Reviewed by Anurag Mishra (Sr. Technical Consultant)

The raw materials that are utilized in the production process of numerous items & products are tested before consumption to make sure that they are of a certain quality.

The manufacturer of items and products has to utilize raw materials and has an obligation to provide absolute quality to ensure maximum consumer satisfaction. the quality of the end product will only be up to the mark when the foundation laid down by the raw materials is good enough.

This urges manufacturers from various industries to keep a check on all the raw materials that are being utilized under various testing schemes. This aligns with the idea of Testronix to provide quality to each & every individual by eliminating discrepancies at the initial production stages.

The raw materials react differently to outdoor exposure as compared to the indoor setting. This is because of the degrading elements present in the atmosphere which are UV rays from the sunlight, moisture in the environment that causes rusting, etc.

It becomes pivotal for the manufacturers to make sure that the finished product is durable against these elements for long-term work. Testronix Offers a UV light accelerated weathering chamber that is designed to simulate real-life environments around the specimen and assess its reaction to clear all the uncertainties off the list at an early stage itself.

The UV light accelerated weather chamber has an interesting working module that should not be overlooked.

The instrument follows a total of 3 cyclic mechanisms to measure the reactions of the raw material being tested under extreme climatic conditions.

To commence the testing, it is important to place the specimen within the inside chamber of the instrument.

Once placed, it is necessary for the operator to close the chamber’s door firmly in order to avoid any leakage of insulation or inaccuracy of results because of the intervention of external factors.

The first cyclic mechanism is to assess the specimen under dry and elevated temperatures. This ensures the durability of the tested raw material against the heat of summers with scorching sunlight that impact the health of the specimen with UV rays. The UV rays are simulated by CFL monochromatic & UV lights which are uniformly spread across the specimen.

The second cyclic mechanism is called condensation. The environmental test chamber contains a reservoir tank that carries demineralized water. The water is transported to the testing chamber through the inlet port. The environment of the inner chamber is taken over by a simulated condensed atmosphere and the reaction of the raw material to the same can be determined under CFL & UV light rays.

The third cyclic mechanism is called the spray mechanism. Under this mechanism, the specimen is tested against corrosion by creating a humid atmosphere with the help of the demineralized water spread across the specimen through water sprinklers. The testing is performed evenly due to the presence of rotary panels that ensure that the specimen is tested uniformly from all ends.

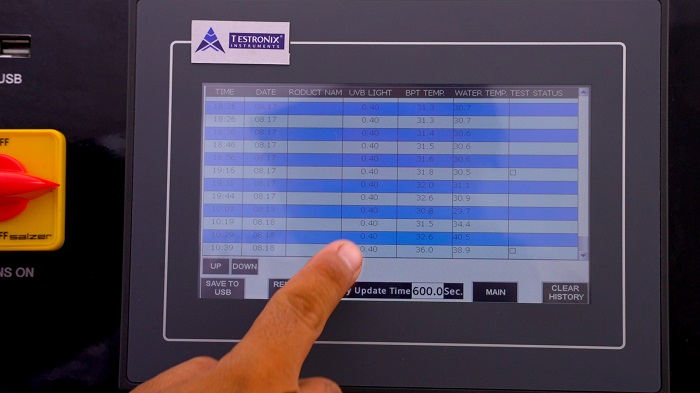

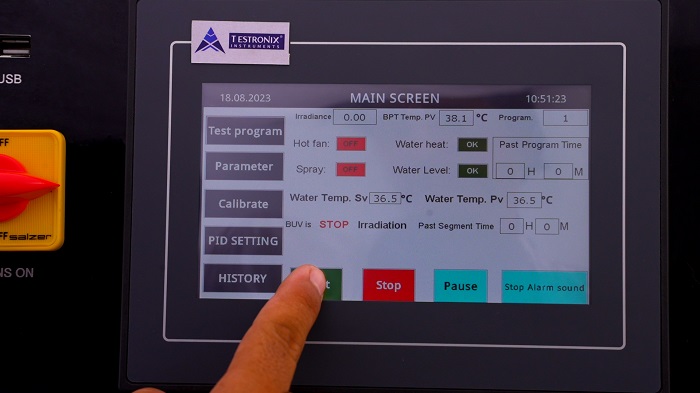

The operator can simply adjust the time & temperature of the testing process as per compliance with designated standards.

This is possible due to the incorporation of an LCD screen which promotes single-handed adjusting and thus hassle-free testing.

There are various advantages of accelerated weathering machine that comes along the package.

The UV accelerated weathering chamber is equipped with a lot of features that ensure safety, accuracy, single-handed operations & expeditious testing.

First & foremost are the safety features that are incorporated as alarms. The instrument has creep-age alarms, water-breaking alarms, overloading alarms & over-temperature alarms to indicate the operator in case of any faulty measures.

The environmental test chamber has a robust stainless steel construction that safeguards the instrument from any kind of rusting by adding anti-corrosion properties to it.

The accelerated weathering machine also offers an HMI-based touchscreen that helps the operator profile the specimen, indicate & determine the result as well as keep track of previously achieved records and compare them with current ones for analysis.

The instrument contains monochromatic lights along with fluorescent lights amalgamated with UV technology which are assembled in a way that derives equal spread and thus ensures accurate results.

To get yourself a taste of futuristic lab testing instruments, you can stumble upon our website right away. For further information and knowledge regarding the UV accelerated weathering chamber, do not wait any longer and give us a call right away at +91 9313140140 or you can write to us via e-mail at info@testronicinstruments.com.

Testronix would love to serve you with our finest lab-testing products made with precise engineering and your belief in the company.