises at all.

There are certain questions about the instrument that are necessary to be answered to eradicate all sorts of confusion among manufacturers from the industries that utilize or require a product like the vacuum leak tester digital.

Ans. The vacuum leak tester is designed with engineering brilliance as it determines the seal integrity of packaging items like pouches & sachets. These sachets carry products & items for the end consumer but in case of a leakage in the pouch, the brand value of the company will be directly affected causing huge losses.

Therefore, to assess & evaluate the seal integrity of these pouches and avoid any leakages during the final stages, the vacuum leak tester is the simple solution to look forward to.

Ans. The SI unit to derive the results from the microprocessor-based digital display associated with the instrument is QL + 1 m Bar.I/s

Get your hands on the highly advanced and amazingly designed lab testing instrument simply by visiting our website right away. To know the vacuum leak tester price you can simply place a call at +91 9313140140 or directly e-mail us at info@testronixinstruments.com.

As the leading lab testing manufacturer in the country, it is our duty to serve you with quality as well as a seamless testing experience. We hope to see you grow more towards accuracy.