Reviewed by Anurag Mishra (Sr. Technical Consultant)

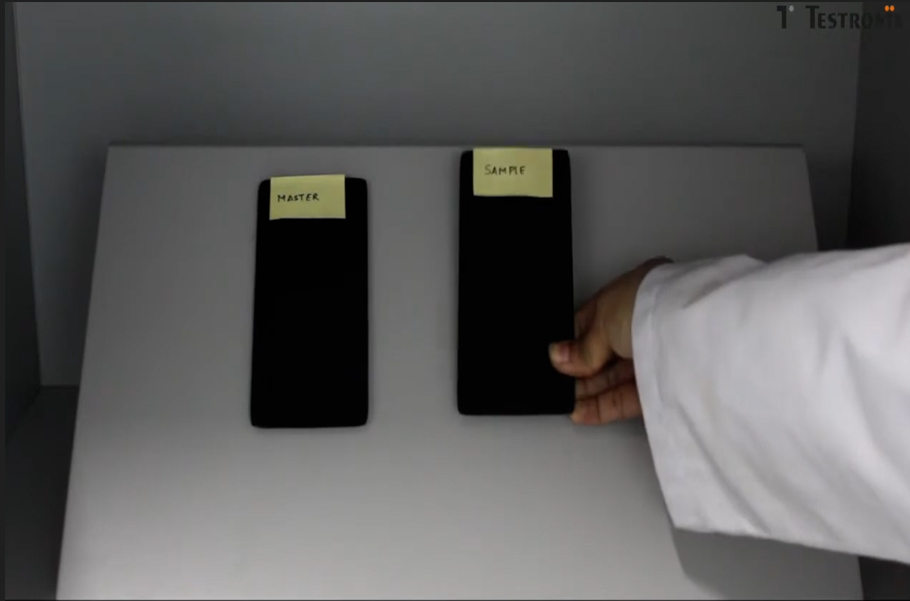

The color of the material can be judged under different conditions such as geometrical angle and under different sources of lights. This exercise explains a standard condition to measure the color difference of same samples under different lighting conditions. If the color quality of the fabric is perfect, then it will appear similar irrespective of different lighting conditions. If a color appearance of a textile product when observed under a spectral power distribution appears to be different when compared to another source of spectral distribution, it creates the problem of Metamerism.

The problem of Metamerism can be the biggest problem in fabrics that need to be verified using the high-quality testing machine to produce high-quality of fabrics. One of the best testing machines which are widely used to measure the color quality of fabrics is different lighting conditions and to eradicate the problem of metamerism is color matching cabinet.

Color matching cabinet – Spectrum Asia is a high-quality color matching device which is used in numerous industries for almost all applications that require color consistency and quality. It is designed for the visual evaluation of color differences under standardized and controlled lighting conditions.

Color Matching Cabinet Spectrum Asia provides a standardized and controlled environment for visual assessment of colors. The color matching cabinet is used to replicate true color. It allows the user to evaluate color samples under different light sources i.e. artificial Daylight (D-65), Cool White Light (CWF), Ultra Violet Black Light (White & Fluorescent Dyes), Tungsten Filament Light (Domestic Light Matching), TL-84 Light -Troposphere fluorescent Light (Point of Sale).

The use of Multiple Light Sources is the only way to detect – a phenomenon where samples appear to be same under one light source but are distinctly different under another. Color matching cabinets a universally preferred choice for faster, Closer and Accurate Color Matching. The instrument is designed as per standard test methods namely, BS 950, DIN 6173, ASTM D1729.

Accurate color measurement is crucial in the textile industry to ensure consistent and high-quality products. The use of Color Measurement Committee (CMC) standards offers several advantages in fabric color measurement.

CMC provides a standardized method for evaluating and communicating color differences. This means that manufacturers, designers, and suppliers can all have a common understanding of what constitutes an acceptable color match. It eliminates confusion and minimizes discrepancies between different parties involved in the production process.

Using CMC allows for more precise color matching. With its sophisticated mathematical algorithms, it takes into account both hue and chroma differences, providing a comprehensive evaluation of color disparities. This ensures that fabric colors are accurately reproduced across different batches or manufacturing facilities.

Furthermore, CMC enables faster analysis and decision-making processes. By utilizing objective measurements rather than relying solely on subjective visual assessments, time-consuming trial-and-error methods can be reduced significantly. This leads to improved efficiency in production planning and reduces costs associated with rework or rejected materials.

Additionally, incorporating CMC into fabric color measurement helps companies meet customer expectations consistently. By ensuring accurate and consistent colors throughout their product lines, brands can maintain their reputation for delivering high-quality goods that meet or exceed customer demands.

Using CMC facilitates effective communication within the supply chain network by providing clear guidelines for assessing fabric colors. Whether it's between dye suppliers and textile manufacturers or retailers working with multiple suppliers globally – having a universally accepted standard like CMC promotes seamless collaboration and reduces misunderstandings.

You can also read more on how you can easily operate color matching cabinet efficiently. If you need more information about it, then quickly connect with us at +91 9313140140 or email us at info@testronixinstruments.com. Our team of technical experts will contact you.