Reviewed by Anurag Mishra (Sr. Technical Consultant)

The usage of plastic preforms has increased rapidly with the rising demand for plastic products all across the globe. These products can be harmful to the environment if not manufactured properly as they take years to decompose completely, therefore manufacturers of plastic PET & preforms have to certainly adhere to the processing of each & every product with absolute diligence.

These preforms are converted to final products by melting and undergoing heat treatment and are developed as preforms through the melting of polymer granules & resins. The conversion of these preforms into a precise & perfect product shape & size requires a lot of precision which can only be possible if the operator undertakes each & every measure with utmost accuracy and there are no uncertainties or stress within the preform.

Although manufacturers undertake an approach of checks & balances, there are instances where stress & lapses are overlooked or missed while melting the polymer granules into preforms. To assess & evaluate the stress in these polymer preforms, it becomes vital for manufacturers to use a lab testing instrument designed for the same.

The finest & largest lab testing manufacturer in the country – Testronix has come up with the most outstanding lab testing equipment called the polariscope strain viewer. The instrument is designed to serve manufacturers a precise & accurate viewing condition for determining the stress & strains over a preform. Performing this test is an extremely crucial step for manufacturers so that all the incompetencies of the preform can be avoided at the early stages and thus the scope of losses due to mass production that industries go through is also avoided.

Understanding with an example, you might have observed the re-shaping of glass bottles or glass specimens into aesthetically pleasing bottles at elevated temperatures by heat treatment, these bottles are tested on their quality before performing such crucial stunts as there are instances when a glass specimen is uneven i.e. at the preform stage, which makes it difficult for the manufacturer to reshape an uneven preform product as the durability & quality of the product gets compromised.

The Polariscope strain viewer is an extremely easy-to-use testing instrument that has gained the trust of manufacturers all across the globe due to its high-end lighting conditions and expeditious testing measures.

The Polariscope glass inspection & plastic inspection machine is designed to aid manufacturers in achieving accurate results while determining the strain & stress in polymers without delaying the manufacturing process.

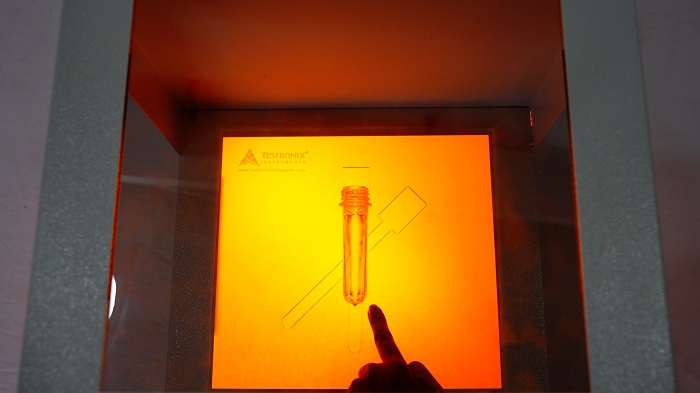

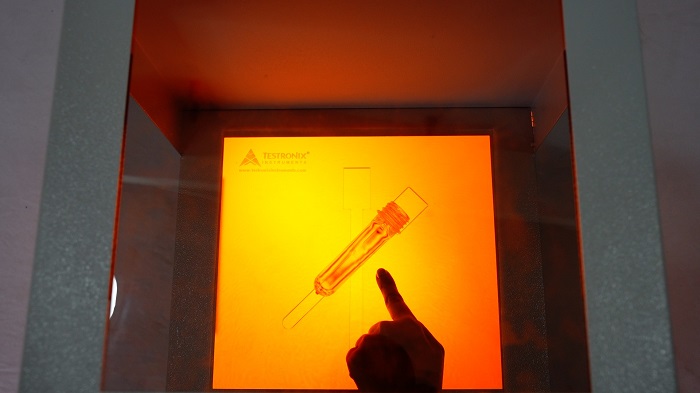

To initiate finding the irregularities in a preform material the operator has to place the sample on the carved-out curvature on the sample holding platform associated with the polariscope above the light assembly.

The instrument is equipped with two angles of testing for precise & accurate testing. The two testing angles are 90 degrees and 45 degrees. The sample is placed on each angle one by one and tested under certain light conditions.

The light condition includes a white light spread across the testing platform, across the specimen as a CFL light bulb for brightness and a clearer picture of the uncertainties. However, the uncertainties of the instrument are exposed by the sodium lamp which is an amalgamation of red lasers passing through the sample exposing the strains & stress areas to the white light.

The instrument offers the operator a wide viewing area to enhance the visualisation and achieves high levels of accuracy in determining irregularities of the preform.

The lab testing instrument allows the operator to inspect the preforms with pinpoint accuracy by providing a chart that states all the inaccuracies that might occur and how the preform looks if that uncertainty is present. The operator can simply adhere to the chart and carry out a clear comparison between the accurate & inaccurate samples.

Conducting this test with the help of the polariscope glass inspection or plastic inspection positions the manufacturer in an extremely comfortable state as this not only determines the uncertainties but also provides a lot of other beneficiaries to the operator.

The Polariscope strain viewer is equipped with a lot of quality attributes that simplify the undertaking of testing measures and in turn help manufacturers in the:

To assess & evaluate the uncertainties of a preform in order to avoid further faults in the manufacturing process, you can get your hands on the highly advanced lab testing instrument – the polariscope strain viewer.

To know more about the polariscope price and the polariscope specifications, you can visit our website without any further delay. Get your hands on the fastest testing instrument right away by reaching out to us via phone call at +91 9313140140 or via e-mail with your feedback at info@testronixinstruments.com.